High Purity Large Graphite Mold

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

graphite qaulity:ISO9001

produce graphite mould as per drawings

supply graphite product stably

mould making in industry field

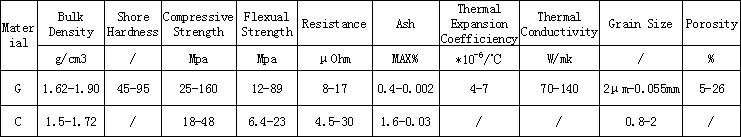

The physical and chemical properties of C and G material:

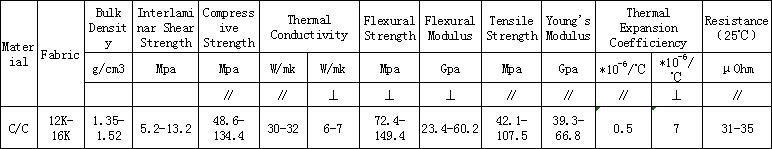

The physical and chemical properties of C/C material:

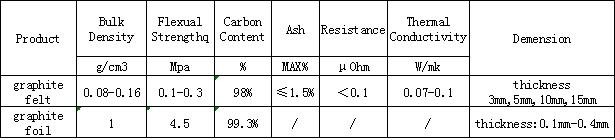

The physical and chemical properties of other material:

Products of carbon and graphite are widely used in such fields as industrial furnaces, mono-crystalline silicon machinery, mono-crystalline silicon machinery, electron, semi-conductor, metallurgy, oil, chemistry, textile, electrical machinery, electrical equipment, electrical furnace, traffic, communication industry, medicine, etc.

Providing graphite heating systems used in mono-crystalline silicon and multi-crystalline silicon industrial furnaces (such as heaters, thermal insulation material, insulation materials, etc.)

Providing graphite moulds, molds, graphite felt, graphite foil, graphite rod, graphite sheet, utensils, crucibles used in furnaces(such as graphite boats ,outer molds, mounting plates, etc.)

Providing graphite crucibles and utensils used for particular amorphous metal, rare metal, and non-ferrous metal and crystallizers for the growth of ferrous metal, etc.

Providing mechanical seal parts, graphite rings, graphite bearings, graphite leaf

Providing carbon felt, carbon cords, graphite power, graphite felt, and compound carbon felt of different specifications

- Q: Can graphite be used as a gear?

- Graphite is a kind of brittle non wearing material. It can not be used as a torque transmitting device. It can be used in the situation where the requirement of accuracy is not high

- Q: How can the die steel be sharpened?

- Also can be used for plastic, nylon, or iron material, because the material used? If the roughness of the alloy knife is not good, white steel can get higher roughness, but it must be fine car, processing capacity of 0.3 to 0.8, if the processing of large amount of coolant must be added. A small amount of 45 steel can also be done.

- Q: How long is the service life of graphite boat sticking point?

- Graphite mold is made of artificial graphite by mechanical processing. Therefore, graphite mold sometimes become a graphite boat, also known as graphite boat.

- Q: What are the specific categories of Shi Moru?

- With good high temperature lubrication, protect the mold, reduce wear and tear. Excellent high temperature coating, 600-1200 degrees does not fall off and does not burn, the protection of wire material is not oxidized, easy to save, no spoilage. Used in drawing lubricant. Such as tungsten wire, molybdenum wire, rhenium wire, thorium wire and other lubricants.

- Q: I do stretch die for nodular cast iron, which can tell me the mold heat treatment method, the specific Cui fire a few degrees?

- Graphite annealing graphitizing annealing in order to make the eutectoid cementite in as cast microstructure of free cementite and pearlite decomposition, obtain high plasticity of ferrite nodular cast iron body, eliminate casting stress, improve the processing of.

- Q: We mainly do brass processing, using graphite mold life is too short, please advise

- The graphite mold can be extended by oxidation or soaking, and you can recommend it with your supplier. The price is sure to go up.

- Q: Plastic mold: several commonly used die repair method

- Laser overlaying repair laser welding is a kind of welding with laser beam as heat source focusing on large power coherent monochromatic photon stream. The welding methods usually include continuous power laser welding and pulsed power laser welding. The advantage of laser welding is that it does not need to be carried out in vacuum, but the disadvantage is that penetration is not stronger than electron beam welding. Precise welding can be realized by precise energy control during laser welding. It can be used in many metals, especially for welding difficult metals and dissimilar metals. At present, it has been widely used in mold repair.

- Q: Why should graphite column be used as solid lubricant in mould guide sleeve?

- Then, when you work, you can release the oil and form self lubrication.The mold guide sleeve generally has the Rongchang graphite guide sleeve, the self-lubricating bearing guide sleeve

- Q: Hot work die steel H13, in the process of cooling with graphite milk or water? Is there a crack with water?

- (1) it has high hardenability and high toughness;(2) excellent thermal cracking resistance and water cooling in workplace;(3) with moderate abrasion resistance, but also can improve the surface hardness of carburizing or nitriding process, but slightly reduced anti cracking ability;(4) because of its low carbon content, the two hardening ability of tempering is poor;

- Q: What are the differences between domestic and imported graphite? Who can tell me? What are they used in?

- Domestic graphite and imported density is not the same, Shaw hardness is not the same, domestic graphite particles than the import of graphite to be much larger

1. Manufacturer Overview

| Location | Beijing,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 70.00% Domestic Market 10.00% Eastern Europe 10.00% Western Europe 5.00% North America 5.00% Southeast Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | xingang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

High Purity Large Graphite Mold

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches