Heat Insulation Refractory Aerogel Thermal Insulation Felt

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description

Aerogel Insulation Felts

Using special nanotechnology, It combines a silica aerogel with reinforcing fibers to deliver very low thermal conductivity, low density and good flexibility in an environmentally safe product. It provides excellent properties of waterproof, sound absorption and shock absorption. It is an alternative to the common, environment unfriendly, inferior insulation products, such as PU, asbestos insulation felt, silicate fibers, etc.

2.Specifications

1.Superior Thermal Performance

2.Long service life

3.Environmentally Safe

4.Sound resistance

3. Advantages

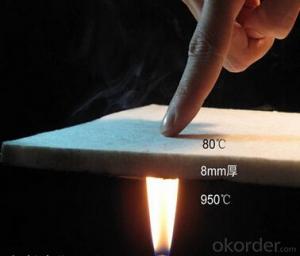

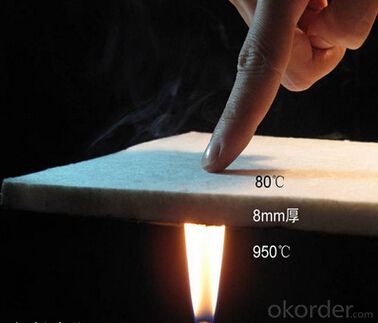

(1).Superior Thermal Performance

The maximum use temperature is 1000℃,Its thermal conductivity is 1/3~1/5 of common insulators, helping reduce heat loss and optimizing space utility.

(2). Long service life

Unlike other traditional insulation materials, aerogel ’s three- dimensional, structure inhibits sintering warpage, and particles stack which may occur under hot temperature for long time. Therefore, aerogel insulation has long service life.

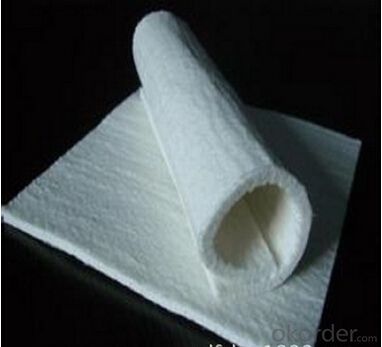

(3). Physically Robust:

It has flexibility and high tensile strength, resisting stretching and stress from linear contraction when temperature changes.

(4). Environmentally Safe:

Composed of inorganic materials, it contains no hazard. Stripping little chloridionm will cause no corrosion to the equipments and pipes.

Low and ultra-low temperature equipment and piping applications

Petrochemical, power equipment applications

(5). Easy to Install

Extremely low density (200kg/m3) contributes to easy-to-cut and easy-to-install.

4. Technical Standard

Property | Unit | Techicial Standard | |

(refractoriness) | ---- | A Grade | |

(Density) | kg/m3 | <220< span=""> | |

(Lyophobic) | % | >99 | |

Thermal Conductivity | 25℃ | W/(m·K) | ≤0.023 |

70℃ | ≤0.029 | ||

200℃ | ≤0.036 | ||

300℃ | ≤0.045 | ||

400℃ | ≤0.056 | ||

5. Application

Oil pipe, steam pipe, refrigerator interlining, oil tank, central airconditioning pipe, chemical pipe with the requirement of fire resistance, vehicle thermal insulation, national defence, military industry, heat supply pipelines in city insulation, biological medicine pipes and equipment and so on.

- Q: Is the glass wool sound insulating? How good is it?

- Glass wool glass fiber is a kind of inorganic fiber in the category of glass fiber.The glass wool is of corrosion resistance, chemical stability, low thermal conductivity, low bulk density, thermal insulation and good sound-absorbing property. Besides, the chemical composition of glass wool is glass.

- Q: If the glass wool is used for thermal insulation outside seamless steel tube, should the pipe be rust-proof and sprayed paint?

- Rust-proof treatment must be done. Without special requirements, you can use epoxy rustproof paint for basic protection. For high demands, you should use zinc anti-corrosion paint.

- Q: Behind the wall at the head of bedroom is an elevator, but how can indulate sound? Waht do you think if install silicic acid board of 12 centimeters plus glass wool and splint fo 9 centimeters and then nail soft package background in the rear?

- 1, It is advisable to buy another house because this case autually attirbutes to serious defect of the housing design. 2, You can try to change the bed to the opposite direction. 3, If adopted sound proof wall, you can refer to the pictures I offered. 4, Using board of 9cm can effectivley reduce low frequency noise of elevator.

- Q: How to convert thickness if the heat insulation effects of glass wool board and rubber and plastic board is the same?

- Calculated in accordance with the respective heat insulation layers

- Q: What is the function of glass wool foil?

- Glass wool is one kind of the glass fiber and it is a man-made inorganic fiber. Glass is made by melting such raw materials as quartz sand, limestone, dolomite and other natural ore with some chemical materials like pure alkali and sodium borate. In the molten state, the glass is thrown into fine fibers in the shape of floc by the with external force. These fibres vertically interwine and show many small gaps. These gaps can be regarded as air void. Thus, glass wool can be regarded as porous materials and it is of good insulation and sound absorption performance.

- Q: How to fix centrifugal glass wool felt for steel structure?

- Self-tapping screw

- Q: Who can tell me about the unit weight of glass wool board?

- Glass wool has a good sound absorption performance in the high-frequency sound. The main factors affecting the centrifugal glass wool' sound absorption performance are thickness, density and air flow resistance, etc. Density is the weight per cubic meter of materials. 1. with the increase of thickness, the low frequency sound absorption coefficient significantly increases, but there is little change in the high frequency (high frequency absorption is always larger). 2. thickness is the same, the unit weight increases, the low frequency sound absorption coefficient also increases; but when the unit weight increases to a certain extent, the material becomes dense, the flow resistance is greater than the optimum flow resistance, sound absorption coefficient decreases.

- Q: What are the differences between glass wool and rock wool in terms of thermal insulation?

- If the temperature is higher than 300 degrees, the rock wool boards are better. The operation life of glass wool at high temperature is short, and the price of which is higher than that of rock wool. Galvanized board can be used as protective layer for its long operation life but it rusts easily and is not so beautiful. The aluminium plate has a short operation life and it damages and deforms easily.

- Q: What is the highest temperature that the fireproof glass?cotton can resist?

- It is certain that A level is the highest. A level indicates that it is non-combustible. Level B indicates that it is fire?retardant. Rock wool can resist 800 ℃ and glass wool can resist 450 ℃. The hest perservation effect of matetials of B level is relatively better.

Send your message to us

Heat Insulation Refractory Aerogel Thermal Insulation Felt

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords