Composite High Strength Corrosion-Resistant Lightweight Marine GRE Pipe

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 2000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Specification:

1.Producer :Lianyungang Zhongfu Lianzhong Composites Group Co., Ltd.

2.Place of production : No 6-1. Linhong Avenue, Dapu Industrial Park, Lianyungang Economic and Technological Development Zone, Lianyungang City, Jiangsu Province, P. R. China.

3.Proudets description: Glassfibre reinforced epoxy pipes and fittings for marine applications.

4.Type:

4.1 LZ-MA6, LZ-MA10, LZ-MA16, LZ-MA25.

4.2 LZ-MA6-C, LZ-MA10-C, LZ-MA16-C, LZ-MA25-C;

4.3 LZ-MA6-F, LZ-MA10-F, LZ-MA16-F, LZ-MA25-F;

4.4 LZ-MA6-C/F, LZ-MA10-C/F, LZ-MA16-C/F, LZ-MA25-C/F.

Notes : LZ-lianzhong ; MA-marine applications ; 6/T0/16/25-Nominal pressure rating ; C- Conduetive ; F-Fire Endurance.

5.Nominal Pressure Rating:0.6MPa,1.0MPa,1.6MPa,2.5Mpa.

6.Nominal Diameter (mm):DN25-DN1300

7.Maximum Working Temperature:100°C.

8.Service External Pressure:3-5bar.

9.Fittings:Flanges, elbows, tees, saddles, reducers, couplings, penetration piece and double O-ring bell and spigot joints.

10.Type of pipe joints:taper/taper bonded joint,flange,lamination joint ete.

11.Raw Materials:Epoxy resin, glass fiber

12.Service Life: 30 years.

13.Range of Application:Ballast system, fresh water, cooling water systems, sanitary drains (internal), ventilation, sea water, nonessential systems, and scrubber effluent line, et. marine and offshore piping systems for sea water, fresh water, sanitary/drains/scuppers and non-essential services in locations requiring IMO A753.

14.Jet Fire Resistance , Fire Endurance, Low Flame Spread,Smoke & Toxicity:The piping system has been tested to fire endurance L3, according to IMO resolution a .753(18) The piping system has been tested to low flame spread, according to IMO international code for application of fire test part 5 The piping system has been tested to smoke& toxicity, according to IMO international code for application of fire test part 2.

15.Design standards:Rules and regulations for classification society.

• IMO A.753(18) Guidelines for the application of plastic pipes on ships.

•IMO 2010 FTP international code for application of fire test procedures.

•ASTM F1173-01 Standard specification for Thermosettingresin fiberglass pipe systems to be used for marine applications.

•API 15LR Specification for low pressure fiberglass line pipe and fittings.

•ASTM D2444, ASTM D257, ASTM D1599, ASTM D2412 ,ASTM D2924, ISO 75-2: 2004.

Products Advantages:

1.High strength, GRE pipe has the same strength as steel pipe.

2.Light weight: 24% weight of ductile iron, it is convenient for installation in the absence of heavy machinery and large tools.

3.Corrosion-resistant: the surface of internal and external can resist many kinds of corrosion chemicals, seawater, freshwater, waste water and bacteria.

4.The long life cycle and low cost: there is almost no maintenance costs after installation and use,and it has higher lifetime compared with steel pipe.

Jet fire and fire-resistant experiment Level 3 fire-resistant experiment

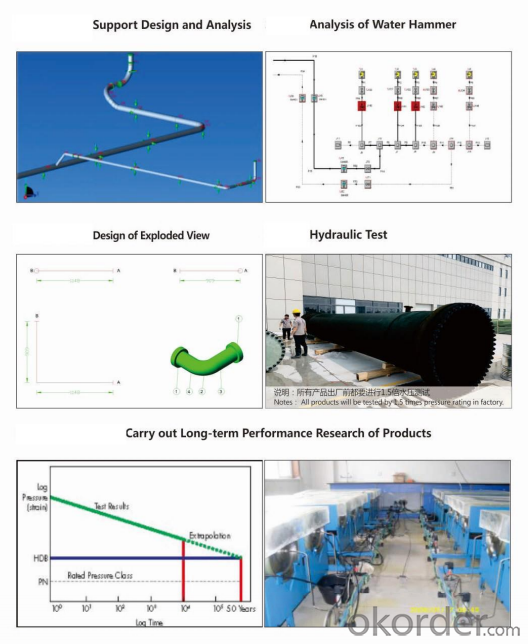

Products Design and Quality Control;

1.We have core intellectual property rights in GRE production , and many techonlogy proprietary in GRE industry.

2.Adopting various design methods and software for product design, cooperate with customers to complete product and pipeline design.

3.Using advanced raw materials and formula ensure product quality.

4.Production line is mainly controlled by automation, which controls keys parampeter winding angle , winding speed and so on.

5.From raw material inspection , winding process, curing process, process control and monitoring, and inspection, all workings are performed according to technological requirements and standards strictly.

Physico-Chemical Performance Index:

Index | Unit | Values | Test method |

Coefficient of thermal conductivity | w/m.℃ | 0.33 | ASTM D177 |

Hoop elasticity modulus | 10°mm/mm/℃ | 12.7 | ASTM D696 |

Discharge coefficient | Hazen Williams | 150 | In-House |

Absolute roughness | 10^6 m | 5.3 | In-House |

Density | g/cm³ | 1.95 | ASTM D792 |

Hoop tensile strength | MPA | 250 | ASTM D1599 |

Hoop elasticity modulus | GPA | 250 | ASTM D1599 |

Poisson's ratio | - | 0.38 | ASTM D1599 |

Axial tensile strength | MPA | 125 | ASTM D2105 |

Axial elasticity modulus | GPA | 12.5 | ASTM D2105 |

Installation Services:

For each project, Zhongfu Lianzhong will dispatch installation service engineers to the jobsite.before installation, the installation team will be trained, and the qualified installation workers will be issued with training qualification certificate. during the installation process, Zhongfu Lianzhong's installation service engineers will provide on-site guidance for the key points. Zhongfu Lianzhong also can undertake project general contractor.

Typical Cases:

Singapore Pacific International Lines ( PTE) LTD

Singapore Pacific International Lines ( PTE) LTD

Singapore Pacific International Lines ( PTE) LTD

America Mangrove Partners

America Mangrove Partners

America Mangrove Partners

- Q: What are the differences between inorganic FRP pipes and plexiglass pipes, what are the advantages and disadvantages?

- Inorganic glass fiber reinforced plastic wind pipe: magnesium magnesite soil and glass fiber mesh cloth made of advantages: flame retardant shortcomings: large proportion, low strength

- Q: Mending method for glass fiber reinforced plastic pipe

- The method for mending and mending the glass fiber reinforced plastic pipe is hand paste, and the repairing steps are as follows:The stones must be taken away so that the pipes are restored to their original shape.Into the pipe, grinding first and lining the lining. If you can't get into the pipe, polish it from the outside, polish it to the lining, and then make a new lining.Reinforce the structure with a cloth.

- Q: What qualifications do FRP pipes need to export to Australia?

- Need to comply with the local certification standards or international certification standards certification system

- Q: What is the heat preservation of the plumbing pipe now? I'd like to use fiberglass Seek help from a master

- Glass cotton + glass steel pipe shell: high cost, long construction cycle, good insulation effect.Rock wool insulation: high prices, poor construction conditions, poor heat preservation, water after a mess.Polyurethane foam + yellow jacket: high price, good insulation effect.Galvanized sheet + glass cotton: cheap price, quick construction, good insulation effect.

- Q: Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- Because the resin curing mechanism of FRP products is resin, resin agent, resin curing agent together to react, and release a lot of heat, this process does not affect the curing process because of a small amount of water and at the same time, if you have a little bit of water molecules would because of the large amount of heat emitted by evaporate, so does not affect the bonding of glass and steel that will not affect the glass steel pipe interface

- Q: Can FRP pipes be used in heating pipes?

- Glass steel pipe road does not belong to common heating pipe material.Heating pipe requirements are solid, high temperature, pressure, easy connection, convenient construction.Usually, heating pipes are made of steel and materials are more common.

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Dislocation will cause the pipe to burst. The pressure is different, and the pipe will burst

- Q: What are the main points for the installation of FRP ducts?

- Organic pipe basically no sales, mainly too expensive, rather than bad, and now most of them are inorganic pipe, or white iron pipe, there is a kind of polyurethane, but rarely used

- Q: What are FRP pipes used for making? What raw materials?

- The glass tube with its unique strong corrosion resistance, smooth surface materials, low energy consumption and long service life (50 years), convenient transportation and installation, maintenance and many other advantages of low cost and low cost in electric power, petroleum, chemical industry, papermaking, city water supply and drainage, sewage treatment plant, seawater desalination, gas transportation other industries have been widely applied.

- Q: A basic overview of FRP pipes

- FRP pipes are used in petroleum, chemical and drainage industries. Glass fiber reinforced plastic pipeline production in China has developed rapidly, and the quantity has been increasing year by year, and the scope of application and departments are becoming wider and wider.

Send your message to us

Composite High Strength Corrosion-Resistant Lightweight Marine GRE Pipe

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 2000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.