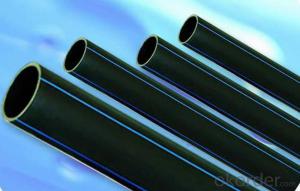

HDPE Pipe PE100 Plastic Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

HDPE pipe

1.Model: DN16mm-DN1200mm

2.Material: PE80, PE100

3.Press level: 0.4MPa-1.6MPa

Features:

Model: DN16mm-DN1200mm

Material: PE80, PE100

Press level: 0.4MPa-1.6MPa

Color: black, with blue strip

Executive standard: ISO4427 EN12201 ASTMF714 AS4130 GB/T13663

Length: 4m,6m and 12m, or as your request

HDPE pipe Performance and Features:

1. Environmental Material.

HDPE is a kind of no-toxic, tasteless and unharmful chemical material, and HDPE PIPE, inherits those typical features nicely.

2. Good Flexibility.

When it is used in dredging pipe, the rubber flexible connectors can be saved because of its good flexibility.

3. Low Hydraulic Resistance.

The smooth inner wall make the water transportation capacity improve more than 30% under the same condition.

4. No Leakage.

The technics of hot-fusion and electric-fusion make sure the the strength of welding point is stronger than the body pipe itself.

5. High abrasion performance.

Its wear resistance is 4 times as the steel pipe.

6. Anti-corrosion and crack growth resistance.

7. Long lifetime durable in use.

50 years at least.

8. Economy

Low delivery, installation and maintenance cost.

HDPE water supply pipe application

1. Water pipe network system for civil engineering.

2. Urban and rural drinking water pipeline.

3. Agricultural irrigation pipe.

4. Other industries related to liquid transportation, especially for corrosive liquid.

- Q: How do plastic tubes compare to ABS tubes in terms of impact resistance?

- Plastic tubes generally have lower impact resistance compared to ABS tubes. ABS (Acrylonitrile Butadiene Styrene) is known for its exceptional impact resistance, making it a preferred choice in applications where durability and resistance to impacts are crucial.

- Q: Do plastic tubes have any limitations in terms of flexibility or rigidity?

- Yes, plastic tubes do have limitations in terms of flexibility and rigidity. While some plastic tubes can be quite flexible, allowing for easy bending and manipulation, others may be more rigid and less flexible. The level of flexibility or rigidity depends on the type of plastic used and the manufacturing process. Additionally, plastic tubes may have a maximum bending radius beyond which they may deform or break. Therefore, it is important to consider these limitations when selecting plastic tubes for specific applications.

- Q: How can I make plastic pipes harden quickly?

- You say this kind of plastic pipe is PVC tube, it will harden in cold weather, and it will harden for a long time. Because of the hardening of the temperature, do not worry, the temperature will rise back, will return to normal, because this is the characteristics of PVC plastic. With a long hardening, this is the aging phenomenon, due to ultraviolet radiation and oxidation caused by irreversible reactions.

- Q: my hamster is stuck in his tube i dont know how to get him out!

- ok so get a hammer if its one of those hard plastic tubes, and then smash an end wear the hamster is not near so u dont hurt him and then once it breacks, you can make the crack go all the way to the other side and then you can take the tube inhalf and out comes ur hamsteR:] also you can try putting some olive oil around him and try pushing him out with something, dont worry, hamsters are always getting cought i n tight places, thats what their boddy is for

- Q: Are plastic tubes suitable for use in the automotive fuel system?

- No, plastic tubes are not suitable for use in the automotive fuel system as they are not able to withstand the high pressures and temperatures associated with fuel delivery.

- Q: Can plastic tubes be used for swimming pool covers?

- Yes, plastic tubes can be used for swimming pool covers. These tubes are often used to support the cover and keep it in place, preventing debris from entering the pool.

- Q: Are plastic tubes suitable for use with corrosive substances?

- No, plastic tubes are not suitable for use with corrosive substances as they can degrade and react with the corrosive material, potentially causing leaks and contamination.

- Q: How do plastic tubes compare to polyvinyl chloride (PVC) tubes in terms of durability?

- Plastic tubes and polyvinyl chloride (PVC) tubes are essentially the same thing. PVC is a type of plastic that is commonly used to manufacture tubes due to its durability and resistance to chemicals and weathering. Therefore, there is no significant difference between plastic tubes and PVC tubes in terms of durability.

- Q: What are the different end closures available for plastic tubes?

- There are several different end closures available for plastic tubes, including screw-on caps, flip-top caps, snap-on caps, push-pull caps, and dispensing pumps. These closures provide various functionalities and convenience depending on the intended use of the plastic tube.

- Q: How are plastic tubes filled with adhesives or sealants?

- Plastic tubes are typically filled with adhesives or sealants through a process called tube filling. This involves using specialized equipment that dispenses the adhesive or sealant into the tube, while ensuring proper measurement and uniformity. The tube is filled by either manual or automated processes, where the adhesive or sealant is carefully transferred into the tube's opening using a nozzle or syringe. Once filled, the tube is sealed to prevent any leakage or drying out of the adhesive or sealant.

Send your message to us

HDPE Pipe PE100 Plastic Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords