Hanes Geotextiles Wooden Silt Fence/Polypropylene Woven Fabric 100gram

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Silt Fence Description:

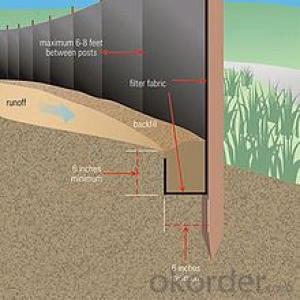

A silt fence, also referred to as a filter fence, is a structure composed primarily of geotechnical fabric and that is used as a form of sediment control.These temporary barriers are relatively low in cost, especially when compared to the damages they can prevent. They keep loose soils from traveling into local bodies of water and they also minimize the impact that various forms of development can have on surrounding wildlife.

2. Silt Fence Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

3.. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the different installation methods for geotextiles?

- There are several different installation methods for geotextiles, including direct placement, overlay, and confinement. Direct placement involves simply placing the geotextile directly on the ground or subgrade. Overlay installation involves placing the geotextile on top of another material, such as soil or aggregate, to provide separation or filtration. Confinement installation involves enclosing the geotextile within a structure, such as a retaining wall or gabion, to provide reinforcement or erosion control. The choice of installation method depends on the specific application and desired functionality of the geotextile.

- Q: What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include the material composition, UV exposure, chemical resistance, physical properties, installation and maintenance practices, and environmental conditions such as temperature and moisture levels.

- Q: How do geotextiles help in preventing soil contamination from chemicals?

- Geotextiles act as a protective barrier between the soil and chemicals by preventing their infiltration into the ground. They effectively filter and separate contaminants, allowing water to flow through while retaining harmful substances. This helps in minimizing soil contamination and preserving its quality.

- Q: Application Index of Geotextile Geotextile Expressway

- Too professional, and find a happy manufacturers it

- Q: Filter geotextile, permeable geotextile, seepage geotextile What is the difference?

- The above three products are a product. But is divided into polypropylene staple acupuncture geotextile, polyester staple acupuncture geotextile, filament geotextile. Three categories. Play a major role is good permeability, filtration, isolation performance, construction convenience.

- Q: How do geotextiles help with soil stabilization in geocell applications?

- Geotextiles aid in soil stabilization in geocell applications by providing a barrier between the soil and the geocell structure. This helps to prevent soil erosion, promote proper drainage, and increase the overall strength and stability of the soil.

- Q: How do geotextiles help with soil stabilization in slope stabilization projects?

- Geotextiles assist in soil stabilization in slope stabilization projects by providing reinforcement and erosion control. These specialized fabrics are placed within the soil structure to enhance its strength, prevent erosion, and promote proper water drainage. By distributing loads and reducing soil movement, geotextiles help maintain the stability of slopes and prevent potential landslides or soil erosion.

- Q: Geotechnical deployment of aging detection of what indicators

- Material anti-aging performance testing, if the reality to consider, for too long, are generally used in the laboratory to accelerate the aging approach to consider. Aging the concept of aging is a big concept. Refers to the material in the external environment under the influence of time changes. Environmental effects are multifaceted, the role of light, the role of temperature, a chemical role, the role of micro-organisms and so on. Now generally referred to as aging, refers to the light aging. Light aging, refers to the material in a certain light exposure after a certain period of time after the performance of the material changes. The most commonly used indicator for photoaging is the strength retention of the material. That is, the ratio of the strength that remains after the light is retained.

- Q: Can geotextiles be used in seawall construction?

- Yes, geotextiles can be used in seawall construction. Geotextiles are commonly used as a reinforcing material in seawalls to provide additional strength and stability. They help control erosion, prevent soil movement, and provide filtration to ensure proper drainage in seawall structures.

- Q: How do geotextiles help with pavement maintenance?

- Geotextiles help with pavement maintenance by providing reinforcement and stabilization to the pavement structure, preventing the migration of base materials, reducing cracking and rutting, and improving the overall longevity and durability of the pavement.

Send your message to us

Hanes Geotextiles Wooden Silt Fence/Polypropylene Woven Fabric 100gram

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords