Heavy Duty Woven Geotextile Fabric Specifications for Needle Punched Nonwoven Geotextile in Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Needle Punched Nonwoven Geotextile for Highway Construction:

1. Water conservancy projec: seawall, dike,river canal engineering;Reservoir reinforcement engineering; Reclamation engineering; Flood control engineering.

2.Highway,railway and airport project: soft foundation reinforcement; Slope protection; Pavement structure layer reflective crack prevention; Drainage system; Greening belt.

3.Electrical engineering : Nuclear infrastructure;Thermal power ash dam project;Hydropower project.

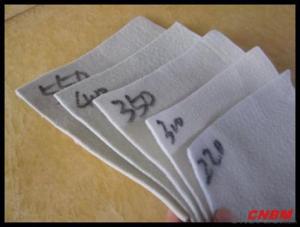

Technical Data Sheet of Needle Punched Nonwoven Geotextile for Highway Construction:

Index Spec.

Article | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

1 | Quality error in unit area,% | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 |

2 | Thickness,mm≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 |

3 | Width error,% | -0.5 | ||||||||||

4 | Breaking strength,KN/m≥ | 4.5 | 7.5 | 10.0 | 12.5 | 15.0 | 17.5 | 20.5 | 22.5 | 25.0 | 30.0 | 40 |

5 | Elongation at break,% | 40~80 | ||||||||||

6 | CBR puncture strength,KN≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 |

7 | Effective aperture 090(095),mm | 0.07~0.2 | ||||||||||

8 | Vertical permeability coefficient , cm/s | K X (10-4-10-3) K=1.0~9.9(K=1.0~9.9) | ||||||||||

9 | Tearing strength,KN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.1 |

FAQ:

What is the main application of Needle Punched Nonwoven Geotextile for Highway Construction?

The main application of our Needle Punched Nonwoven Geotextile for Highway Construction is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for Needle Punched Nonwoven Geotextile for Highway Construction?

One of the largest manufacturer of Needle Punched Nonwoven Geotextile for Highway Construction with advanced equipment, big production capacity and excellent quality.

Over the past decade a greater emphasis has been placed on the development and manufacturing of geosynthetic textiles. While the geosynthetics industry is comparatively new, it has already created products with applications in a wide range of industries including geotechnical, transportation, hydraulic, embankment management, and mining. In many cases, a single geosynthetic textile can solve or improve multiple civil engineering problems simultaneously.

The first example of a geosynthetic textile application is the use of a prefabricated pocket style vertical drain made from a nonwoven filter jacket specialized as a PVD filter material. The purpose of this product was to reduce the time needed for construction by quickly discharging water in the ground which speeds up the soil consolidation process. Overall, it proved to reduce construction time and speed up the consolidation of soft ground in a variety of different situations including road construction, the development of building sites, construction of gas and oil storage facilities, and bank revetment.

The second example of how geosynthetic textiles can provide solutions to civil engineering problems is the polyester woven geotextile mat. It is created from a high tenacity polyester filament which is highly dense. This particular geosynthetic textile has been used to reinforce soft ground and embankments, separate layers of sand and soft ground, prevent the uneven settlement of soft ground, and securing a safe path of travel for heavy equipment across soft ground.

The third example is a silt curtain or fence created by geosynthetic textiles. A silt curtain is installed in the water to prevent the spread of environmentally dangerous contaminants. These contaminants often result from coastal and Riverside construction projects although it can also be used in the event of an open water spill or leak. It has been shown effective at preventing the spread of fine soil and sand induced by construction. It can also prevent the contamination of the nearby seaports and help preserve sea farming and area beaches.

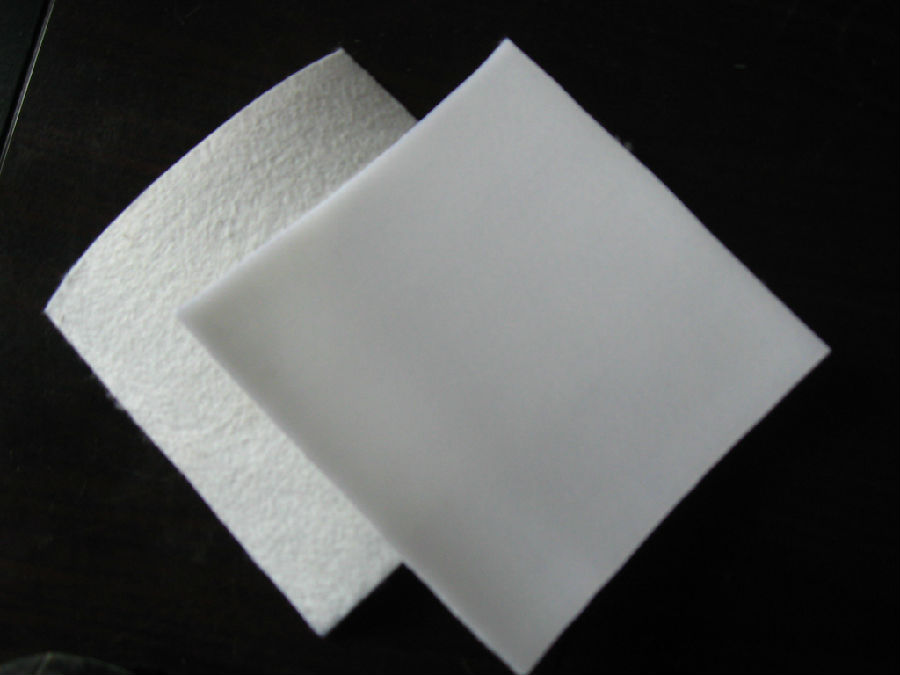

The fourth and final example of geosynthetic textiles assisting with civil engineering problems is the polyester needle punched nonwoven geotextile. It is typically made of continuous filament fiber to promote fast drainage and filtration. It has been used to help prevent landslides, control erosion on banks, protect waterproof layers in landfills, prevent road tracking, and protect waterproof sheets and tunnels.

There is no doubt geosynthetic textiles will continue to play a greater role in finding workable solutions to civil engineering problems across the globe. As their production continues to scale, prices will decrease which will lead to an increase in availability as well as further research and development.

- Q: How do geotextiles help in sediment control?

- Geotextiles help in sediment control by acting as a barrier that traps sediment particles while allowing water to flow through. They prevent erosion by stabilizing the soil, and also help in filtration by retaining sediment and allowing clean water to pass.

- Q: How do geotextiles help with stabilization of railway tracks?

- Geotextiles play a crucial role in stabilizing railway tracks by providing reinforcement and separation between different layers of the track structure. They prevent the mixing of materials, such as subgrade soil and ballast, while also reducing the lateral movement of the ballast. Geotextiles enhance the overall stability and load-bearing capacity of the track, reducing maintenance needs and extending its lifespan.

- Q: Construction scheme of geotextile water filter

- Second, the design: program one: in strict accordance with the requirements of the national standard construction, 5-year warranty 1, in the smooth level of leveling the overall construction brushing JS waterproof latex or polyurethane waterproof coating, the thickness of the national standard 1 standard; Weak parts to do additional layer to strengthen; 2, do 20 ~ 30mm thick waterproof mortar protective layer, divided into two construction, layer waterproof layer of pulp interface; require nano-silicon waterproofing agent and expansion agent compound use. 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice ibid, the wall to do high 1m. Option 2: with reference to national standard requirements simple practice, the warranty period of 1 year 1, the overall construction of coated asbestos asphalt waterproof coating or waterproof cold primer, the thickness of the standard by the national standard 2; special weak parts to do additional layer to strengthen; Outside the protection, requiring the use of sticky or sticky sticky construction; 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice reference program one, the wall to do high 1m.

- Q: Geotextile cloth how many square feet

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: The amount of geotextile drained pipe drape

- According to the two sides agreed by the measurement method, such as by the extension of the package or the expansion of the area can be calculated, you can also agreed to package a tube how much money. Generally calculated by the expansion of the area is more reasonable, because the size of the pipeline.

- Q: Can geotextiles be used in water retention projects?

- Yes, geotextiles can be used in water retention projects. Geotextiles are often used to reinforce soil and prevent erosion, making them suitable for applications such as retaining walls, embankments, and shoreline protection. In water retention projects, geotextiles can be used to create a barrier that traps water and prevents it from seeping into the surrounding soil, thereby increasing water retention.

- Q: What are the factors that affect the strength of geotextiles?

- The strength of geotextiles can be affected by several factors such as the type and quality of materials used, the manufacturing process, the weight and thickness of the geotextile, the presence of any coatings or treatments, and the installation and environmental conditions in which the geotextile is used.

- Q: What are the disadvantages of using geotextiles?

- One disadvantage of using geotextiles is their potential to degrade over time due to exposure to UV rays and other environmental factors. This degradation can reduce their effectiveness and lifespan. Additionally, geotextiles may not be suitable for all soil types or site conditions, and improper installation or selection can result in reduced performance. Lastly, the cost of geotextiles can be relatively high compared to other erosion control or soil stabilization methods, which may limit their affordability for some projects.

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. They are commonly used to separate different soil layers, provide filtration, drainage, and erosion control. Geotextiles can also enhance the stability and strength of the underground structures by providing reinforcement and preventing soil movement.

- Q: How do geotextiles help in reducing the risk of soil liquefaction?

- Geotextiles help in reducing the risk of soil liquefaction by providing reinforcement and stabilizing the soil. They act as a barrier to prevent the movement of water within the soil, reducing the buildup of excess pore water pressure. This pressure is a major factor contributing to soil liquefaction during earthquakes. By promoting drainage and improving soil strength, geotextiles help to mitigate the potential for liquefaction and increase the overall stability of the soil.

Send your message to us

Heavy Duty Woven Geotextile Fabric Specifications for Needle Punched Nonwoven Geotextile in Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords