High Alumina Brick UAL80 - High Alumina Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

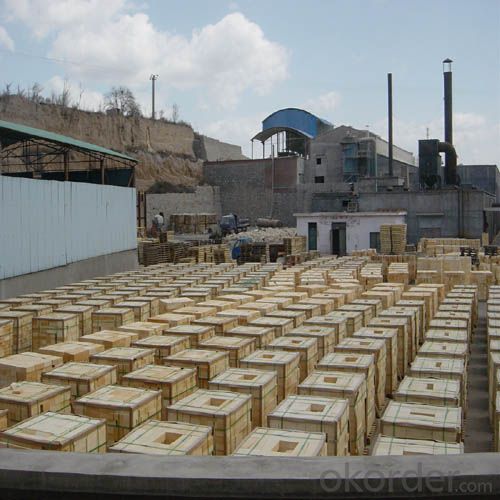

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

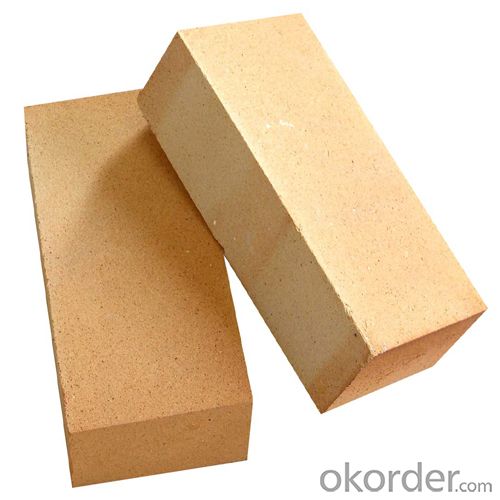

Our high alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It features excellent high temperature mechanics and chemical corrosion resistance.

Features

1.Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Technical Data of High Alumina Brick UAL80 | ||

Physical Properties: |

|

|

Refractoriness | ℃ | 1810 |

Permanent Linear Change(1550℃×2h)% | % | ±0.5 |

Apparent Porosity, % | % | ≤20 |

Cold Crushing Strength | Mpa | ≥50 |

Refractoriness Under Load (T0.6) | ℃ | ≥1500 |

Thermal Expansion, % | % | - |

Density | g/cm3 | 2.7 |

Chemical Analysis: |

|

|

Al2O3 | % | ≥80 |

Fe2O3 | % | ≤1.8 |

Note: | ||

- Q: What are the high aluminum bricks made of?

- It's OK to use corundum bricks and alumina hollow ball bricks to build a furnace,

- Q: What refractory material does cupola lining use?

- It's made of high quality refractory material: 1770 ~ 2000 centigrade.

- Q: How are the high alumina bricks fired?

- Light and high alumina bricks are usually fired in a weak oxidizing atmosphere. In light and high alumina bricks firing, they are often rich in impurities such as R2O, RO, Fe2O3 and so on. They react with Al2O3 and SiO2 at high temperature to produce liquid phase. In the Al2O3 - SiO2 - R2O system, the growth rate of liquid phase increases with the increase of temperature at high temperature. So, because the increase of sintering temperature brings a lot of liquid phase, the decrease of liquid viscosity will lead to the deformation of brick and the decline of brick high temperature function. Therefore, the lower sintering temperature and longer holding time should be adopted in the sintering process dominated by liquid phase sintering. The production practice shows that the same firing temperature can be used for the high grade aluminum bricks. When fired in an inverted flame kiln, it is usually 1430 degrees centigrade and insulated by 40H. The high alumina bricks such as Ill are 1390~1420 degrees centigrade. When the tunnel kiln is fired, they are 1550 and 1450~1500 degrees centigrade respectively. High alumina brick is usually made of weak oxidizing atmosphere.

- Q: What are the common thermal insulation materials for thermal conductivity?

- The single organic insulation material should be the best polyurethane in the field. In accordance with the production process can be divided into on-site foam polyurethane and factory prefabricated rigid foam polyurethane board. The scene is polyurethane foam isocyanate and polyol to cool (polyether or polyester) two components as the main raw materials with additives, the on-site spraying construction with thermal insulation and waterproof function of the rigid foam material.

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: Are there any differences between insulating bricks and refractory bricks?

- As the name suggests, the main role of insulating brick is used to preserve heat and reduce the loss of heat. Such as: Molai S; and the firebrick is mainly used to withstand flame burn. Bricks usually do not contact fire directly, while refractory bricks usually contact the flame directly.

- Q: The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What kind of material is the general metal case?

- Generally speaking, the outer surface of the case is usually made of a steel plate of more than 1 millimeters. The thickness and the material of the steel plate are directly related to the rigidity of the case, as well as the capability of sound insulation and anti electromagnetic radiation. The regular manufacturers of the chassis plate thickness not less than 1.3mm, but there are also some small manufacturers with a thickness of only about 1mm steel, we do not need the ruler to the amount, as long as you put him up, the more weight in the same volume of the chassis is better, in addition, we can also use the finger bomb case shell. If you can hear the crisp percussion sound proof of the casing plate is thin and brittle, if you hear is relatively dull and heavy sound that the chassis material must be good, good general steel plate coated with a layer of thin zinc (bright part), so it can withstand high strength, impact resistance, hardness high elasticity. The frame parts of the chassis are made of high quality materials with high hardness. They are bent into angle shapes or strip shapes. We can shake the chassis frame of the case by hand. Good chassis should be relatively stable, and inferior chassis light is easy to shake. When choosing, we should also pay attention to the outer edge of the case and the edge of the inner bracket. Whether the incision is smooth or not, a good case will not appear in the case of rough edges, sharp edges, burrs and so on. While the poor case appears above phenomenon, often appear when installing the blood splattered". Generally speaking, the chassis must go through the corresponding grinding process before leaving the factory. The edge of the flat plate some burr, edges and corners are rounded, the corresponding fold some corner. When you install such a case, you don't worry about cuts, and some rough, poorly built cabinets tend to scratch your hands.

Send your message to us

High Alumina Brick UAL80 - High Alumina Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords