Graphite Die Mold Inc Graphite Sintering Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

graphite part:ISO9001

high quality with best price

produce graphite mould as per drawing

supply graphite product stably

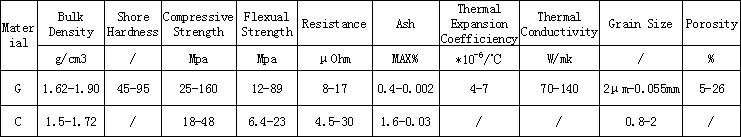

The physical and chemical properties of C and G material:

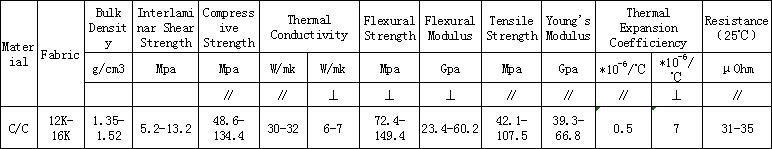

The physical and chemical properties of C/C material:

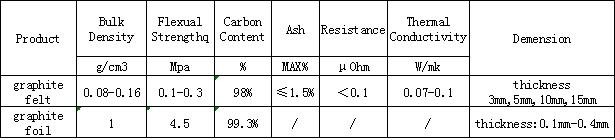

The physical and chemical properties of other material:

Products of carbon and graphite are widely used in such fields as industrial furnaces, mono-crystalline silicon machinery, mono-crystalline silicon machinery, electron, semi-conductor, metallurgy, oil, chemistry, textile, electrical machinery, electrical equipment, electrical furnace, traffic, communication industry, medicine, etc.

Providing graphite heating systems used in mono-crystalline silicon and multi-crystalline silicon industrial furnaces (such as heaters, thermal insulation material, insulation materials, etc.)

Providing graphite moulds, molds, graphite felt, graphite foil, graphite rod, graphite sheet, utensils, crucibles used in furnaces(such as graphite boats ,outer molds, mounting plates, etc.)

Providing graphite crucibles and utensils used for particular amorphous metal, rare metal, and non-ferrous metal and crystallizers for the growth of ferrous metal, etc.

Providing mechanical seal parts, graphite rings, graphite bearings, graphite leaf

Providing carbon felt, carbon cords, graphite power, graphite felt, and compound carbon felt of different specifications

- Q: How is the graphite packing ring made?

- The graphite packing ring is made of a certain density graphite coil, which is mechanically cut into the mold and is made by cold pressing. It has the characteristics of corrosion resistance, high temperature resistance and self lubrication,

- Q: Graphite mold maintenance

- 1. press the punching shear of the mold size, correct use of sufficient tonnage of punch (general machine tool tonnage must be greater than the die punching shear)2. in the mold before the machine, you must check the adjustment of the mold arrow blade gap, in order to transport the loading and unloading of the mold when the blade gap clearance, adjustment can be later on the machine3. molds should clean the upper and lower surfaces of the mold to ensure that the die mounting surface and punch work table pressure, damage to the mold in the production of the upper and lower mounting surface parallelism4 the working surface of the punch and the bottom of the slider must be parallel, the deviation of parallelism should be less than 0.03

- Q: What are the suppliers of mobile 3D glass hot bending graphite die?

- Currently, smartphone heating is a normal phenomenon, this is because most of the smart phones are using high-performance CPU, this year there are many new mobile phones using dual core, quad core, or even eight nuclear CPU.

- Q: We mainly do brass processing, using graphite mold life is too short, please advise

- The longer service life of die material made of, but the price is higher.

- Q: Can graphite electrodes be used in small die making?

- The copper electrode used for finishing size of the copper electrode discharge speed is not fast but spent graphite electrode is relatively small

- Q: Hot work die steel H13, in the process of cooling with graphite milk or water? Is there a crack with water?

- With softening resistance at high temperature, but the temperature is higher than 540 degrees Celsius (1000 degrees Fahrenheit) hardness decreased rapidly (i.e. the ability of working temperature of 540 DEG C);

- Q: What is the die electrode?

- Made of graphite particles is large, suitable for processing, but the price cheaper than copper graphite, light, and easy processing, now fire outside the shop general are carbon industry + electric spark, you pull over to the other die a copy to them, they directly processed graphite shipped back to you electric spark for all to you, the Yang you don't have to go to work there to do the carbon graphite spark.

- Q: Why is Shi Mozhou hollowed out?

- Graphite mold is made of artificial graphite by mechanical processing. Therefore, graphite mold sometimes become a graphite boat, also known as graphite boat.

- Q: What are the differences between domestic and imported graphite? Who can tell me? What are they used in?

- Domestic graphite and imported density is not the same, Shaw hardness is not the same, domestic graphite particles than the import of graphite to be much larger

- Q: Graphite mold, graphite ring and other graphite products, how about anti oxidation coating?

- Some effective antioxidant, take antioxidant coating nano graphite products according to the use conditions of different temperature, can be 1600 degrees, because the nano composite ceramic coating

1. Manufacturer Overview

| Location | Beijing,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 70.00% Domestic Market 10.00% Eastern Europe 10.00% Western Europe 5.00% North America 5.00% Southeast Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | xingang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Graphite Die Mold Inc Graphite Sintering Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches