4.0 Heat Tempered Glass Anti-fire Glass Fire Place Fireproof Glass For Fireplaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

4.0 Heat Tempered Glass Anti-fire Glass Fire Place Fireproof Glass For Fireplaces

Fireproof Glass alway use microcrystalline glass, also called ceramic glass is made of a special glass-ceramic, is an extremely heat-resistant, transparent glass ceramic which can be produced in a wide variety of shapes and sizes to meet your specific needs.

Fireproof Glass Advantages:

Our top quality fire-proof glass is widely used for luxury hotel, theater, exhibition hall, airports, gymnasium,hospital,

commercial building and other public building. And all our fire-proof glass has the following features:

(1) Fire-resistance: fire-proof glass can keep down the spread of fire effectively;

(2) Safety: If it is broken, it usually breaks into relatively small pieces, which are less likely to cause serious injury;

(3) High temperature resistance:Fire-proof glass can endure more than 300°C temperature

Bullet-proof glass

Layered with glass,PVB and polycarbonate,the kinetic energy of the bullet is convered into heat by the glass and interlayer.The Bullet-proof glass is widely used for museum artifacts,banks bulletproof,showcase,villa doors and windows etc.

Thickness:3-19mm(can be customized)

Max Size:4800*2440mm

Product Property:Tempered,Laminated

The factory mainly produces

Borosilicate 4.0 fireproof glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

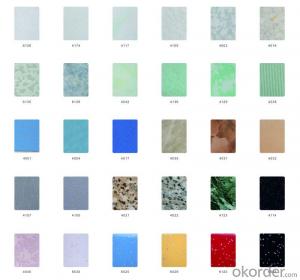

Borosilicate 4.0 fireproof glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

Specification:

Type | fireproof glass |

Thickness can choose | 3-4.5mm |

Glass edging | Flat polish, pencil polish, miter, bevel, O.G. bull nose and etc |

Features | Fireplace glass |

Certificate for factory | ISO 9001 2008, ISO 14001 2004 |

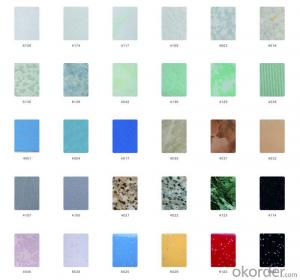

Color | Clear, Ultra Clear, Various Green, Blue, Gray, Brown |

Shape | bent, curved and flat |

Package | Pckage with foam board, cardboard boxes, wooden crates,also can pcak according to cusomer's requirement |

Application | Door for fireplace and stove |

OUR PACKING

Wooden crate, carton box, plastic film, customized, all packing can be fulfilled at Glass.

professional and experienced working stuff, all packing and loading is guaranteed to be strong and seaworthy to reduce the breakage rate to as low as possible.

Package Type:

1)Inter package is paper or plastic between two sheets;

2)Seaworthy wooden crates;

3) Iron belt for consolidation for insulated glass

Company introduction

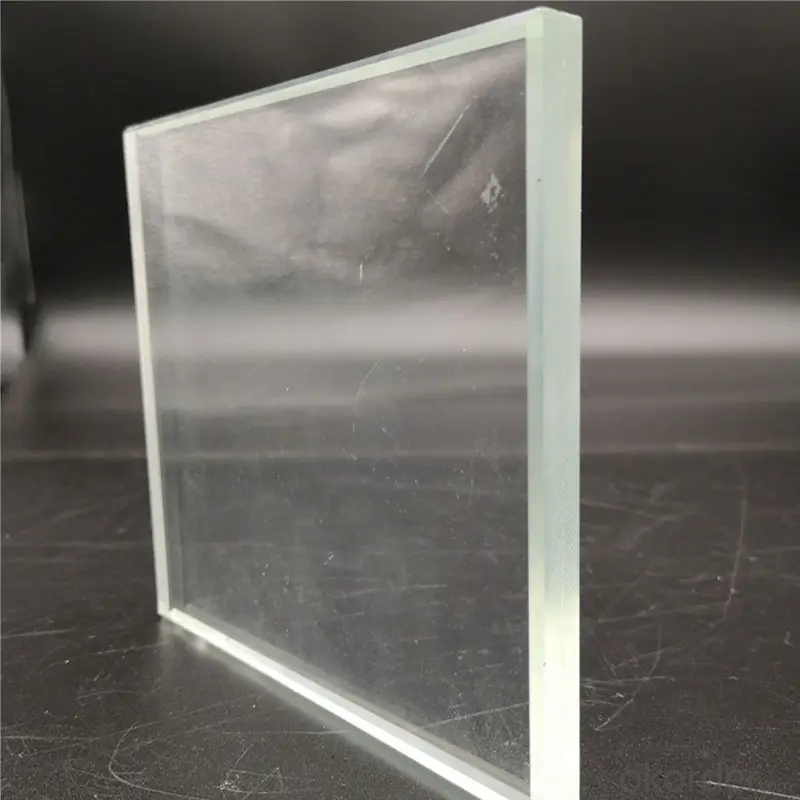

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Are you using fireproof materials for decoration?

- In accordance with national standards, must be matching the standard decorative materials. In the case of non-combustible materials, walls, floors and floors should be made of non-flammable materials to minimize the risk of fire. Keel, cabinets and other wood materials to do fire treatment.

- Q: Is plastic as a fireproof material?

- ABS is not a modified flame retardant ABS material that is ABS fire

- Q: Polyurethane fireproof material really effective?

- From the fire

- Q: Fire doors with fire insulation materials which?

- Perlite fire door core; glass magnesium fire door core

- Q: If you really have this kind of material, please tell me, if you can tell where you can find it really is so much more thanks

- Ice, I told you! By the way tell you can be found in the fridge! you are welcome! Help others for the sake of happiness Well

- Q: Please give a professional to answer ah

- ST cement foam board, foam glass, glass beads and other A-class fire-resistant materials

- Q: What are the building materials, building materials, and interior decoration materials with fire resistance? Can be specific point!

- Each material has its own fire rating, and some hours, there are three hours, so divided into C-class C fireproof material

- Q: Construction of the building when the need to set up a firewall, the most common way is to use solid brick, then do not have this, out of indignation when the fissure when the river with what other can replace, which is better? More

- There are a lot of fireproof materials, but the price is generally higher than ordinary bricks, if you use other fireproof materials can certainly replace, but your cost will increase, so for investors is not worthwhile.

- Q: Fire-resistant coatings are generally water-based or oily

- Oily fire retardant coating: mainly refers to the single toilet teans pear orphan spinach or 200 # gasoline as a solvent fire retardant coating. Film-forming material: resin water-based fire retardant coating: mainly refers to the water as a dilution of the fire retardant coating. Film-forming material: emulsion fire principle Oily and water-based fire retardant coating is the same, but the performance of oily fire retardant paint slightly better than water. Disadvantages: the environment and the human body have some damage thin oil-based fire

- Q: What are the grade I fireproof materials? Which can replace joinery and gypsum board?

- Fireproof materials I know there are rock wool, glass magnesium, our company's production of rock wool purification board, glass magnesium purification board are A-level, there are some materials is also. Hai Zhen purification materials Co., Ltd., you can go to Google search on the corporate website to look at, here can not send the site!

Send your message to us

4.0 Heat Tempered Glass Anti-fire Glass Fire Place Fireproof Glass For Fireplaces

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches