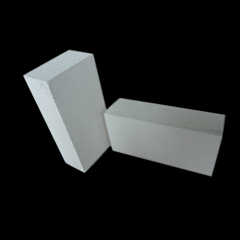

High Alumina Brick - High Quality High Aluminium Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX high alumina firebricks are classified according to alumina content ranging from 48% to 90%.

Specifications

1. High temperature

3. with economical prices

4. Various models and size

5.acid and alkaline resistant

Specifications

1.Apparent porosity max 24%

2.Bulk density min 2.30 g/cm3

3.CCS min 40MPa

4.0.2Mpa (RUL)min 1400

5.Fe2O3 max 1.8 %

Index | LZ-75 | LZ-65 | LZ-55 | LZ-48 | LZ-80 | LZ-85 | |

Refractoriness SK | 38 | 37 | 37 | 36 | 39 | 40 | |

Refractoriness under load 0.2Mpa °C | ≥1520 | ≥1500 | ≥1470 | ≥1420 | ≥1530 | ≥1550 | |

permanent linear change % | 1500°Cx2h | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 |

| +0.1~-0.4 | +0.1~-0.4 |

1450°Cx2h |

|

|

| +0.1~-0.4 |

|

| |

Apparent porosity % | ≤23 | ≤23 | ≤23 | ≤22 | ≤23 | ≤23 | |

Cold crushing strength Mpa | ≥53.9 | ≥49.0 | ≥44.1 | ≥39.2 | ≥55 | ≥55 | |

Chemical composition | Al2O3 % | ≥75 | ≥65 | ≥55 | ≥48 | ≥80 | ≥85 |

Fe2O3 % | |||||||

- Q: What are the high aluminum bricks made of?

- It's OK to use corundum bricks and alumina hollow ball bricks to build a furnace,

- Q: Application characteristics of high alumina brick

- Slag resistance. Due to the high alumina brick products in the three oxidation of two aluminum is neutral and high content, so this material products for acid-base slag corrosion resistance.

- Q: What are the specific raw materials for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: What does refractory consist of?

- According to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: What is the difference between high alumina brick and clay brick?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color. For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: What kind of material is the general metal case?

- We usually discuss the electromagnetic radiation of computer enclosures, mainly RF radiation, followed by MF leakage.Switch signal of RF radiation from computer high-speed leakage, such as one of the energy radiation is CPU frequency, graphics, display output line, keyboard, is the source of the operating characteristics of the computer leaked out, is also the main part of computer security.For the absorption of radio frequency radiation, the best is the use of copper materials, the use of other metals can also, thickness enough on the line.The most vulgar description is that people can sit in the case is a good thing.

- Q: What causes breakage of refractory bricks?

- Refractory brick is a non metal mineral products can be used in the high temperature of 1550 DEG C under belongs to a class of inorganic, used in high-temperature furnace lining materials as protection kiln, which causes damage, usually have these points.Furnace temperature is not clear, there is no corresponding choice of refractory bricks.Physical impact, abrasion and erosion cause damageChemical factors, especially chemical industry, should be made of refractory bricks, which should be resistant to penetration and erosionIV: products from the factory when the factory did not pass the quality inspection standards

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3.

Send your message to us

High Alumina Brick - High Quality High Aluminium Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords