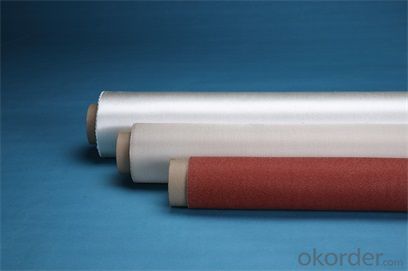

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Silica fiberglass is inorganic fiber that contents more than 96% of SiO2, it's resistant to high temperature, soft point 1700°C, long term service temperature 900 °C, it can work 10 minites at 1450 °C and keeps good state at 1600 °C for 15 seconds. For it's properties of chemical stability, high temperature resistance and ablation resistance, it widely used in aviationand aerospace, metallurgy, chemical, building material and fire fighting industry, etc.

Our factory is the only one that specialized manufacture silica fiberglass in China and has the production line of the whole process from marble making, fiber forming, weaving, and finish. The strength of silica fiberglass made from Na2O-B2O3-SiO2 system glass is 3-5 times higher than that from E glass. The products sold to more than 20 provinces, cities, autonomous regions and exported to foreign countries.

Silica fiberglass products are available in forms of needled mat, fabric, scrim, staple yarn, chopped strand and cord, etc.

Product Properties

1> SiO2>=96%

2> soft point nearly 1700°C, long-time working at 900°C

3> low thermal conductivity

4> good chemical stability

5> good electrical insulation

6> low thermal shrinkage

7> Non-asbestos product without pollution

8> good process performance

Product Uses

High temperature resistant, insulation and sealing material

High temperature ablation resistant material

Fireproof material (for fireproof protective clothe, fireproof curtain, fire blanket)

Dust collecting in media of high temperature gas and filtration in media of high temperature liquid

Filter for molten metal

Distinguisher, insulation material, filtration of automobile and motorcycle

Protective material for welding

Electricity insulation material

- Q: Can glass fiber textiles be used in socks or stockings?

- Certainly, socks or stockings can utilize glass fiber textiles. These textiles, also known as fiberglass fabrics, possess lightweight characteristics, strength, and exceptional thermal insulation properties. They are frequently employed in various industries such as aerospace, automotive, and construction due to their durability and resistance to heat and chemicals. Regarding socks or stockings, glass fiber textiles can offer numerous advantages. Primarily, the thermal insulation properties of glass fibers aid in keeping feet warm during cold weather conditions. This feature proves particularly beneficial for individuals who spend significant time outdoors or in colder environments. Furthermore, the strength and durability of glass fibers render them suitable for incorporation into socks or stockings. They can endure repeated use, stretching, and washing without losing their shape or integrity. Consequently, glass fiber textiles can provide long-lasting and dependable support for the feet. Additionally, glass fiber textiles are commonly utilized in products that necessitate moisture-wicking properties, such as sportswear or outdoor gear. Moisture-wicking fabrics assist in drawing sweat away from the skin, thereby keeping the feet dry and impeding the growth of bacteria and odors. Hence, integrating glass fiber textiles into socks or stockings can enhance overall foot comfort and hygiene. However, it is crucial to note that direct contact with glass fibers can cause skin irritation. To address this concern, manufacturers often encase the glass fibers in a protective coating or blend them with other materials to create a comfortable and safe textile. Consequently, when utilizing glass fiber textiles in socks or stockings, it is imperative to ensure that the fibers undergo proper treatment to minimize any potential discomfort or irritation. In conclusion, glass fiber textiles can indeed be utilized in socks or stockings to provide thermal insulation, durability, and moisture-wicking properties. Nonetheless, it is essential to consider comfort and safety by employing properly treated fibers or blending them with other materials to ensure a pleasant wearing experience.

- Q: Are glass fiber textiles suitable for automotive interiors?

- Yes, glass fiber textiles are suitable for automotive interiors. Glass fiber textiles offer several advantages that make them suitable for use in automotive interiors. Firstly, glass fiber textiles are highly durable and resistant to wear and tear. This makes them ideal for use in the automotive industry where interiors are subjected to regular use and potential damage. They can withstand the rigors of everyday use, including exposure to sunlight, moisture, and temperature variations, without losing their shape or strength. Secondly, glass fiber textiles have excellent heat and sound insulation properties. They can effectively reduce the transmission of heat and noise, enhancing the comfort and driving experience for passengers. This is particularly important in automotive interiors where reducing noise levels and maintaining a comfortable temperature are desired. Furthermore, glass fiber textiles are lightweight, which is a crucial factor in the automotive industry. By using glass fiber textiles in automotive interiors, the overall weight of the vehicle can be reduced, leading to improved fuel efficiency and lower emissions. Additionally, the lightweight nature of glass fiber textiles allows for easier installation and customization of automotive interiors. Moreover, glass fiber textiles offer design flexibility. They can be molded into various shapes and patterns, allowing for creative and unique interior designs. This enables automotive manufacturers to create visually appealing and aesthetically pleasing interiors that enhance the overall look and feel of the vehicle. Lastly, glass fiber textiles are easy to clean and maintain. They are resistant to stains and can be easily wiped clean, making them suitable for automotive interiors that are often exposed to spills and dirt. In conclusion, glass fiber textiles are indeed suitable for automotive interiors due to their durability, heat and sound insulation properties, lightweight nature, design flexibility, and ease of maintenance. Automotive manufacturers can benefit from using glass fiber textiles to create high-quality, comfortable, and visually appealing interiors for their vehicles.

- Q: What are the advantages of using glass fiber textile in composites?

- Glass fiber textiles offer numerous benefits when used in composites: 1. Exceptional strength: Glass fibers possess a remarkable strength-to-weight ratio, making them suitable for applications requiring durability and strength. 2. Enhanced lightweight properties: Glass fiber textiles are lightweight, contributing to a reduction in overall composite material weight. This advantage is particularly valuable in industries like aerospace and automotive, where weight reduction impacts fuel efficiency and performance. 3. Resistance to corrosion: Glass fibers exhibit high resistance to corrosion and do not react with chemicals or moisture. This quality makes them ideal for use in harsh environments, such as marine, chemical, or oil and gas industries, where corrosion resistance is crucial. 4. Excellent electrical insulation: Glass fibers possess superior electrical insulation properties, making them an excellent choice for applications where minimizing electrical conductivity is necessary. Industries like electronics and telecommunications greatly benefit from this feature. 5. Chemical resistance: Glass fibers are resistant to most chemicals, acids, and alkalis, making them suitable for applications involving exposure to harsh chemicals or corrosive substances. 6. Flexibility in design: Glass fiber textiles can be easily molded into complex shapes, enabling the creation of intricate designs and structures. This design flexibility offers engineers and designers greater freedom when developing composite components. 7. Cost-effectiveness: Glass fiber textiles are relatively inexpensive compared to other reinforcement materials, such as carbon fiber. This affordability makes them a cost-effective option for applications requiring high strength and durability, even in the presence of budget constraints. Overall, the advantages of using glass fiber textiles in composites encompass their high strength, lightweight nature, corrosion resistance, electrical insulation properties, chemical resistance, design flexibility, and cost-effectiveness. These properties have established glass fiber textiles as a preferred choice within various industries, including construction, automotive, aerospace, and electronics.

- Q: Can glass fiber textiles be used in body armor or protective gear?

- Glass fiber textiles, also known as fiberglass, possess exceptional qualities that render them appropriate for utilization in body armor and protective gear. Primarily, glass fiber textiles exhibit a high strength-to-weight ratio, signifying that they are lightweight yet sturdy, rendering them optimal for incorporation in body armor. Consequently, wearers can maintain optimal agility and flexibility while remaining safeguarded. In addition, glass fiber textiles exhibit remarkable impact resistance. They can efficiently absorb and distribute the force of impacts, an indispensable characteristic in averting injuries caused by blunt force trauma. Thus, they prove effective in shielding against projectiles or other forms of impact. Moreover, glass fiber textiles display commendable chemical resistance, rendering them impervious to diverse chemicals and corrosive agents. This feature assumes great importance in scenarios where the protective equipment may encounter hazardous substances. Furthermore, glass fiber textiles possess excellent thermal insulation properties. They can provide heat resistance, thereby making them suitable for deployment in protective gear necessitating thermal protection, for instance, firefighting suits. Overall, the amalgamation of strength, impact resistance, chemical resistance, and thermal insulation in glass fiber textiles renders them aptly suited for employment in body armor and protective gear.

- Q: Are glass fiber textiles resistant to moisture or water?

- Glass fiber textiles possess resistance against moisture and water. They are composed of inorganic substances like silica, which prevents the absorption of water or moisture. This innate moisture resistance renders glass fiber textiles exceptionally suitable for areas prone to water or high humidity, such as bathrooms, kitchens, or outdoor settings. Furthermore, glass fiber textiles retain their integrity and durability in wet conditions without rotting or degrading, ensuring their longevity.

- Q: What are the properties of glass fiber textiles?

- Glass fiber textiles are a type of textile material that is made from fine strands of glass fibers. These fibers are typically woven together to create a fabric that has several unique properties. One of the main properties of glass fiber textiles is their high strength-to-weight ratio. Despite being lightweight, these textiles are incredibly strong and can withstand a great deal of tension and pressure. This makes them suitable for a wide range of applications where strength is required, such as in the construction industry for reinforcement purposes. Glass fiber textiles also exhibit excellent heat resistance. They have a high melting point and can withstand high temperatures without losing their structural integrity. This property makes them ideal for use in applications that involve exposure to heat or fire, such as insulation materials for buildings or protective clothing for firefighters. Furthermore, glass fiber textiles are highly resistant to chemical corrosion. They are not easily affected by acids, alkalis, or other corrosive substances, which makes them suitable for use in environments where chemical exposure is a concern. This property also makes them a preferred choice for manufacturing certain types of filters and chemical-resistant clothing. In addition to their strength, heat resistance, and chemical resistance, glass fiber textiles are also known for their excellent electrical insulation properties. They have a low electrical conductivity, which means they do not conduct electricity easily. This makes them useful in applications where electrical insulation is required, such as in the production of electrical wires and cables. Lastly, glass fiber textiles are non-combustible. They do not burn easily and do not contribute to the spread of fire. This property makes them highly desirable for use in fire-resistant materials, such as curtains, upholstery, and protective clothing. Overall, glass fiber textiles possess a unique combination of properties, including high strength, heat resistance, chemical resistance, electrical insulation, and non-combustibility. These properties make them versatile and suitable for various industries and applications, ranging from construction and insulation to electrical and protective clothing.

- Q: Are glass fiber textiles suitable for outdoor applications?

- Yes, glass fiber textiles are suitable for outdoor applications. Glass fiber textiles are known for their excellent durability and resistance to harsh weather conditions. They are highly resistant to UV radiation, moisture, and temperature fluctuations, making them ideal for outdoor use. Glass fiber textiles can be used in various applications such as outdoor furniture, awnings, canopies, and protective covers. They provide excellent strength and stability, allowing them to withstand heavy wind loads and other external forces. Additionally, glass fiber textiles are lightweight and easy to handle, making them a practical choice for outdoor applications.

- Q: Can glass fiber textile be used in tents and awnings?

- Certainly! Tents and awnings can indeed utilize glass fiber textile. This material, being both lightweight and durable, possesses exceptional strength and resilience against severe weather conditions. Moreover, it displays resistance to UV rays, rendering it ideal for outdoor purposes. Often employed as reinforcement in tent and awning construction, glass fiber textiles enhance stability and structural integrity, enabling these shelters to withstand strong winds and heavy rain. In addition, they are effortless to clean and maintain, boasting a lengthy lifespan, which accounts for their popularity in outdoor shelters.

- Q: Are glass fiber textiles resistant to wear or abrasion from friction?

- Yes, glass fiber textiles are generally resistant to wear and abrasion from friction. Glass fibers are known for their high tensile strength and durability, making them highly resistant to abrasion. The fibers are tightly woven or knitted together, creating a strong and dense fabric that can withstand repeated rubbing or friction without showing signs of wear. Additionally, glass fiber textiles are often treated with protective coatings or finishes that further enhance their resistance to wear, ensuring their longevity and durability in various applications.

- Q: How do glass fiber textiles affect the flexibility or stiffness of fabrics?

- Glass fiber textiles can significantly impact the flexibility or stiffness of fabrics. When incorporated into fabrics, glass fibers add strength and rigidity, making the fabric stiffer and less flexible. This is particularly useful in applications where structural support is required, such as in reinforced composites or industrial fabrics. However, the extent of the effect on flexibility or stiffness depends on the concentration and arrangement of glass fibers within the fabric.

Send your message to us

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords