High Alumina Brick - Industrial Furnace Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

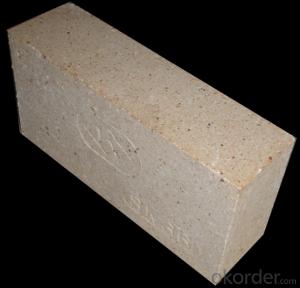

High Alumina Bricks Applied in Industrial Furnace

Composite of High Alumina Bricks

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks Applied in Industrial Furnace

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of High Alumina Bricks Applied in Industrial Furnace

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

High Alumina Bricks Images

Specification of High Alumina Bricks Applied in Industrial Furnace

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks Applied in Industrial Furnace

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q8:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike. It also depends on your using condition and method.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- The brick Pei boring and time. 6, Pei brick kiln installed between the brick and the brick Pei order, Pei and kiln top, kiln wall gap etc.. 7, high alumina brick kiln plan, and the lack of edges and corners of the scene should be avoided.

- Q: How are the high alumina bricks fired?

- Light and high alumina bricks are usually fired in a weak oxidizing atmosphere. In light and high alumina bricks firing, they are often rich in impurities such as R2O, RO, Fe2O3 and so on. They react with Al2O3 and SiO2 at high temperature to produce liquid phase. In the Al2O3 - SiO2 - R2O system, the growth rate of liquid phase increases with the increase of temperature at high temperature. So, because the increase of sintering temperature brings a lot of liquid phase, the decrease of liquid viscosity will lead to the deformation of brick and the decline of brick high temperature function. Therefore, the lower sintering temperature and longer holding time should be adopted in the sintering process dominated by liquid phase sintering. The production practice shows that the same firing temperature can be used for the high grade aluminum bricks. When fired in an inverted flame kiln, it is usually 1430 degrees centigrade and insulated by 40H. The high alumina bricks such as Ill are 1390~1420 degrees centigrade. When the tunnel kiln is fired, they are 1550 and 1450~1500 degrees centigrade respectively. High alumina brick is usually made of weak oxidizing atmosphere.

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- In the meantime, the free silica content of silicon brick is as high as 90% above. Therefore, the most serious damage is silicon brick, followed by clay brick, high alumina brick, magnesia brick and so on.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred.

- Q: Use of high alumina refractory bricks?

- High alumina refractory brick in Al2O3 more, close to neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so alkaline slag ability than acid resistance slag ability less.It is widely used in building blast furnace, hot blast furnace, furnace top, blast furnace, reverberatory furnace and rotary kiln lining. In addition, high alumina bricks are widely used as furnace regenerative checker, pouring system for plug nozzle, etc..

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Brick - Industrial Furnace Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords