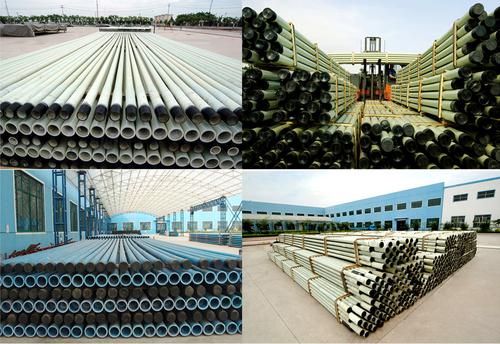

GRE Composite Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20kilometres m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Passed the ISO9001 quality system in 1998, three times acquired Jiangsu province quality management prize, the high pressure piping product has passed an American API certificate. In 2006,FRP pipes with"Lianzhong"Brand" certificate.Zhongfu Lianzhong group is the only company with large capacity of FRP products exporting.

The products were exported to Pakistan, Vietnam,Malaysia,Indonesia,Italy,Germany etc,;it is the only manufacturer with supplying large diameters FRP pipes in construction of nuclear station,Lianzhong supplied large diameters FRP pipes to the second term of Qinshan Nuclear Power Station,Tianwan Nuclear Power Station etc...

Zhongfu Lianzhong insists on developing with technical innovation. Lianzhong imported advanced winding technology of pipes,tank and high pressure pipe from italy and U.S.A firstly in China. Now Lianzhong has more than twenty production lines of pipes, tanks and high pressure pipes.The total annual capacity of FRP pipes,pipes with sand filler,tanks etc.is 20000 tons. Because of credible quality and good service,Lianzhong's products have been proved by so many years practical use in various fields.Those products have won widely favorable comments from customers.

- Q: What kind of material does glass steel ship honeycomb board use?

- The product adopts composite honeycomb structure, prefabricated glass fiber reinforced plastic panel, high strength glass fiber grid cloth and aluminum honeycomb core material, and is compounded by hot pressing. Because of the high strength of the grid cloth, the impact resistance and flexural strength of the composite board are very high.

- Q: What kind of project needs fiberglass pipe?

- Glass fiber reinforced plastic products are characterized by corrosion protection, high temperature resistance, humidity resistance, alkali resistance, etc., where it is necessary to use the glass fiber reinforced plastic pipe!!

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- One is to finish insulation wrap (Qin material cloth) and then wrapped a layer of glass paper....... The other is a glass lined steel pipe outside the pipe and then foamed and insulated inside

- Q: Underground garage inorganic glass fiber reinforced plastic wind pipe water out of the way?

- The condensed water duct wall: when the fan start, rapid air circulation in the inorganic pipeline flow, pipeline internal and external space of large temperature difference, leading to the underground garage of the water vapor condenses into water droplets freeze in the outer wall of the pipe. At this point, on the surface, it seems to seep through an inorganic pipe;

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe? What kind of material is good?

- Sand tube is more brittle, gfrpmp is relative to the glass tube can be called pure glass tube, glass tube is not with quartz sand, the two pipes generally used in different areas, the pure glass pipe can be used in most areas, but the sand tube is generally only used in the political field, especially is the large diameter sand tube.

- Q: How to install FRP pipe correctly

- Field bonding process is usually provided by glass fiber reinforced plastic manufacturers, if there is no way, I can provide some experience for reference, there is little information, experience only.

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- Glass fiber reinforced plastic words, such as what you said, for ordinary construction workers, a little difficult, after all, opening and bonding can not do under high pressure or long-term use of water leakage.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- The interface can be bonded with epoxy resin adhesive. The epoxy resin strongly adhere to the two materials, but the bonding surface must be clean.

- Q: Are there any differences between FRP pipes and FRP pipes?

- The mechanism glass magnesium composite pipe is made of glass cloth, magnesium and earth, which is hard to burn. The glass fiber reinforced plastic pipe is made of glass cloth and resin, and it is inflammable and light in weight.

- Q: How can FRP tanks be connected to steel tubes?

- Glass tube and carbon steel pipe connection, at present, the most reliable way of connection is only flange connection, other such as on-site bonding, because the two kinds of material is not the same, the quality is not very stable after bonding!

Send your message to us

GRE Composite Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20kilometres m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords