Glass Wool Pipe Insulation - Good Quality Glass Wool Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool Pipe for thermal Insulation

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

1.Structure of Glass wool Pipe for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and pipes. This product is used as insulation and in other applications, like for air filters.

Raw Materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

2.Main Features of Glass wool pipe for thermal Insulation:

The glass wool pipe is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including pipes, boards and pipes.

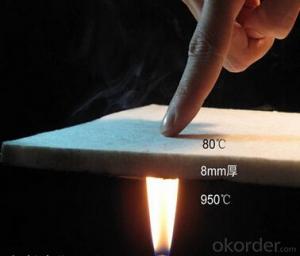

3. Glass wool pipe for thermal Insulation Images

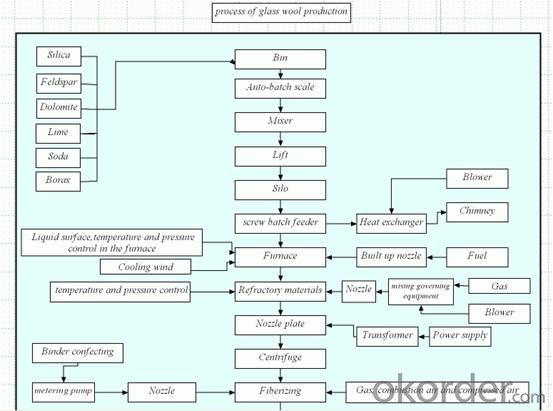

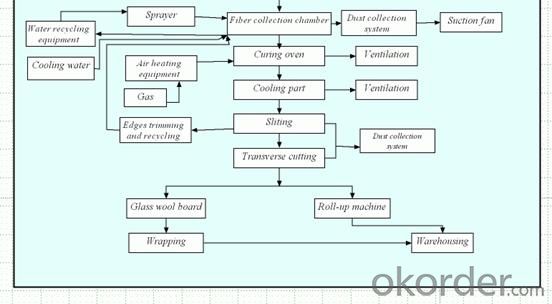

4. Glass wool Processing

5. Glass wool pipe for thermal Insulation Specification

The glass wool pipe is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Both unfaced and faced felts can be provided.

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the difference between imported glass wool and rock wool?

- Glass wool is categorized into glass fiber, which is a manmade inorganic fiber. Glass wool is a material which fibering melting glass to form cottony shape. Its chemical composition belongs to the classification of glass, being an inorganic fiber. So, it is good shaped with small volume density, low thermal conductivity, good thermal insulation and sound absorption properties, great corrosion resistance as well as stable chemical performance. Wish it will help you. Thank you!

- Q: What performance characteristics does aluminium foil ultra-fine glass wool board have?

- 1, It has characteristics of waterproof ability, corrosion resistance, no mildew and no insect, able to prevent condensation effectively and prevent pipes from freezing. 2, It is light in weight, high in sound absorption coefficient, low in thermal conductivity with noninflammability and fire-retardant capability as well as chemical stability. 3, It is low in cost, good in hydrophobic property, good in elasticity and softness, which enables it to be a both commonly used insulation material and commonly used cold retaining material. It has a wide range of applications with stable product performance.

- Q: Who know the construction technology of glass wool?

- I would like to give a brief introduction to the usage of glass wool as the thermal insulation for equipment. 1, Cleaning dust on the surface of equipment. 2, Using adhesive to glue the iron sheet of insulation nails (iron sheet of one square centimeter will be fed in the middle with a slightly harder iron wire of about 8 centimeters) on the surface of the device. Distribution density depends on the weight of glass wool. If insulated cotton is 1 m * 0.5 m, it merely needs to glue seven to eight pieces of iron sheet. When glue of iron sheet finished, the device is like a hedgehog. 3. Once insulation nails sticked firmly, it needs to affix to glass wool, fixing it with a piece of spare iron sheet with a hole in the middle of it (it is round and is a set with insulation nails), and then bend the redundant part of iron wire.

- Q: What is the difference between the glass fiber and glass wool?

- Fiberglass is an excellent inorganic non-metallic material. There are many kinds of glass fibers whose advantages are good insulation, heat resistance, corrosion resistance, high mechanical strength, and the drawbacks are brittle and poor wear resistance. It is made from glass ball or wasted glass through high temperature melting, wire drawing, winding and weaving. The monofilament diameter is between several microns and dozens of microns, the same as 1 / 20-1 / 5 of a human hair. Each bunch of fibre precursor consists of hundreds of or even thousands of monofilaments. Glass fiber is usually used as reinforcing material of composite material, electric insulation material, thermal insulation material, circuit board and various areas. Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability.

- Q: What harm dose glass fiber cotton do to human body?

- We are glad to answer your questions.1 Glass wool damages human health 1 Lots of glass fibers float out during the construction or after the aluminium foil is damaged.The glass fibers may cause serious damage to air quality and human health. According to the lung biopsy for workers who contact glass fiber, there are dust-cell focus, mild hyperplasia of collagen, lung cancer and lung abscess in the lung tissue.People who contact glass fibers may suffer from conjunctivitis and keratitis which will develope into corneal opacity and local abscess when the situation worsens.When the fiber diameter and the length is similiar, the glass fiber can also produce similar toxicity and carcinogenicity with asbestos.2 it is not environmentally friendly and is forbidden to be used in the Olympic venues.In view of the environmental factors, Ministry of Construction and the Beijing Municipal Health Bureau released the relevant documents to regulate the use of glass wool.In line with environmental protection, International Olympic Committee prohibit the use of glass wool in Sydney Olympics and Beijing 2008 Olympic Games.3 it dose not save energy.The aluminum foil covering the glass wool breaks easily. Besides, glass wool has an open cell structure. once it is damaged, water vapor will enter and the wet resistance factor is 0, which means that the insulation effect is reduced, energy is wasted and operating costs increases.

- Q: Can Kunnai glass wool board and sound absorption blankets be used to maintain sound insulation in hotel floor? Can it decrease half of the noise? How to install?

- No, if the amendment of the surface is not good, it will affect the paving of floor and tile. You can select one of these, and you'better use sound insulation felt for it also is waterproof.

- Q: Which is the more commonly used thermal insulation material between thermal insulation glass?silk wool and rock wool?

- Glass wool: Glass wool has no shots, having less dust and little irritation to skin and respiratory system as well as light weight, able to be processed to products with long length based on design requirements. It entails less waste, easy to construction. It uses amorphous cellulose which is soft and lathy with no shots, able to serve for more than 20 years. So, in terms of price per ton, rock wool is cheaper than glass wool. But in terms of price per square meter, the prices of glass wool and rock wool are basically flat. If various factors like effect, construciton, service life, safety and bearing structure are took into account comprehensively, glass wool then is more economical. Rock wool: It contains a high content of shots and much dust. It is high irritable to skin and respiratory system, keeping heavy weight, so it cannot be processed for a long time. It entails much waste, difficult to construction. It uses crystalline fiber, which has a high content of shots, is shoyt and unstable. If used for a certain time, its shots and short?fiber will sink, making it unable to maintain a uniform shape, which will seriously affect the insulation effect and needs to be replaced consequently. And the replacement cycle is shorter than 10 years.

- Q: How to install sound insulation glass wool boards on the wall?

- There is a simple method. First coat a layer of coating on glass wool board or cotton felts.

- Q: Are there any hazards during the glass wool construction?

- Gloves and protective clothing must be put on during the construction, it will be itchy when it touches skin and it will be dangerous when it gets into lungs.

- Q: What are the differences between glass wool and rock wool in terms of thermal insulation?

- If the temperature is higher than 300 degrees, the rock wool boards are better. The operation life of glass wool at high temperature is short, and the price of which is higher than that of rock wool. Galvanized board can be used as protective layer for its long operation life but it rusts easily and is not so beautiful. The aluminium plate has a short operation life and it damages and deforms easily.

Send your message to us

Glass Wool Pipe Insulation - Good Quality Glass Wool Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords