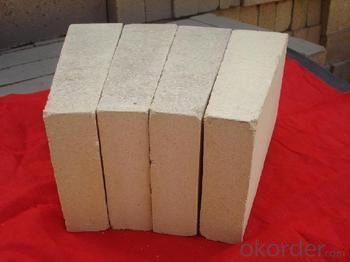

High Alumina Brick for Furnace - Generality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 10 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High alumina brick with unique advanced technology, the temperature of refractoriness under load is normally above 1420~1550°C , which is higher than the fireclay brick and it increases along with the AL2O3 content enhances.

Characteristices of high alumina brick

1. High intensity for pressure

2. Good thermal shock stability

3. Strong abrasion and corrosion resistance

4. High cold crushing strength

5. Excellent abrasion resistance at cold and hot conditions

Advantages of high alumina brick

Good ability of anti-acidity, anti-metal fluid corrode and anti-oxidation.

Applications of high alumina brick

1. Lower the heat capacity of the furnace

2. Used normally in industry furnaces such as Blast furnace, hot-blast furnace and EAF etc

- Q: What is the difference between corundum and high alumina??

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- Lining 1 yuan to prevent direct damage to the Sindh kiln high temperature flame or air, to protect the kiln carcass; 2, to prevent harmful substances (CO, SO2) erosion of the kiln body; 3, to prevent corrosion, material flow on the kiln body; 4, reduce the kiln temperature, kiln body to prevent oxidation 5, has the function of corrosion; thermal insulation; 6, to improve the coating performance.

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: Which is better, the soft core or the hard core?

- The wire has two kinds of hard core and soft core, the hard core line is only one wire core, and the soft core line has a plurality of wire cores. For the same sectional area, the 7 core is more than the more than 30 core. There is a difference in use. Generally used for DC is the use of hard core line, because of its small line consumption; and for communication, we should use soft core line, but also in order to reduce its line consumption

- Q: How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: The difference between light high alumina brick and heavy aluminum brick

- High aluminum brick is one of the ideal heat insulating material, with high strength, low thermal conductivity, good insulation performance, low price and other characteristics, has been widely used in ceramic tunnel kiln, roller kiln, shuttle kiln, kiln wall, it is also used in various heating furnace coking furnace of iron and steel industry and other thermal equipment heat treatment, lining material, and has broad market prospects.

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Two times mullite refers to the content of aluminum is about 70%, in high temperature sintering, the expansion coefficient is large, the thermal expansion rate is high.

- Q: What causes breakage of refractory bricks?

- There are many factors that lead to the damage of refractory brick, can be divided into: the chemical loss (e.g. salt penetration, redox phenomenon), heat loss (burning, thermal shock), mechanical loss (kiln deformation, thrust, brick masonry quality etc.).

Send your message to us

High Alumina Brick for Furnace - Generality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 10 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches