350mm (14 inch) High Quality HD Graphite Electrodes

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

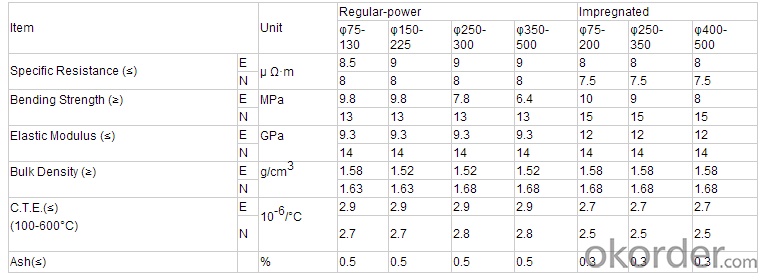

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Electrolytic salt water why use iron as a cathode, all with graphite can not?

- The iron electrode is easier to be installed in the electrolytic cell, which is more convenient than the graphite electrode, and the density of the graphite is small. After being adsorbed by hydrogen, the graphite is easy to float up, and the density of the iron is larger. This problem does not exist in the.5

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- In the electrochemical process, the electrode should not affect the reaction on the working electrode, so platinum and graphite are often chosen

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- Indeed, the original battery electrode potential using two different electrodes, produce potential difference, so that the electron flow generated current. Graphite is used as an electrode because of its excellent electrical conductivity and stability

- Q: How long is the graphite electrode machining cycle?

- When the cut depth is less than 0.2mm, the graphite will break down very little, and the surface quality of the side wall will be better.

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The impact of carbon on the car is quite large, first of all, to reduce the power of the engine, that is, to make the power output uneven and gradually attenuated, in other words, more and more lack of force. Two is to increase fuel consumption, increase your financial burden.

- Q: Graphite graphite graphite graphite electrode what is the use?

- Natural graphite electrode is the main raw material with graphite, high purity flake graphite powder or high carbon flake graphite powder as raw material, because carbon or graphite powder purity is high, the effect of conductive graphite powder is better in smelting alloy steel, iron alloy, electrode graphite powder as raw material. The electrode produced, then the strong current through the melting zone, the arc electrode into the electric furnace, the electrical energy into heat, the temperature rises to 2000 degrees Celsius, so as to achieve the purpose of melting or reaction.

- Q: After vacuum melting of quartz crucible, there are three graphite electrode rods. What's the adjustment?

- The shorter one is the farther away from the other, and the shorter one is the shorter one

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- The energization is the electrolysis of CuCl2 solutions, i.e., redox reactions. So you can't mix ionization and electrolysis.

- Q: Excuse me, why does the graphite electrode flake when electrolyzed salt water is used?

- For example, according to connection of the electrode, which can be divided into two types of unipolar and bipolar type electrolyzer (see photo). The electrode is connected with the DC power supply parallel polarity monopolar electrolyzer, electrodes on both sides of the same, at the same time as anode or cathode. At the same time as the positive and negative electrode bipolar type electrolyzer ends respectively with DC power supply connected, as anode or cathode. The current through the electrode through the electrolysis cell in series, each side of the intermediate electrode as the anode, the other side is the cathode, so it has a bipolar electrode. When the total area at the same time, the current bipolar type electrolyzer is small, high voltage DC power supply, the required investment ratio monopolar, bipolar type filter press used. The general structure, more compact. But easy to leakage and short circuit, slot structure and operation management is more complex than the monopolar type. The monopolar electrolyzer section is generally rectangular or square, cylindrical covers a large, empty The utilization rate is low and the adoption rate is less

- Q: What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

Send your message to us

350mm (14 inch) High Quality HD Graphite Electrodes

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords