HCSA Cement 92.5MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 10000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HCSA BINDER is manufactured under a strict quality assurance systems GB/T 19001-2000 and GB/T 24001-1996 which accommodates the

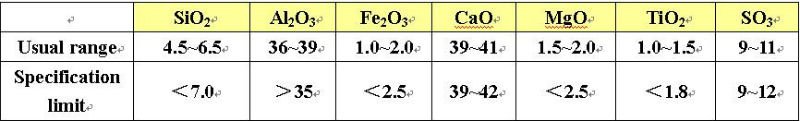

Chemical Analysis

The chemical analysis of HCSA BINDER has been determined according to the following:

GB/T 176-1996 Methods of chemical analysis for cement

Main constituents (%)

Fineness

Specific Surface Area: according to standard GB/T 8074-1987

Usual range: 360~430 m2/kg

Specification limit: >360 m2/kg

Reactivity with Portland cement

HCSA BINDER may be used in combination with other mineral products, for example PORTLAND cement, calcium sulphates and fillers, or with organics such as polymers in latex form or in redispersible form.

Depending on the type of mixes and technology employed, HCSA BINDER can be used to obtain and control various properties.

The behaviour of PORTLAND cement is vary variable. In general, acceleration of set increases progressly with the addition of HCSA BINDER. The amount of HCSA BINDER needed to obtain a specific setting time varies considerably depending on the origin of the PORTLAND cement and performance can be modified with the use of additives.

The strength development of HCSA BINDER/PORTLAND cement and/or Calcium Sulphates depend on the nature of the PORTLAND cement and/or Calcium Sulphates used. In general these mixes will develop mechanical strength at a very early stage (several hours). With some type of PORTLAND cements and in formulated products containing additives which control the setting and hydration, the long term properties is similar to those of the original PORTLAND cement, however it is necessary to check the behaviour of each PORTLAND cement used.

The characteristics of PORTLAND cement to be considered are:

1. C3A content

2. Mineral admixture type and content

3. Type of Calcium Sulphate used

Additives will also influence the properties of these mixes:

1. Setting time

2. Rheology

3. Mechanical performance

These properties are applied to obtain a wide range of products:

1. Fast setting cements

2. Rapid hardening mortars

3. Tile adhesives

4. Self-leveling compounds

5. Non-shrink grouts

6. Water stopping mortars

7. etc.

With a careful selection of the constituents (OPC, calcium sulphates, additives), it is possible to create mixes with a range of different hydraulic properties:

1. Adjustable setting time

2. Rheology adapted to the application

3. High early strength

4. High long term strength

5. Shrinkage compensation

Use of Additives

HCSA BINDER may be used in combination with chemical additives such as:

1. polymers, either in latex form or redispersible powder form

2. defoamers

3. retarders

4. accelerators

5. plasticizers/superplasticizers

6. rheology modifiers

7. fibers

- Q: please help...

- IT IS VERY HARM FULL

- Q: I'm trying to replace the water supply turn valve under my bathroom sink. Whoever installed it put a yellow cement (plumbers cement?) on the threads between the nuts and the body of the valve. Is there a solvent that will dissolve the cement? All I can tell you about the cement is that it's yellowish in color. Here's a picture of the type of valve I have.

- Yes, it is a type of pipe dope (thread sealer). There are joint and gasket sealers sold world-wide. Hercules, Tap-con, Dope Pro and etc. all have sold this type of product. The older ones ALWAYS dried to a cement like seal. There is no solvent available for this issue. Unfortunately, if an old version was used, you only have 2 options available. 1. You can use your torch to heat and loosen the product form the valve. The real problem here is that if you are using the type of valve you posted in the picture, you run the great risk of permanently ruining the valve anyway. 2. Simply cut behind the valve and solder in a new one. Use the tape thread sealer and off you go. This is BY FAR the best option. Write to me if you have any questions. I'll be happy to help anytime. EDIT: Bill, Here's the issue. The pipe dope usually remains somewhat flexible for a long time. However, penetrating oil will not do the job. If you have a Monkey wrench, vice grip or a slip wrench (aka Channel) you have a good chance. You can heat the joint with a hair dryer. This may soften it enough. Hold the valve firm, with one of the above in one hand, and loosen the nut with the other. Vice grips work best to hold the valve steady. There are other options if this fails to work for you. One is to cut the feed line, and splice a new one on (using compresion fittings or a pipe splice). The best option is to turn the water off to the valve, cut the pipe below/behind it, and solder a new one on. If you are worried about soldering, buy a tool and die thread maker (inexpensive), create new thread and screw a new valve into place. If you are inexperienced at this, the soldering option is best. Vote for me, and feel free to write again should you have any questions. The return mail option did not work.

- Q: What is the difference between lime and cement in building materials?

- What is the difference between lime and cement in building materials?

- Q: The factory was established this month, not yet officially produced, is now renovated workshop. More

- Can be divided into three categories: machine materials, inorganic materials (metal, non-metallic), composite materials.

- Q: My question is based on Science article about ship worms. According to article ship worms are in clam family.

- I have never heard of any animal that can digest cement. Most mollusks that have shells gets the raw materials (like calcium) in a dissolved state in the water. If you would put a clam in pure water without these dissolved minerals they could not make their shell. And very few animals can digest cellulose because they do not have enzymes that can break the bonds between glucose units in cellulose. Certain bacteria can produce such enzymes and therefore they can digest cellulose or wood. Such bacteria can be found in the digestive system of termites. They digest the wood for the termites. I imagine some similar situation exists in ship worms.

- Q: I need to glue a small plastic piece to another plastic piece, will the cement work? What are the steps in gluing and making sure the glue holds?

- where did you buy the barge cement glue here in singapore?

- Q: What is the total weight of a cubic meter of the mix? what part is cement? stone?sand? add these fractional amounts.what is the result? 420+150+120=690Kg, total 690 -420 used what part =n 420/690divided by 10/10=42/69divided by3/3=14/23 cement, how do you figure out stone and sand?

- 150 Kg To Stone

- Q: What do I do? Is it harmful?

- Take it to a emergency hospital. Yes, rubber cement being swallowed would be harmful to both humans or other mammals. I suggest you first call a vet to make sure, and then do as they instruct, even if it would be just as the following said take it to the emergency hospital. I suggest calling the vet first, just in case.

- Q: It doesn't have 2 b painted it just has 2 b cement and in Ohio

- We have those places with cement lawn ornaments everywhere here in Indiana. I dont know what part of Ohio you are in, but here are a bunch of places in Ohiop that sell concrete lawn ornaments. They should have the geese. Im sure it is a popular item. Dont forget to buy clothes for your goose!

- Q: i want to practice track on the streets and i want to break in track shoes with spikes

- No! that is a TERRIBLE idea! it will flat out ruin your spikes and kill your legs

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Mid East; Eastern Asia; Western Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang, Jingtang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Japanese, Russian, Korean |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

HCSA Cement 92.5MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 10000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords