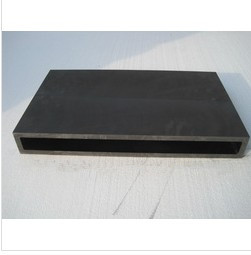

Graphite Mold Suppliers Horizontal Continuous Casting Flat Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 10,000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

- Application: Casting

- Technique: Die Molded

- Dimensions: Various of specification according to customers' requirement

- Bulk Density (g/cm³ ): ≥1.87g/cm³

- Porosity (%): 15%

- Compressive Strength: 65Mpa-85Mpa

- Composition: Carbon

Specifications

Graphite Mould1 high pure and density

2 mould for casting industry

3 high strength graphite

4 long using life

Graphite Mould

Feature:

1. Thermal stability: According to the quench acute thermal using conditions of graphite crucible, we will specially design the production procedure, so as to ensure the reliability of product quality.

2. Corrosion resistance: Even and fine basic design will delay the erosion of crucible.

3. Impact resistance: Graphite crucible can bear high thermal impact, so any process can be carried out.

4. Acid resistance: The adding of special materials will greatly improve the quality of crucible, especially its index of acid resistance., and will prolong the service life of graphite crucible.

5. High heat Conduction: High content of fixed carbon ensures the good heat conduction, shorten the time of dissolution, and remarkably reduce the energy consumption.

6. Control of metal pollution: The component of material under strict control will ensure that graphite crucible will not pollute the metals when dissolving.

7. Quality stability: The process technology of forming under high pressure and quality guarantee system will fully ensure the stability of quality

Graphite molds Materials index:

1.Content: 99.99%

2.Density: 1.87g/cm³

3.Compressive strength: 65mPa

4.Shore hardness: 55

5.Porosity: 15%

Application:

1. Brass continuous casting mould

2. Red copper continuous casting mould

3. Continuous casting mould for jewelry of gold, silver, platinum, etc.

4. Steel and stainless steel continuous casting mould.

By the shape of the cast product, it is divided into round bar mould, hollow tube mould, and shaped mould.

- Q: What are the electrodes on the die?

- Because the melting point of copper is 1083oC, and the melting point of graphite will appear in 3400oC. Graphite electrode can bear more machine setting conditions. These settings calculate the rate of metal removal and the amount of graphite loss. If the electrode material needs to be strictly controlled, the graphite electrode can be placed in a non - wear state (loss less than 1%) during rough machining. But the copper electrode is not used. Graphite electrode is easy to process. Graphite milling speed than other metal processing fast 3-4 times, and does not require additional manual processing.

- Q: What are the specific categories of Shi Moru?

- With good high temperature lubrication, protect the mold, reduce wear and tear. Excellent high temperature coating, 600-1200 degrees does not fall off and does not burn, the protection of wire material is not oxidized, easy to save, no spoilage. Used in drawing lubricant. Such as tungsten wire, molybdenum wire, rhenium wire, thorium wire and other lubricants.

- Q: What can graphite be used to make dry batteries?

- Graphite has good conductivity and stability, and is generally used as battery electrode (graphite electrode);

- Q: Plastic mold: several commonly used die repair method

- Mold plays a very important role in modern industry, and its quality decides the quality of product directly. To improve the precision and service life of mould, shorten the mould manufacturing cycle, many enterprises urgently need to solve technical problems, but in tooling process often collapse angle, deformation, wear, or even broken failure form. Therefore, the repair of the mold is also necessary. There are many ways to repair dies, such as EDM, argon arc welding, laser overlaying and brush plating. The argon arc welding repair uses the arc which is continuously sent between the welding wire and the workpiece as the heat source, and is welded by the gas protection arc ejected by the welding torch nozzle. At present, argon arc welding is a common method and can be applied to most major metals, including carbon steel and alloy steel. Metal inert gas welding for stainless steel, aluminum, magnesium, copper, titanium, zirconium and nickel alloy, due to low prices, is widely used in mold repair welding, but the disadvantages of the welding heat affected area, solder joints, the precision mold repair has been gradually replaced laser welding repair. Brush plating brush plating technology is the use of a special DC power supply equipment, power supply electrode plating, brush plating anode as the anode; power supply is connected with the workpiece, as the cathode. The brush plating pen is usually made of high purity fine graphite block as anode material

- Q: How are graphite molds made?

- Pressed into a block of graphite, with the morning rainbow CNC diamond cutting machine tools can be cut into graphite mold as required.

- Q: Why should graphite column be used as solid lubricant in mould guide sleeve?

- Graphite can be used as a solid lubricant, but most of them use ordinary oils as lubricants. Graphite is used here as a lubricant. The possible reason is to prevent the oil from polluting the products.

- Q: What is the die electrode?

- Red copper, or graphite can also be used as electrodes, with copper to fight things relatively light, and smaller particles, but the price is expensive, NC milling plus molding trouble.

- Q: Graphite used for mold, how much is the market price of one ton?

- Mainly used for electrodes!Processing is not very convenient

- Q: Is there any refractory coating material that can be coated on the graphite mold?

- Silicon, ceramic, carbon carbon coating, ceramic coating, cold, hot may fall off, the three also depends on your specific use environment to make a choice

- Q: Why do you choose the guide sleeve with bronze plus Shi Mozhu?

- Under dry friction conditions, we design a pre - formed synovial membrane on the surface of the bearing to ensure that the solid lubricant is transferred to the dual parts in the shortest possible time, and an effective solid lubricant film is formed

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | 20.00% South America 20.00% Eastern Europe 20.00% South Asia 20.00% Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Graphite Mold Suppliers Horizontal Continuous Casting Flat Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 10,000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches