Gpc143041 Mill Finished Coated Aluminum Square Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Coated Aluminium Square Sheets Description

Mill Finished Coated Aluminium Square Sheets is one semi-finished aluminium material. This sheet can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Coated Aluminium Square Sheets

Mill Finished Coated Aluminium Square Sheets | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Coated Aluminium Square Sheets

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Coated Aluminium Square Sheets

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Coated Aluminium Square Sheets

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

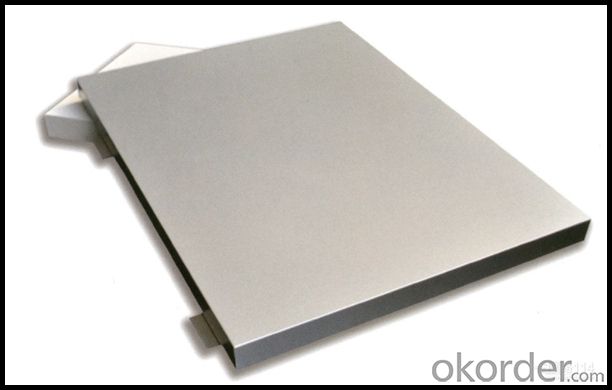

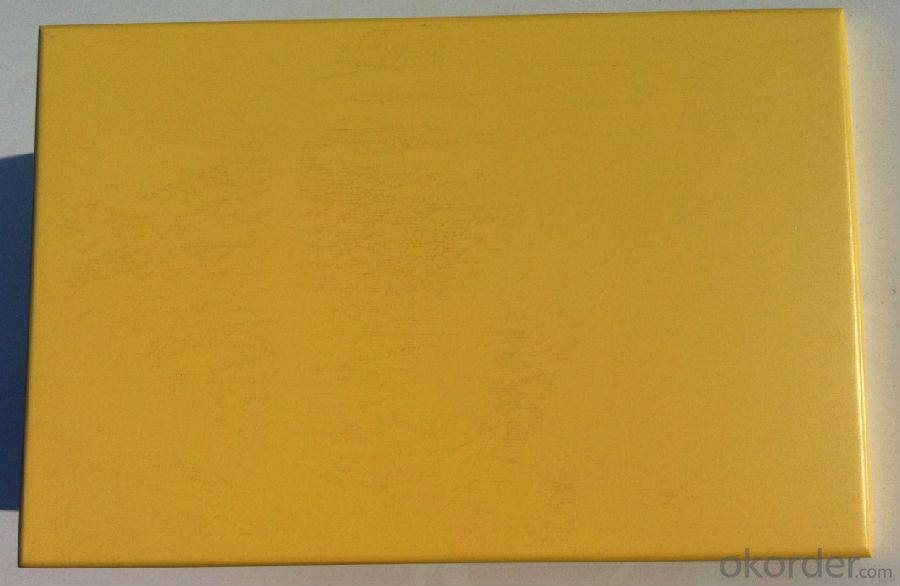

6. Image of Mill Finished Coated Aluminium Square Sheets

7. Package and shipping of Mill Finished Coated Aluminium Square Sheets

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in food processing industries?

- Aluminum coils find applications in the food processing industry. This is because aluminum possesses several advantageous properties that make it a popular choice in this field. It is a lightweight and flexible material with excellent thermal conductivity. These characteristics make it ideal for various uses such as refrigeration, heat exchangers, and ovens in food processing. Moreover, aluminum is non-toxic, resistant to corrosion, and does not affect the taste or odor of the food being processed. Therefore, it is a safe and hygienic option for food processing equipment. Additionally, aluminum coils are easy to clean and maintain, ensuring the highest standards of cleanliness and food safety are upheld. Consequently, due to their outstanding performance and suitability for food-related applications, aluminum coils are widely accepted and utilized in the food processing industry.

- Q: Is it possible to utilize aluminum coils in the construction industry as building materials?

- <p>Yes, aluminum coils can be used for building materials. They are valued for their lightweight, corrosion resistance, and strength. Aluminum coils are commonly used in roofing, siding, window frames, and facades due to their durability and low maintenance requirements. Additionally, they can be easily shaped and recycled, making them an environmentally friendly option in construction.</p>

- Q: Are aluminum coils suitable for marine environments?

- Due to their excellent corrosion resistance properties, aluminum coils are well-suited for use in marine environments. One of the reasons for this is that aluminum naturally develops an oxide layer on its surface, which acts as a protective barrier against saltwater corrosion. Consequently, aluminum coils demonstrate a high level of resistance to rust and deterioration caused by exposure to marine conditions. Furthermore, the lightweight nature of aluminum makes it an ideal choice for marine applications where reducing weight is crucial. Moreover, aluminum coils possess good thermal conductivity, which is advantageous for dissipating heat in marine cooling systems. All in all, aluminum coils are a dependable and durable option for marine environments, guaranteeing long-lasting performance and minimal maintenance needs.

- Q: How much is one square aluminum gate and five hard door?

- On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q: What are the different surface protection options available for aluminum coils?

- Depending on the specific requirements and applications, there are several options available for surface protection on aluminum coils. 1. Applying a paint coating is a common method of surface protection. This creates a protective layer that helps prevent corrosion, oxidation, and damage from environmental factors. Paint coatings also provide aesthetic appeal and come in various colors and finishes. 2. Anodizing is an electrochemical process that creates a durable and corrosion-resistant oxide layer on the aluminum coil's surface. This method enhances the coil's resistance to wear and tear and provides a decorative appearance. Anodized coatings can be clear or colored, offering design flexibility. 3. Another option is applying a protective film made of plastic or vinyl on the surface of the aluminum coil. This film provides temporary protection during transportation, handling, and installation, guarding against scratches and abrasions before being removed. 4. Powder coating involves the electrostatic application of a dry powder onto the aluminum coil's surface. The powder is then cured under heat, resulting in a durable and resilient protective layer. Powder coatings are known for their excellent resistance to chemicals, UV rays, and physical impacts. 5. Cladding, or laminating, involves bonding a protective layer, such as PVC, onto the aluminum coil's surface. This method enhances resistance against scratches, impact, and weathering. Cladding can also provide additional benefits like thermal insulation and noise reduction. When selecting the most suitable surface protection option for aluminum coils, it is important to consider factors such as the intended use, environmental conditions, desired aesthetics, cost, durability, and application requirements.

- Q: What is the typical density of aluminum coils?

- The typical density of aluminum coils is around 2.7 grams per cubic centimeter (g/cm³).

- Q: What are the various techniques used in the manufacturing process to create insulation for aluminum coils?

- <p>Aluminum coil insulation is produced using several methods, including lamination, extrusion, and coating. Lamination involves stacking thin sheets of aluminum with insulating material between them. Extrusion is a process where aluminum and insulation materials are pushed through a die to create a continuous profile. Coating methods apply a layer of insulating material directly onto the aluminum coil surface. These methods ensure the insulation maintains its properties under varying conditions, providing electrical isolation and protection against environmental factors.</p>

- Q: How are aluminum coils used in the production of food processing equipment?

- Due to their desirable characteristics and benefits, aluminum coils are extensively utilized in the manufacturing of food processing equipment. These coils are typically crafted from high-quality aluminum alloy, which offers exceptional heat conductivity, resistance to corrosion, and long-lasting durability. A primary application of aluminum coils in the food processing industry involves their incorporation into heat exchangers. These heat exchangers serve as vital components within various food processing equipment, including ovens, fryers, and refrigeration systems. The aluminum coils housed within these heat exchangers facilitate the efficient and precise transfer of heat between different mediums, ensuring optimal temperature control during food processing. Another significant application of aluminum coils lies in the production of evaporator coils. These coils are essential to the refrigeration systems employed in commercial food processing. By absorbing heat from the surrounding environment and allowing refrigerants to evaporate, the aluminum evaporator coils contribute to the cooling process, thereby maintaining low temperatures within the equipment. Aluminum coils also find utility in the construction of food storage and transportation equipment, such as refrigerated trucks and containers. The lightweight nature of aluminum aids in fuel efficiency and facilitates the easier transportation of food products while preserving their quality and freshness. Moreover, aluminum coils are highly regarded for their hygienic properties and ease of cleaning, making them an excellent choice for food processing equipment. Aluminum surfaces can be easily sanitized, ensuring a high standard of cleanliness and preventing contamination during food production. In summary, aluminum coils play a crucial role in the manufacturing of food processing equipment by providing exceptional heat transfer, corrosion resistance, durability, and hygienic qualities. Their utilization contributes to efficient food processing operations, optimal temperature control, and the maintenance of food quality and safety standards.

- Q: Are aluminum coils suitable for thermal insulation?

- No, aluminum coils are not suitable for thermal insulation. Aluminum is a highly conductive material, meaning it readily transfers heat. This makes it ineffective in preventing heat transfer between different areas or maintaining a desired temperature within a space. For thermal insulation purposes, materials with low thermal conductivity, such as fiberglass, mineral wool, or foam insulation, are preferred as they minimize heat transfer and provide better insulation.

- Q: Can aluminum coils be used for signage and display applications?

- Yes, aluminum coils can be used for signage and display applications. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an ideal choice for various signage and display purposes. Its flexibility allows for easy shaping and customization, while its smooth surface provides a perfect canvas for printing graphics and designs. Additionally, aluminum coils can be easily mounted, making them suitable for both indoor and outdoor signage and displays.

Send your message to us

Gpc143041 Mill Finished Coated Aluminum Square Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords