Heat Exchanger Stainless Steel Pipe TP304 ASTM A213

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Heat Exchanger Stainless Steel Pipe TP304 ASTM A213

Heat Exchanger Stainless Steel Pipe TP304 ASTM A213 is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, Heat Exchanger Stainless Steel Pipe TP304 ASTM A213 are perceived to be stronger and more reliable. Historically Heat Exchanger Stainless Steel Pipe TP304 ASTM A213 was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Heat Exchanger Stainless Steel Pipe TP304 ASTM A213

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Heat Exchanger Stainless Steel Pipe TP304 ASTM A213 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Heat Exchanger Stainless Steel Pipe TP304 ASTM A213

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

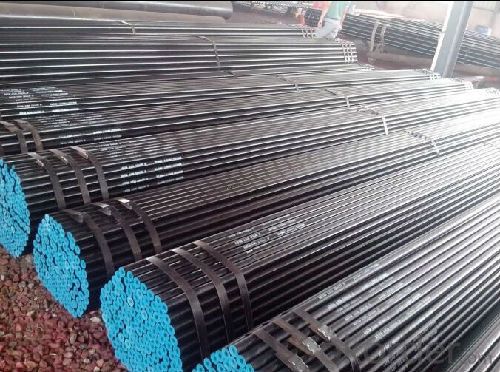

6、Seamless Pipe ASTM A106/53 Images:

- Q: Stainless steel pipe welding interface leakage, how can we not leak?

- Welding process should be completely observed, especially between layers, and each layer shall be welded until the temperature is controlled;

- Q: Can stainless steel pipes be used for exhaust systems?

- Indeed, exhaust systems can utilize stainless steel pipes. Stainless steel, renowned for its exceptional resistance to both corrosion and heat, is a favored material for exhaust systems. It possesses the ability to withstand the severe temperatures and harsh circumstances to which exhaust systems are exposed, rendering it an enduring and long-lasting alternative. An added benefit of stainless steel pipes is their lightweight nature, which can enhance the performance of the exhaust system. Furthermore, stainless steel pipes can be effortlessly manipulated and molded, allowing for tailor-made adaptations to suit various vehicle models and configurations. All in all, stainless steel pipes present a dependable choice for exhaust systems, guaranteeing outstanding performance and longevity.

- Q: Are stainless steel pipes suitable for high-temperature steam?

- Certainly, stainless steel pipes are well-suited for the transportation of high-temperature steam. Renowned for its exceptional resistance to both heat and corrosion, stainless steel proves to be an optimal choice for applications involving elevated temperatures and steam. The substantial presence of chromium and nickel in stainless steel aids in its ability to endure the corrosive impact of steam, thereby averting oxidation and preserving its structural integrity. Furthermore, stainless steel pipes boast remarkable strength and durability, guaranteeing their capacity to withstand the pressure and strain induced by high-temperature steam. In summary, stainless steel pipes provide a dependable and enduring solution for the conveyance of high-temperature steam across various industries, including power generation, chemical processing, and oil and gas.

- Q: How are stainless steel pipes joined or connected?

- Stainless steel pipes are typically joined or connected through various methods depending on the specific application and requirements. One common method is welding, where the pipes are fused together using heat to create a strong and durable connection. This can be done through various welding techniques, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. Another method is through threading, where the ends of the pipes are threaded and then screwed together using pipe fittings. This is a popular method for smaller diameter pipes or when disassembly is required. Additionally, stainless steel pipes can also be connected using compression fittings, which involve using a compression ring or ferrule to create a tight seal between the pipes. This method is often used for connecting pipes with larger diameters or in situations where frequent disassembly is necessary. Overall, the method of joining or connecting stainless steel pipes depends on the specific requirements of the project, including factors such as pipe size, pressure, temperature, and the need for disassembly.

- Q: How do stainless steel pipes compare to ductile iron pipes?

- When it comes to comparing stainless steel pipes to ductile iron pipes, there are several factors that need to be taken into consideration. To begin with, stainless steel pipes possess a greater resistance to corrosion in comparison to ductile iron pipes. This is attributed to the presence of chromium in stainless steel, which creates a protective layer on the pipe's surface, preventing rust and corrosion. Conversely, ductile iron pipes are more susceptible to corrosion and may require additional coatings or linings for protection. Moreover, stainless steel pipes exhibit a higher strength-to-weight ratio than ductile iron pipes. This implies that stainless steel pipes can withstand higher pressure and have a longer lifespan, thereby making them more durable and dependable. While ductile iron pipes are also strong, they are generally heavier, which can pose challenges during installation. Another crucial aspect to consider is the cost. Typically, stainless steel pipes tend to be more expensive than ductile iron pipes, primarily due to the higher cost of raw materials and manufacturing processes involved. However, the longer lifespan and reduced maintenance requirements of stainless steel pipes can offset this initial cost, making them a cost-effective choice in the long term. In terms of versatility, stainless steel pipes offer greater flexibility in terms of design and application. They can be easily welded, bent, and fabricated to meet specific requirements. In contrast, ductile iron pipes have limited flexibility and are mainly used for underground water and sewage systems. Overall, both stainless steel and ductile iron pipes have their own set of advantages and disadvantages. The decision between the two will depend on factors such as the specific application, budget, and desired lifespan.

- Q: What is the difference between 409 and 316 stainless steel pipes?

- The composition and intended use are what differentiate 409 and 316 stainless steel pipes. 409 stainless steel is categorized as ferritic stainless steel, containing more chromium but less nickel than 316 stainless steel. This means that 409 stainless steel is less resistant to corrosion and oxidation. However, it is still suitable for applications that require moderate levels of corrosion resistance, such as automotive exhaust systems and heat exchangers. On the contrary, 316 stainless steel is classified as austenitic stainless steel, with higher amounts of both chromium and nickel. Because of its composition, it provides excellent corrosion resistance, even in demanding environments. Therefore, it is commonly used in applications where superior resistance to corrosion is necessary, such as marine environments, chemical processing plants, and medical equipment. To summarize, the main distinctions between 409 and 316 stainless steel pipes are their composition and corrosion resistance. 409 stainless steel is appropriate for applications with moderate levels of corrosion resistance, while 316 stainless steel is the preferred choice for applications that demand superior corrosion resistance in harsh environments.

- Q: Disadvantages of stainless steel tubes

- A more traditional but more expensive pipeline material, durable and more convenient construction. Copper is the first choice in many imported bathroom products. Price is the most important reason for its use, in addition, copper corrosion is also a factor.

- Q: What is the maximum pressure rating for stainless steel pipe fittings?

- There are several factors that contribute to the maximum pressure rating of stainless steel pipe fittings, including the material grade, size, and temperature. In general, stainless steel pipe fittings have the ability to handle high-pressure applications due to their strength and resistance to corrosion. The pressure rating of these fittings can vary greatly, ranging from 150 psi to as high as 10,000 psi, depending on the specific fitting and its intended use. To determine the maximum pressure rating for a particular stainless steel pipe fitting, it is important to refer to the manufacturer's documentation or industry standards such as ASME B16.11 or ASME B16.9. Additionally, when working with high-pressure systems, other factors such as the sealing method, compatibility with the conveyed fluid, and any necessary safety precautions must be taken into consideration.

- Q: The difference between galvanized steel pipe and stainless steel pipe

- Stainless steel pipe is a kind of hollow long strip round steel, mainly used in petroleum, chemical, medical, food, light industry, machinery, instrument and other industrial pipeline and mechanical structure parts. In addition, the bending and torsional strength of the same weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: How about stainless steel 2520 and 316?

- 2520 stainless steel (310S) austenitic chromium nickel stainless steel has good oxidation resistance, corrosion resistance, because of higher content of chromium and nickel content, which has high temperature creep strength, can continuously work under high temperature, good heat resistance. For Ni (Ni), chromium (Cr) content is high, with good oxidation resistance, corrosion resistance, acid and salt, high temperature performance, high temperature resistant steel dedicated to the manufacture of electric furnace tube and so on, increase the amount of carbon austenitic stainless steel, due to the solid solution strengthening effect to the strength improved, chemical composition characteristics of austenitic stainless steel is chrome, nickel based addition of molybdenum and tungsten, niobium and titanium elements, as its face centered cubic structure, and strength and high creep strength at high temperature.

Send your message to us

Heat Exchanger Stainless Steel Pipe TP304 ASTM A213

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords