Graphite Electrode With Preset Nipple - RP, HP, UHP for Optimal Electrical Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Graphite Electrodes:

We have a complete set of graphite electrode production lines. Our products have excellent structure, good electrical conductivity and thermal conductivity, high resistance to high temperature oxidation and corrosion characteristics. Common power graphite electrode for metallurgical refining, such as electric arc furnace steelmaking plant and other applications. As China's most professional manufacturer of graphite electrode, through the ISO9001:2000 international quality system certification. We are glad to be able to quote you the most competitive price according to your request.

2.Main features of Graphite Electrodes:

1).High electrical conductivity

2).High thermal shock resistance

3).High strength

3. Graphite Electrodes Images:

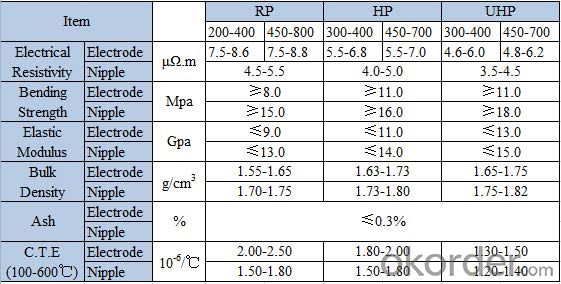

4. Graphite Electrodes Technical Parameters:

Diameter: As requirement

Grades: including RP, HP, UHP.

Nipples: 3 TPI or 4 TPI.

Application: Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

Graphite Electrodes&Company

①How about your company?

A world class manufacturer & supplier of Graphite Electrodes is one of the large scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is graphite electrode good for foreign trade?

- Profits can be made for foreign trade. Even if you produce it yourself. Traders take big head. Own production. It's hard for you to play. If you have a client, we can work together

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material. Considering the foreseeable future, the graphite electrode will occupy a high position, usually used equipment for processing graphite electrode the highest efficiency mold manufacturers will unremittingly, expand and between those determined to use the hard steel processing manufacturer competition gap. The foundation of micro cutting tools, in terms of graphite electrodes, is one of its most magical words: "high speed."". The spindle speed of the high speed machining center is up to 30000~60000r/min, and the feed speed can be increased to shorten the processing period and improve the quality of the surface and edge. The motor needed to drive this type of spindle is relatively small and light, which helps to reduce cutting power and reduce tool breakage. This is critical because many of the electrodes are complex, and their production involves small, easily broken micro tools (see Figure 1).

- Q: How to solve the problem of graphite electrode being crushed during electrolysis

- This graphite electrode is so true because it causes gas to expand and disintegrateTantalum electrodes can be solved and not expensive

- Q: The future of graphene

- Sensor domain. Graphene due to its unique two-dimensional structure is widely used in sensor, has the advantages of small size, large surface area, high sensitivity, fast response time, fast and easy electron transfer protein immobilization and maintained its activity and other characteristics, can improve the performance of sensor. Mainly used in the production of gas, biological molecules, enzymes and DNA electrochemical sensors. Singapore Nanyang Technology University developed a graphene light sensor sensitivity is 1000 times the ordinary sensor; the Rensselaer Polytechnic Institute developed performance than the existing commercial gas sensor cheap graphene sponge sensor.

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q: Specification for graphite electrodes commonly used in steel works

- General specification for graphite electrode diameter Phi 300 Phi 500mm, Phi Phi 550 - the current usage of 800mm graphite electrodes is also great, the graphite electrode length was between 1600 and 2700mm.

- Q: What are the losses in graphite electrode?

- So tell, this problem is to answer a lot, graphite under high temperature oxidation, generally around 400 degrees, began a slight oxidation, but the human eye is to be observed, with the increase of temperature, the graphite oxide will increase, this time should be used to protect gas or vacuum to protect what you said is, nitrogen protection, and general protection of nitrogen can reach more than 2000 degrees, if the high temperature to 3800 degrees, will you say that vapor formed in graphite surface. To achieve this temperature, it is necessary to add inert gas to achieve, otherwise, can not reach, generally to 4350 degrees, the graphite began to soften.

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- After energization, electrolysis occurs, not ionizationIonization does not require energization, and can occur in aqueous or molten state.

- Q: What is the difference between SGL graphite electrode and graphite electrode in general?

- Can not say that the more detailed the better, is relative, must be uniform within the range (after all, it is very important to choose the aggregate), such as spectral pure graphite, is not due, he is a lot of technology to producing stains, then burning, and then producing stains, the strength is quite good,

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- The safe current is decided according to the conductor wire cooling conditions, cooling conditions, the overhead line package, an insulating layer and bare, cooling conditions are also different.

Send your message to us

Graphite Electrode With Preset Nipple - RP, HP, UHP for Optimal Electrical Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords