Halfmoon Glass for Windows and Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Piece/Pieces watt

- Supply Capability:

- 200 Case/Cases per Month 4-5 20''GP/MONTH watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Acid Etched Glass,Decorative Glass,Heat Absorbing Glass,Heat Reflective Glass,Insulated Glass,Low-E Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Figured Glass,Frosted Glass,Laminated Glass,Stained Glass,Tempered Glass Type: decorative glass

Color: clear or colored for door glass

Size: as your requirements for door glass

Packaging & Delivery of Halfmoon Glass

Packaging Details: Packed in wooden crates with paper interleaved.

Delivery Detail: Within 30 days after the receipt of down payment.

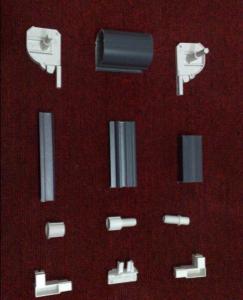

Specifications of Halfmoon Glass

1) 13 years manufacturing experience for door glass

2) ISO9001, IGCC/IGMA,SGCC cetification

3) Best Quality & Competitive Price

Specification:

1. Material: strong tempered glass, patterned glass, sheet glass

2. Color: clear or colored are all available for door glass.

3. Specification/Size: 914.4*558.8, 1219.2*558.8, 1625.6*558.8, 1219.2*203.2, 457.2*177.8, 1135*205 etc. We can cut the glass into your required size for door glass

4. Thickness: 17 mm to 25.4 mm.

5. Technology: clear tempered glass, acid etched glass, mistlite backing, panel glass with bevels and clusters, colored glass, patterned glass for decorative door glass

6. Application: kitchen, entry doors, interior doors, windows, veranda, cathedral etc.

- Q: Water glass, ceramics, ordinary cement, quartz glass, what are these chemicals?

- Water glass chemical formula is Na2SiO3.9H2O, usually quartz and caustic soda (NaOH) wet production, or with quartz and soda ash (Na2CO3) dry production, both need high temperature.

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Acrylic board and plexiglass"Organic glass" from English Organic Glass. in recent years in some areas will be made of transparent plastic sheet all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called the acrylic plate.

- Q: The difference between crystal glass and glass

- To strike lightly or with fingers. Crystal glass can produce metal crisp sound, and waves a beautiful lingering in the air. We will see at the reception banquet, high-end glasses scenes in the movie, a kind of glass between the collision sound is. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.

- Q: How is glass made? What are the main ingredients?

- Heat treatment. Through annealing, quenching and other processes, to eliminate or produce glass internal stress, phase separation or crystallization, and change the state of glass structure.

- Q: Method for cutting thick glass

- Mechanical cutting glass:Mechanical cutting glass is the mechanical property of glass with low tensile stress. The diamond or emery is used to cut the surface, and the force is cut off because of tension.(1) when glass cutters do not cut very thick glass, they use diamond glass cutters inlaid with diamond at the ends of brass and cut ordinary flat glass, and often use super hard knife wheels. In addition, when cutting, adding kerosene and other liquids, the incision and tool life are better protection. In addition, to lead the soft glass tube, but also useful to cut the file.(2) diamond saw cutting diamond saw is not limited to glass, but also widely used in the cutting of germanium, silicon, ceramics, crystal and so on. Compared with common grit or ordinary abrasive saw, diamond saw has high cutting efficiency. Generally, grinding fluid is used during cutting. The bonding materials of diamond saw include metal, thermosetting resin, ceramic and so on. But the metal saw such as brass is usually cut. The thickness of saw blade is about 0.2 ~ 7ram. Cutting method is divided into outer circle cutting, inner circle cutting and band saw cutting.

- Q: What are the chemicals in glass?

- Common raw materials are quartz sand, feldspar, calcite, calcium carbonate, three, two aluminum oxide, sodium carbonate, borax and so on.

- Q: Glass fiber reinforced plastic (FRP) is a new type of composite material. What is the raw material?

- Building materials market will be on sale. Glass fiber reinforced plastic (FRP) is a kind of composite material made of glass fiber and one or several thermosetting or thermoplastic resins, such as phenolic resin, epoxy resin, polyester resin, polyimide resin, etc.. Glass fiber reinforced plastic is a new type of composite material developed in early twentieth Century. It has many advantages, such as light weight, high strength, anticorrosion, heat preservation, insulation, sound insulation and so on. The first composite was fiberglass, in fact, it had nothing to do with steel. There is no iron in glass fiber, nor is it a composite of glass and steel.

- Q: Which is the best solar water heater tube?

- The surface of the vacuum heat collecting tube is smooth and clean, the pipe body has no spots, no air lines, no scratches and no film forming. (this phenomenon will affect the collection efficiency and beauty).

- Q: The younger brother wants to know how the octagonal bead is produced Do you use one side of the machine to grind it? What kind of material is usually used in China? Is the price fixed according to the material used?

- Generally use K5 more.Grade a crystal beads: flat emery abrasive disc cutting, flat polishing disc polishing one by one, and thus high gloss. Glittering and translucent!

- Q: Use of glass flake cement

- Coatings containing glass flakes are much harder than epoxy or polyester resin without glass flakes, and therefore have higher surface abrasion resistance.

1. Manufacturer Overview

| Location | Jiangsu,China (Mainland |

| Year Established | 2002 |

| Annual Output Value | |

| Main Markets | North America Southeast Asia Oceania |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Halfmoon Glass for Windows and Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Piece/Pieces watt

- Supply Capability:

- 200 Case/Cases per Month 4-5 20''GP/MONTH watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches