Heat Resistant Transparent Ceramic Glass 800 Degree 4mm for Glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

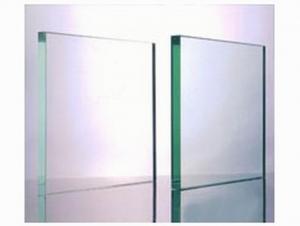

Heat Resistant Transparent Ceramic Glass 800 Degree 4mm for Glass

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

The factory mainly produces

Borosilicate 3.3 heat-resistant glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 3.3 heat-resistant glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

Packing & Delivery

* For small quantities, you can choose DHL or FedEx. It is safe and fast. We have a good rate withthem. Please contact us for

rates.

* Ocean Shipment is economical for big quantity.

* We can also help Custom clearance at destination port and deliver goods to your warehouse or office. And the cost is extra.

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: What is the fire cut off?

- When the fire down the non-burning wall ~ do the role of isolation from the fire

- Q: A1 grade external wall insulation materials which

- At present, only rock wool, glass wool, ceramic fiber, foam glass, inorganic insulation mortar, a1 grade materials generally should not contain organic materials.

- Q: Ventilation duct fan outsourcing fireproof material specifically what

- 8.5.6 Ventilation, air conditioning system piping, etc., should be made of non-burning materials, but contact with corrosive media duct and flexible joints, can be made of refractory materials. 8.5.7 Insulation materials, silencers and adhesives for pipes and equipment shall be non-combustible materials or refractory materials. Through the firewall and deformation of the duct on both sides of the 2.00m should be used within the scope of non-combustion materials and binders. 8.5.8 When the electric heater is installed in the duct, the fan shall be interlocked with the electric heater. Electric heater before and after the 800mm within the duct and through the fire source and other places with easy fire parts of the tube helium bite of the Guobao every double Fu Jing Road, must use non-combustible insulation materials

- Q: In addition to rock wool sandwich panels which plate

- In addition to rock wool sandwich panels which plate...

- Q: Can the interior cement board be used? Is it a fireproof material?

- Would you like to ask if your cement board is in what position? Please explain it in detail? Interior decoration with cement board can be. Is a fireproof material.

- Q: Performance and Difference of Rockwool and Glass Fiber Fireproof Materials

- Rock wool and glass wool fire rating are all A-level rock wool high temperature of 800 degrees glass wool high temperature 450 touch tiger whip mortar Zhuang Huan Biao cloth wave density rock wool relative weight of some glass wool bulk light from the waterproof performance or glass wool better some

- Q: Fire protection requirements for indoor ceiling materials

- In all the interior decoration of the fire design, the ceiling of the fire design in the most important position. This is because the fire is burning up the fire, the ceiling first and directly accept the fire test; the same time, there is a direct impact on the evacuation, will directly constitute a threat to the safety of evacuated personnel. Therefore, in the interior ceiling decoration design, should give full consideration to its fire problem. "Fire protection within the building design fire code" on the different civil buildings of indoor ceiling material fire performance has a detailed requirement. Ceiling (prungroof), refers to the roof of the living environment of the decoration. The ceiling is an important sub-division of the building decoration project. The ceiling has the function of insulation, insulation, sound insulation and sound absorption. It is also a hidden layer of electrical, ventilation and air conditioning, communication and fire prevention, alarm pipeline equipment and so on. The ceiling in the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q: Members colleagues, brother just into the Bank, it is necessary to use the Mylar film, what Mira is the material. Thank you more

- What is the difference between the three? We are more commonly used PC.

- Q: B1 refractory material refractory time long?

- At present, there are five main grades of fire protection: Class A: non-combustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger. In addition, according to different standards, the classification of fire materials are not the same: DIN4102: A1, A2, B1, B2, B3EN-1: A1, A2, B, C, D, E, FB1 fireproof materials, refractory time Look at the specific parts, see the following figure:

- Q: Ul94v-0 refers to the fire level or a material

- 【UL94V-0】 refers to the plastic material of the fire rating (flame retardant grade). Plastic flame retardant grade from HB, V-2, V-1 to V-0 step by step increase: HB: UL94 standard in the bottom of the flame retardant grade. It is required that for samples of 3 to 13 mm thick, the burning rate is less than 40 mm per minute; samples less than 3 mm thick, the burning rate is less than 70 mm per minute; or extinguished before the 100 mm mark. V-2: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. There can be a burning thing falling. V-1: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. Can not have a burning thing falling. V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds. Can not have a burning thing falling. Flammability UL94 grade Flammability UL94 grade is the most widely used combustible performance standard for plastic materials. It is used to evaluate the ability of the material to be extinguished after being ignited. According to the burning speed, burning time, anti-drop ability and whether the beads can burn a variety of judging methods. Each test material can be a lot of values ??depending on color or thickness. When a material of a product is selected, its UL grade shall meet the thickness requirements of the wall part of the plastic part. The UL rating should be reported along with the thickness value, reporting only UL grade without thickness is not enough.

Send your message to us

Heat Resistant Transparent Ceramic Glass 800 Degree 4mm for Glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches