High Alumina Brick for Industrial Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Bricks for industrial Furnaces

Composite of High Alumina Bricks for industrial Furnaces

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks for industrial Furnaces

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Acid and alkali resistant

High tensile strength

Resilient to thermal shock

Corrosion resistance

Moisture-proof

Lightweight

Asbestos-free

Wear and erosion resistant

Low creep rate

Application of High Alumina Bricks for industrial Furnaces

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

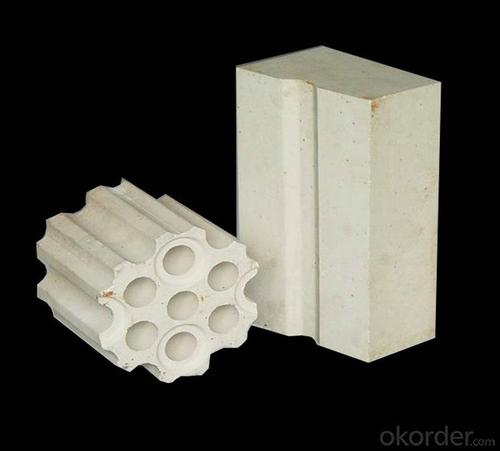

High Alumina Bricks for industrial Furnaces Images

Specification of High Alumina Bricks for industrial Furnaces

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks for industrial Furnaces

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

- Q: What is fireproof concrete?

- Silicate fireproof heat-resistant concrete using temperature can reach 700 DEG ~800 DEG, the main mechanism of its heat is dehydrated calcium hydroxide silicate hydrates series of cement clinker under high temperature, the calcium oxide and slag and mixing activated silica material in the three and two aluminum oxide and the reaction of anhydrous calcium silicate and anhydrous aluminum acid calcium has strong heat resistance, the fire resistance of concrete is a certain. Such as the use of high alumina bauxite and broken bricks, magnesia brick and magnesia for fireproof heat-resistant concrete materials with the highest using temperature can reach 1100 DEG C.

- Q: What are the high aluminum bricks made of?

- The amount of refractory mud accounts for about 6% of the brick weight

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: What refractory material does cupola lining use?

- A class of inorganic nonmetallic materials with a refractoriness of not less than 1580 degrees. Refractoriness is defined as the temperature of a sample of a refractory cone sample that resists high temperature without loading and does not soften and melt down. But only in terms of fire resistance can not be fully described refractories, 1580 degrees of temperature is not absolute.

- Q: Density of high alumina bricks

- High alumina brick by aluminum content is divided into four grades, three grade high alumina bricks content of not less than fifty-five percent, two grade high alumina bricks content of not less than 65, a high aluminum brick content of not less than 75, super high aluminium brick content above 85. As for the high aluminum brick shape, in addition to the standard high alumina brick, high alumina brick and general type, also called special high alumina brick, if the shape is very irregular it is usually called the specific type of high alumina brick, in short, to customized according to the specific use of kiln.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

Send your message to us

High Alumina Brick for Industrial Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords