Composite Durable and Corrosion-Resistant Gre Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Advantages:

1. Durable in use and corrosion-resistant:the surface of internal and external can resist many kinds corrosion of chemicals, crude oil. injected water and bacteria.

2. Light weight: 24% weight of ductile iron, it is convenient for installation in the absence of heavy machinery and large tools.

3. Low cost: Internal surface can reduce friction and the cost of transporting by pump.

4. Efficient and eneray saving: GRE pipe compared with steel tube can reduce the consumption of heat.

5. The solution of pipe system: The whole FRP pipe have different size, pipe joints, pressure rating for choice.

6. The long life cycle and low cost: There is almost no maintenance costs after installation and use, and it has higher lifetime cost compared with steel tube.

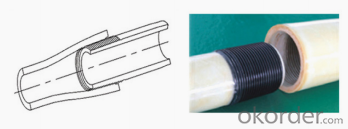

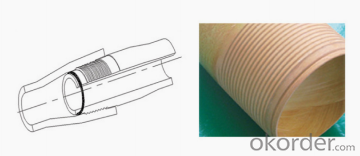

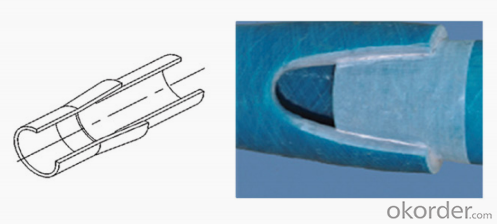

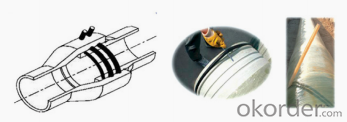

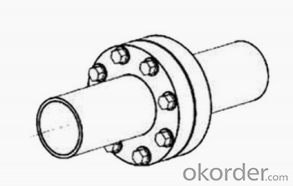

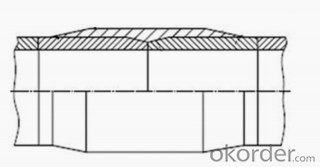

Joint type:

1. API thread application: High pressure oil & gas & water pipeline

2.T thread joint application: High pressure oil & gas & water pipeline

3.Bonding joint application: Underground low pressure pipeline

4.Locking key joint application: Underground low pressure pipeline

5.Flange joint application: Pipe and pipe or pipe joint other equipment

6.Lamination joint application: Low pressure pipeline connection

Produts Application:

1.Oil & gas-onshore:

Crude oil gathering line

Injected water

Macromolecule

Process pipeline in station

LNG pipeline

1. Vessel and offshore platform

Ballast water

Cooling water

DrainageFresh water pipe

Drinking water

Fire fighting water pipe

Sea water transport

Sewage transport

2. Bittern special purpose

Transport bittern

Transport sewage

3. Underground pipe and casing pipe

CBM casing pipe

Shale gas casing pipe

Underground oil pipe

Oil casing pipe

Product Performance:

The corrosion picture comparison between ordinary steel pipe and FRP pipe:

Performance comparison between ordinary steel pipe and FRP pipe:

Comparison Item | GRE pipe | Ordinary Steel Pipe |

Corrosion Resistance | Good corrosion resistance | Bad corrosion resistance |

Service Life | 20-30 years(the designed service life is more than 50 years ) | 5-10 years (nocathodic protection and preservative) |

Frictional Resistance | Smooth inner wall can reduce the accumulation of paraffin and scale;Low surface friction increase the flow of fluid velocity | The rough inner surface is easy to form scale and paraffin deposition;High surface friction leads to loss of workpressure |

Insulation Performance | There is no minimum and additional insulation material" requirement under high temperature and harsh environment | A lot of heat loss under the condition of high temperature |

Engineering Installation | Light weight, low cost of installation and transport | High weight, high cost of installation and transport |

Maintenance Fecs | It almost need no repair | Need anti-corrosive paint, cathodic protection and corrosion monitoring |

Environmental Performance | Low energy consumption in the process of productionand use | High energy consumption in the process of production and use |

Production Information:

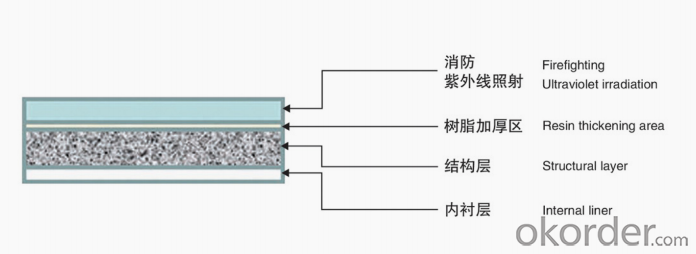

GRE wall structure:

∙ Pipe internal liner is used for anti-corrosion

∙ Pipe structural layer is used for pipe strength

∙ Anti-uv protection can used in pipe external to resist uv & the weathering exposure and environmental protection

∙ If high flow conducting electrostatic discharge need, GRE pipe can be used to conduct harmful static electricity discharged in the danger zone

In the fire, protective layer meet the fire resistance performance of protection box, required by firefighting, and produce less harmful gas.

Jet fire and fire-resistant experiment:

Level 3 fire-resistant experiment:

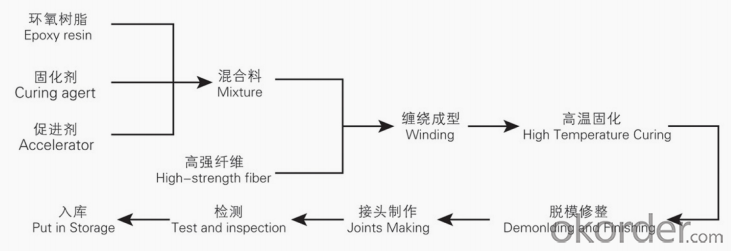

Production Method:

∙ Filament winding is used for both pipe and fitting production.

∙ The fiber glass will be winded on the mandrel after soaked into the resin. The mandrel will be rotated according to programmed mode.

∙ Multiply mandrels can be winded at the same time with one winding machine which has improved the work efficiency and guaranteed the quality.

∙ The winding of pipe fittings I flange, elbow, tee, coupling ) are made of two axis winding machines.

Production Process:

Quality Control:

Universal tester Differential scanning calorimeter (DSC)

Drying oven Fatigue tested machine

Before delivery, all pipes conduct 100% hydrostatic pressure monitoring in accordance with API standard.

Standard & Specification:

∙ API 15HR Specification for High Pressure Fiberglass Line Pipe

∙ API 15LR Specufcation for Low Pressure Fiberglass Line Pipe and fittings

∙ ISO 14692 Petroleum and natural gas industries - Glass-reinforced plastics (GRP) piping

∙ AWWA C950 Standard for fiberglass pressure pipe

∙ AWWA M45 Fiberglass pipe design

∙ IMO Res.A753(18) Plastic pipes on the ship

∙ ASTM F1173 Standard Specification for Thermosetting Resin Fiberglass Pipe Systems to Be Used for Marine Applications

∙ ASTM---D2996 Standard Specification for Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

∙ API 5B Casing, tubing. line pipe thread specification

- Q: Why FRP pipes for outdoor waste gas treatment equipment are selected?

- Therefore, the outdoor waste gas treatment equipment is usually made of glass fiber reinforced plastic.

- Q: The difference between FRP process tubes and GRP tubes

- Process tubes are mostly pure glass steel, not sand, and sand pipe, of course, is added sand.

- Q: What is the stiffness of FRP pipe?

- Ring stiffness refers to a technical index of FRP pipes subjected to external pressure.

- Q: Mending method for glass fiber reinforced plastic pipe

- Tip: if glass fibre reinforced plastic pipe is broken, it is suggested to replace it with new pipe.

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- A 300 hole bonding a short tube, in the installation of a valve (see what install valves, iron needs a steel plastic conversion, direct bonding glass steel flange, a glass tube) special glue (a few years ago had forgotten what, like what's called 507), this thing is good to buy special glass steel where there is, the effect is quite good

- Q: Are there any differences between FRP pipes and FRP pipes?

- The mechanism glass magnesium composite pipe is made of glass cloth, magnesium and earth, which is hard to burn. The glass fiber reinforced plastic pipe is made of glass cloth and resin, and it is inflammable and light in weight.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Epoxy coal tar coating consists of two main components with epoxy coal asphalt composition, is a (epoxy) B (curing agent) two-component coating, with good adhesion, toughness, moisture resistance, water resistance, chemical resistance, has the properties of prevent various ions through the film, and is coated with objects with the expansion of shrinkage characteristics. The paint film never falls off or cracks.

- Q: Can FRP pipes be used in heating pipes?

- FRP pipes are generally not used in heating pipes, because the use temperature of FRP pipes is limited, as detailed below:1. universal unsaturated polyester FRP can only be used for less than or equal to 60 degrees (HG/T20696-1999)2. bisphenol A unsaturated polyester FRP can only be used for less than or equal to 100 degrees HG/T20696-1999)3. vinyl unsaturated polyester glass fiber can only be used for less than or equal to 120 degrees HG/T20696-1999)4. epoxy FRP can be used for less than or equal to 90 degrees HG/T20696-1999)5. glass fiber reinforced plastic sand holding pipes can only be used for less than or equal to 50 degrees (GB/T21238-2007)

- Q: What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- Glass fiber reinforced mortar pipe lightweight high strength: for the same diameter of the unit length, weight, RPM tube only carbon steel 1/3, cast iron pipe 1/5, prestressed concrete pipe 1/10, easy transport, loading and unloading.

- Q: What are FRP pipes used for making? What raw materials?

- So people began to think, if you can make a kind of glass has both hardness, high temperature resistance, corrosion resistance of the nature, but also with steel as hard, not broken characteristics, then this material will be of great use. People have made such a composite material after research and experiment. It is a glass pipe and steel, can stand shoulder to shoulder.

Send your message to us

Composite Durable and Corrosion-Resistant Gre Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.