High Alumina Brick - High Quality Best Price Insulated Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shaanxi, China (Mainland) | Shape: | Brick | Material: | Alumina Cement |

| SiO2 Content (%): | 0.1~1.4% | Al2O3 Content (%): | 48%-85% | MgO Content (%): | 0.1~1.4% |

| CaO Content (%): | 0.01 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.1~1.4% | Model Number: | DFL-LZ | Brand Name: | CNBM |

| size: | LZ-85, 80, 70, 65, 55, 48 | apparent porosity: | 23% Max | refractoriness: | 1750℃ Min |

| refractoriness under load: | 1420℃ Min | cold crashing strength: | 35 MPa Min | Al2O3: | 48% Min |

| thermal shock resistence: | 4-10 | reheating linear change: | 1450℃x2 +0.1 -0.4 | experience: | over than 15 years |

| quality system: | ISO9001-2008 |

Packaging & Delivery

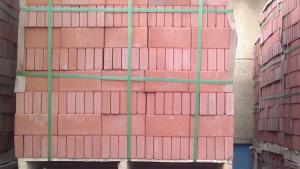

| Packaging Details: | in pallet for sea ship |

| Delivery Detail: | 15-45 days after get customers's deposit |

High alumina bricks

description

Specifications of high alumina bricks

1. AL2O3 : 45%-80%.

2. Can according to customers' requirements.

3. Used for steel ladle lining.

High alumina steel ladle fire brick,Steel ladle brick,Ladle brick

Application of high alumina bricks

High alumina brick is widely used for Widely used in blast furnaces, Hot Blast Stove, Steel ladle lining, Reheating furnace, Cement kiln,Tunnel kiln,boiler, coke oven, carbon furnace,glass kiln , Steel smelting furnace and various kiln lining and thermal technical equipment, etc.

Features of high alumina bricks

1) High-temperature endurable .

2) Good thermal shock resistance .

3) Good resistance to abrasion and corrosion.

4) Good thermal shock and thermal spalling resistance.

5) High mechanical strength.

6) Good volume stability at high temperature.

Physical and chemical index of high alumina bricks

Item | Specification | ||||||

LZ-85 | LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 | 85 | 80 | 75 | 65 | 55 | 48 | |

Apparent density | 23 | 22 | 23 | 23 | 22 | 22 | |

Cold crushing strength | 65 | 55 | 50 | 45 | 40 | 35 | |

RUL | 1600 | 1530 | 1520 | 1500 | 1450 | 1420 | |

PLC | 1500.C*2h | 0.1~-0.4 | |||||

1450.C*2h | 0.1~-0.4 | ||||||

Standards of Type Brick:

| 230mmx114mmx65mm

Product Range: SK32,SK34,SK35,SK36,SK37,SK38

| ||||||

Specail Shape of High Alumina Brick

- Q: What refractory material does cupola lining use?

- A class of inorganic nonmetallic materials with a refractoriness of not less than 1580 degrees. Refractoriness is defined as the temperature of a sample of a refractory cone sample that resists high temperature without loading and does not soften and melt down. But only in terms of fire resistance can not be fully described refractories, 1580 degrees of temperature is not absolute.

- Q: What are the requirements for Rubble backfill height?

- 1, filling thickness is not greater than 50cm.2, filling, the use of layered filling.

- Q: Application characteristics of high alumina brick

- Reheating line change. If the firing temperature of high alumina brick products is enough and the firing time is enough, the volume is stable, the change of the reheating line is small; on the contrary, the residual shrinkage of clay brick products is caused by recrystallization.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- 1. The shell of the furnace is welded by section steel and steel plate. 2, the furnace cover support adopts steel and guide rail combination mobile type. 3. The heating element is made of high resistance alloy 0Cr25Al5 produced by Beijing Shougang Group and arranged on the furnace side. 4, because the bottom bearing adopts high aluminum bricks, the circle center of the furnace set small, inside and outside heating. 5 、 furnace cover adopts hydraulic lifting, motor control, automatic walking. 6 、 temperature control system adopts PID SCR control, high accuracy.

- Q: Density of high alumina bricks

- High alumina brick by aluminum content is divided into four grades, three grade high alumina bricks content of not less than fifty-five percent, two grade high alumina bricks content of not less than 65, a high aluminum brick content of not less than 75, super high aluminium brick content above 85. As for the high aluminum brick shape, in addition to the standard high alumina brick, high alumina brick and general type, also called special high alumina brick, if the shape is very irregular it is usually called the specific type of high alumina brick, in short, to customized according to the specific use of kiln.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: Are there any differences between insulating bricks and refractory bricks?

- Heat preservation brick is to emphasize its heat preservation performance generally, not paying much attention to its refractoriness, but refractory brick is exactly the opposite. Different locations will use different materials, I hope we can choose carefully.

- Q: What is the apparent porosity of high alumina brick?

- In the production of high alumina bricks in addition to the entity, there are many different sizes and shapes of different pores, pores can be divided into three categories: one side closed the other side and the outside world is called open pores, closed in the product not communicated with the outside is called closed pores, penetrating through pores called the few products.

- Q: What is the difference between metal compounds and metal solid solutions?

- Sigma phase belongs to Affirmative system, there are 30 atoms in the unit cell, two element alloy, sigma phase formation is related with the following conditions: (1) the atomic size difference, phase difference between the maximum sigma atomic radius of a tungsten cobalt, the atomic radius difference is 12%. (2) there is a set of cubic lattice elements (coordination number 8), and another component is face centered cubic or dense six square lattice (coordination number is 12). (3) appear in "average number of races" (s+d layer electron number) in the range of 5.7 ~ 7.5. The region of the presence of sigma in the two - element alloy is shown in table 3. In the three element system, the concentration and temperature range of the formation of the sigma phase are affected by the addition of third components. Usually in chromium stainless steel in Fe Cr phase, in Fe - Cr - Mn three yuan, sigma phase iron chromium and chromium can form Mn two element, when the addition of manganese in stainless steel, will promote the formation of sigma phase, and stabilizes the wide temperature range. Many of the Fe Cr alloy elements. The phase temperature range increases. In less than 820C stable Fe Cr phase, silicon promotes the formation of D phase and the stable temperature increased to 900 to 960 DEG C, manganese and molybdenum can improve the temperature stability of sigma phase to 1000 DEG C.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The rotary kiln lining structure of rotary kiln and requirements on refractories calcining active lime according to the general output is divided into Nissan 300t, 400 t, 600 t, 800 t, 1000 t, 12000 t of kiln type, calcining zone temperature at 1350 degrees celsius. The kiln is divided into a discharge end, a cooling zone, a burning zone, a preheating zone and a feeding end, and the temperature of each section of the kiln ranges from 1000 DEG C to 1350 DEG C, and the requirements for refractory materials are different. The kiln refractory materials not only to withstand the high temperature impact, but also need to bear the material erosion, kiln rotation stress produced, so not only on the physico-chemical properties of refractory materials have strict requirements, but also for the construction of brick should be strictly.

Send your message to us

High Alumina Brick - High Quality Best Price Insulated Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords