Graphite Die Mold Inc Graphite Sintering Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

graphite part:ISO9001

high quality with best price

produce graphite mould as per drawing

supply graphite product stably

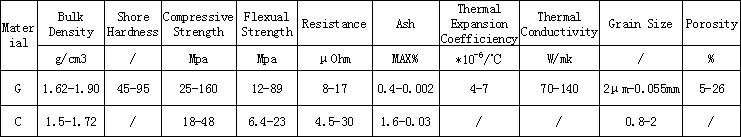

The physical and chemical properties of C and G material:

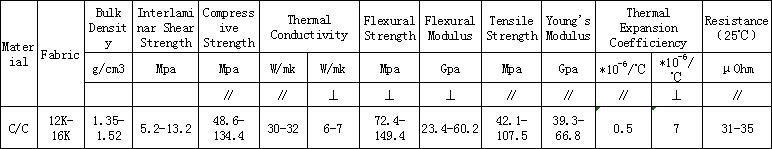

The physical and chemical properties of C/C material:

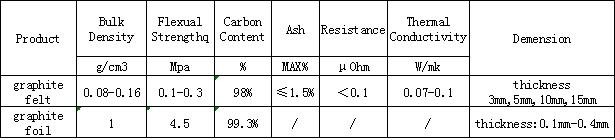

The physical and chemical properties of other material:

Products of carbon and graphite are widely used in such fields as industrial furnaces, mono-crystalline silicon machinery, mono-crystalline silicon machinery, electron, semi-conductor, metallurgy, oil, chemistry, textile, electrical machinery, electrical equipment, electrical furnace, traffic, communication industry, medicine, etc.

Providing graphite heating systems used in mono-crystalline silicon and multi-crystalline silicon industrial furnaces (such as heaters, thermal insulation material, insulation materials, etc.)

Providing graphite moulds, molds, graphite felt, graphite foil, graphite rod, graphite sheet, utensils, crucibles used in furnaces(such as graphite boats ,outer molds, mounting plates, etc.)

Providing graphite crucibles and utensils used for particular amorphous metal, rare metal, and non-ferrous metal and crystallizers for the growth of ferrous metal, etc.

Providing mechanical seal parts, graphite rings, graphite bearings, graphite leaf

Providing carbon felt, carbon cords, graphite power, graphite felt, and compound carbon felt of different specifications

- Q: How is the graphite packing ring made?

- The graphite packing ring is made of a certain density graphite coil, which is mechanically cut into the mold and is made by cold pressing. It has the characteristics of corrosion resistance, high temperature resistance and self lubrication,

- Q: How do you sell graphite?

- There are many kinds of graphite. See what kind you want to sell.Graphite electrode: mainly used in the metal smelting industry. At present, the iron and steel industry is stagnant, and the graphite electrode is hard to sell.

- Q: How can the die steel be sharpened?

- Grinding method for white steel cutter of die:1, if you have edge, can use the fine flour water along the edge of the grinding stone;2, if not to use oilstone rough edged, dripping, and the vertical mill, namely the blade, which can then be used to drop down the edge grinding surface of fine aggregate.

- Q: How oil impregnated graphite mould

- In order to achieve a good soak, soak for at least two days more than two days in advance is ready

- Q: I do the mold, graphite is raw materials, production of products will have a lot of waste residue, in order to environmental protection, I would like to ask how to deal with it?

- Graphite is a good carburizing agent and can be sold to a foundry as an agent

- Q: Now the mould cavity EDM electrode material is the most widely used

- Copper and pure copper.In addition, larger cavity molding is often done with graphitePrecision machining is useful to tungsten, molybdenum, etc., but very few"

- Q: What can graphite be used to make dry batteries?

- Dry battery in the carbon graphite is made;

- Q: Do the hot bending toughened film with graphite mould. How do you deal with the pressure on the surface?

- The cleaned copper seems less natural. With the passage of time, still will be black and the re emergence of copper oxide layer. However, we still can not guarantee that the new copper oxide layer will generate uniform, black spots appear not coin surface. So, the best cleaning copper oxide layers of naturally generated antique, give a person with the old feeling.

- Q: Why is Shi Mozhou hollowed out?

- Graphite mold is made of artificial graphite by mechanical processing. Therefore, graphite mold sometimes become a graphite boat, also known as graphite boat.

- Q: Graphite mold, graphite ring and other graphite products, how about anti oxidation coating?

- Therefore, the temperature resistance is more stable, brushing on graphite to form a dense coating, with rust prevention, corrosion resistance, high temperature resistance, oxidation resistance, wear-resistant and other characteristics.

1. Manufacturer Overview

| Location | Beijing,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 70.00% Domestic Market 10.00% Eastern Europe 10.00% Western Europe 5.00% North America 5.00% Southeast Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | xingang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Graphite Die Mold Inc Graphite Sintering Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches