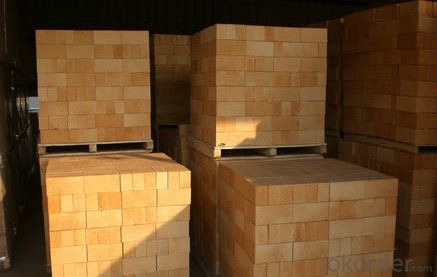

High Alumina Magnesite Brick for Cement and Glass Plant

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Magnesite Brick

Magnesite Brick for Cement and Glass Plant are designed and manufactured as per the different usage parts and working conditions of electric furnace, converter and ladle. Magnesite Brick is shaped by high purity & high compact or large crystalline fused magnesia and high purity graphite as main materials and phenolic resin as binder.

Magnesite Brick is mainly applied for the lining parts of electric furnace and converter. Directly touching molten steel and slag, Magnesite Brick has the advantages of high strength, high slag resistance, good thermal stability and high refractoriness.

Specifications for Magnesite Brick

| Product Item | Magnesite Brick for Cement and Glass Plant | |

| KBL-65 | KBL-75 | |

| Al2O3 % | >65 | >75 |

| Fe2O3 % | 2.0 | 2.0 |

| Refractoriness °C | 1790 | 1790 |

| Apparent porosity % | 24 | 24 |

| Bulk density g/cm3 | 2.45 | 2.55 |

| Cold crushing strength Mpa | 45 | 55 |

| Refractoriness under load KD,°C | 1500 | 1520 |

| Reheating Linear Change % | 1500°C×2h (0.1~-0.2) | 1520°C×2h (0.1~-0.4) |

| Thermal shock resistance ,times (1100°C water cool) | 18 | 15 |

| Application | Industrial furnace temperature sharp parts | Industrial furnace temperature sharp parts |

Features of Magnesite Brick

Low bulk density, low thermal conductivity, good thermal insulation performance.

Refractory category allow direct contact of fire, suitable for various atmosphere.

Good integrity with furnace lining, long service life, easy operation, could be shaped freely.

Typical Application of Magnesite Brick

Furnaces of metallurgy industry, heat treatment furnace.

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace .

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: Introduction of high alumina brick

- Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: The difference between aluminium refractory and magnesia refractory

- Magnesia refractory belongs to alkaline refractory materials refers to refractory products such as magnesia magnesia brick magnesium iron spinel magnesium aluminum spinel magnesia ramming materials and other products of raw materials is the main crystal phase is periclase magnesia products

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Sulphide. A total of more than 200~300 kinds, followed by the type of silicate minerals, the weight of 0.25% of the crust. Chang Fu is an important nonferrous metal deposit, which is an important source of copper, lead, zinc, antimony and so on. It is of great economic value. The main features are: metal luster, color, streak is deep, low hardness, good thermal conductivity, than the major. Another feature is that because sulfides are often associated with magma, it is very easy to oxidize under the surface supergene action. Except for pyrite (6 ~ 6.5 hardness), the hardness is very low. Such minerals pyrite, chalcopyrite, galena, FeS2 CuFeS2, PbS, Sb2S3, stibnite sphalerite molybdenite, cinnabar HgS MoS2.

- Q: How to distinguish the good or bad of the high aluminum brick?

- Weigh the weight of the next block. According to the weight standard, a high alumina brick is 3.9 kg in weight, two in high alumina brick, three in high aluminium brick and 4.5 kg in 4.2. The same grade, the same type of high alumina brick, if the weight of a single brick to this standard, but for high quality high alumina brick, otherwise, can not reach such a weight, it shows good quality. If there is a crack, a large piece of broken angle, four sides of inequality, it is for substandard products.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- If the range of softening temperature exceeds the load, the constants of other physical and chemical indexes will also increase or decrease.

- Q: What is the difference between metal compounds and metal solid solutions?

- Sigma phase belongs to Affirmative system, there are 30 atoms in the unit cell, two element alloy, sigma phase formation is related with the following conditions: (1) the atomic size difference, phase difference between the maximum sigma atomic radius of a tungsten cobalt, the atomic radius difference is 12%. (2) there is a set of cubic lattice elements (coordination number 8), and another component is face centered cubic or dense six square lattice (coordination number is 12). (3) appear in "average number of races" (s+d layer electron number) in the range of 5.7 ~ 7.5. The region of the presence of sigma in the two - element alloy is shown in table 3. In the three element system, the concentration and temperature range of the formation of the sigma phase are affected by the addition of third components. Usually in chromium stainless steel in Fe Cr phase, in Fe - Cr - Mn three yuan, sigma phase iron chromium and chromium can form Mn two element, when the addition of manganese in stainless steel, will promote the formation of sigma phase, and stabilizes the wide temperature range. Many of the Fe Cr alloy elements. The phase temperature range increases. In less than 820C stable Fe Cr phase, silicon promotes the formation of D phase and the stable temperature increased to 900 to 960 DEG C, manganese and molybdenum can improve the temperature stability of sigma phase to 1000 DEG C.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Magnesite Brick for Cement and Glass Plant

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords