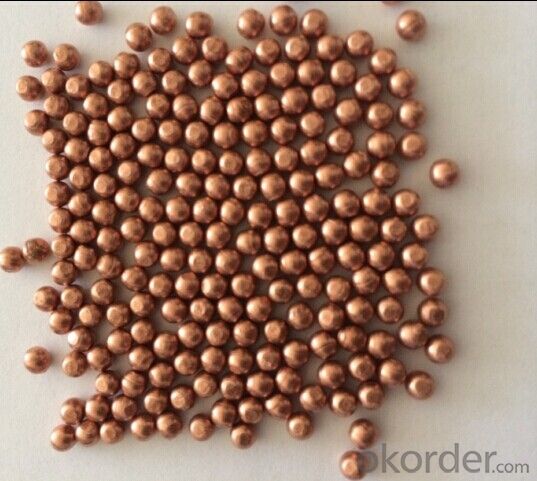

Grinding Ball Stainless Steel Ball Massage Ball Bearing Ball Steel Shot Valve Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product details:

Material : AISI420; AISI440C;304;316;316L; AISI210 etc

Grade: G10-G1000

Size: 1MM-60MM

1. AISI 420 Stainless Steel Ball

Magnetic, Harden-able,

fair corrosion resistance

used for special bearings and valves where

Balls requiring a combine -action of hardness and

corrosion resistance

2. AISI 440C Stainless Steel Ball

Magnetic, highest hardness,

good corrosion resistance

used in bearing nozzles and valves where

lubrication is poor or absent

3. AISI 304 Stainless Steel Ball

austentitic, corrosion resistance,

slightly magnetic, however annealing

can makes it non - magnetic

Used in valves and relevant application ,

food products, aerosols, home sprays,

perfumes and medical equipment.

4. AISI 316 Stainless Steel Ball

non - magnetic, good corrosion

resistance even when exposed to

marine atmosphere and sulfuric acid.

used in presence of sulphuric, phosphoric

and acetic acids.

Mainly used in chemical, paper and textile industries.

What can we do for you?

1) Chinese Professional Manufacturer for Steel Ball

2) Easy Storage

3) Factory Price & Best Quality

4) Accept Custom Order

5) Fast Delivery

6) OEM Service

7) Emergency Stocks

8) We promise all inquiry and emails will get our reply within 24 hours.

9) Convenient Payment:

T/T, 30% deposit, 70% before shippment; L/C at sight.; 100% Western Union in advance.

10) Professional production team, production line, experienced technical experts who engaged in steel balls for more than 20 years. We have the professional production line for steel balls.

- Q: What are the different types of steel forgings and castings?

- There are various types of steel forgings and castings, including open-die forgings, closed-die forgings, and rolled-ring forgings. In terms of castings, common types include sand castings, investment castings, and die castings. Each type has its own unique characteristics and applications in different industries.

- Q: How is steel used in the production of pipelines?

- Steel is commonly used in the production of pipelines due to its strength, durability, and corrosion resistance. It is used to manufacture the pipe itself, providing a reliable and long-lasting material for transporting fluids and gases over long distances. Steel pipes are also commonly coated or lined to further enhance their resistance to corrosion and improve their overall performance in various environments.

- Q: What are the advantages of using steel wire ropes?

- There are several advantages of using steel wire ropes. Firstly, steel wire ropes have high strength and durability, making them suitable for heavy lifting and pulling tasks. They can handle high loads and provide excellent resistance to wear and tear. Secondly, steel wire ropes have excellent flexibility, allowing them to be used in various applications and easily maneuvered around corners and obstacles. Thirdly, steel wire ropes have a long lifespan, requiring less frequent replacements compared to other materials. Lastly, steel wire ropes have high resistance to corrosion, making them suitable for outdoor and marine environments.

- Q: How do steel products contribute to the telecommunications and networking industry?

- Steel products play a crucial role in the telecommunications and networking industry by providing the necessary infrastructure for transmitting and distributing data. Steel towers and poles are used to support antennas and satellite dishes, enabling wireless communication and connectivity. Additionally, steel cable trays and racks are utilized for organizing and protecting cables in data centers and telecom facilities. In essence, steel products provide the backbone for the efficient functioning of telecommunications and networking systems, facilitating reliable and high-speed communication worldwide.

- Q: What are the applications of steel gratings?

- Steel gratings have a wide range of applications due to their strong and durable nature. Some common applications include industrial flooring, walkways, platforms, stair treads, drainage covers, and security fences. They are also used in construction, oil and gas industries, transportation, and various other sectors where strength, stability, and drainage are essential.

- Q: What are the common applications of steel products in the automotive industry?

- Steel products are widely utilized in the automotive industry for various applications. Some common uses include the manufacturing of car bodies, chassis, engine components, suspension systems, and various structural parts. This is primarily due to steel's exceptional strength, durability, and ability to be molded into complex shapes, making it an ideal material for ensuring safety, enhancing performance, and ensuring longevity in vehicles.

- Q: How is steel used in the manufacturing of electrical equipment?

- Steel is commonly used in the manufacturing of electrical equipment due to its strength and durability. It is often used to create sturdy frames and enclosures for transformers, generators, motors, and other electrical components. Additionally, steel is also used for the production of electrical transmission towers and other supporting structures for power distribution systems.

- Q: How are steel forgings used in the production of power generation equipment?

- Steel forgings are used in the production of power generation equipment due to their exceptional strength, durability, and reliability. These forged components, such as turbine rotors, shafts, and casings, are able to withstand the extreme conditions and heavy loads associated with power generation. The forging process ensures a uniform grain structure, eliminating weak points and improving the overall performance and longevity of the equipment. Additionally, steel forgings can be customized to meet specific design requirements, allowing for efficient and safe power generation operations.

- Q: What are the different types of steel products used in the manufacturing of packaging materials?

- Some of the different types of steel products used in the manufacturing of packaging materials include steel sheets, steel coils, steel strapping, and steel drums. These steel products provide strength, durability, and protection for various packaging applications.

- Q: How do steel products contribute to the construction of sports facilities and stadiums?

- Steel products play a crucial role in the construction of sports facilities and stadiums due to their strength, durability, and versatility. From the framework and roof structure to the seating and support systems, steel is widely used in various aspects of sports facility construction. It provides the necessary structural integrity to withstand heavy loads and adverse weather conditions, ensuring the safety and longevity of these venues. Moreover, steel's flexibility allows for innovative and complex architectural designs, enabling the creation of iconic stadiums that capture the essence of sporting events.

Send your message to us

Grinding Ball Stainless Steel Ball Massage Ball Bearing Ball Steel Shot Valve Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords