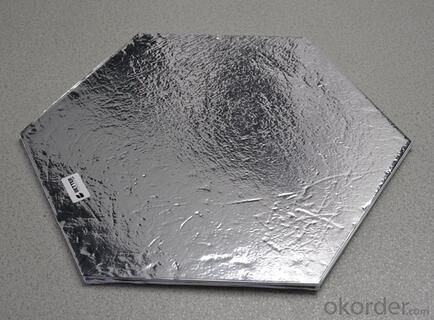

Glass Wool Valuum Insulation Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction:

Product is environment- friendly, energy-efficient insulation. It can be widely used in the field ofexternal wall of building, refrigerator, marine, electromobile, new energy building and other areas.

AB insulation-decorative integrated panels are preformed in the factory, using AB inorganic fi-ber insulation boards or AB inorganic fiber vacuum insulation panels as insulation, using different colors and shapes coating alloy plate or integrally molded polymer mortar panels as exterior panels. It is a new decorative energy-saving system that combines insulating, waterp-roof, decorated.

Superiority:

Decorative surface is diverse and high grade

Product by factory assembly line, safe and secure

Unit insulation and decorating into one, simpler construction, less steps, and shorten the co-nstruction period half more than hanging stone conservation, one-third more than other tradit-ional insulation materials

Labor saving, equipment cost saving, lower total costing

Product in factory,there is not deformation and roughness after the construction

Combined the advantages of the AB insulation boards, having better quality

- Q: Is hyperfine glass fiber cotton different from the centrifugal glass wool?

- Centrifugal glass wool seems to be widely used in construction. Is it harmful to the human body? What is the difference between the centrifugal glass wool and common glass wool? The Centrifugal glass wool is a kind of common glass. Glass wool can be divided into superfine wool and centrifugal glass wool.

- Q: Can mineral wool, rock wool and glass wool thermal insulation be applied to inverted roofs?

- It can be applied and it is just a problem of construction. Some are easier in construction and some are difficult.

- Q: How can I fix the glass cotton insulation board to the wall?

- The method to fix rock wool insulation boards to the wall: Use adhesion agents to bond rock wool and base wall together, and drive insulation supporting pins. Rock wool external thermal insulation uses rock wool board as insulation layer, and set it outside of the structure layer of external wall to achieve thermal insulation effect of wall. This construction method of composite wall insulation material requirements attached to the solid layer structure. The protective layer outside of insulating layer should have a certain intensity, impact resistance, crack resistance and waterproofness, and have good hotel decoration design. Common characteristics of rock wool wall system incluede the increase of thermal insulation properties of external wall, saving energy consumed for heating, the improvement of wall thermal inertia, and of indoor thermal environment. Compared with other energy-saving wall systems, rock wool system is conducive to the discharge of water vapor inside the wall, generating less internal condensation and dewfall, and the structural layer is drier and warmer. Also, the cost of rock wool system is cheap, it has good fire performance, sound insulation performance.

- Q: What are the purposes of centrifugal glass wool?

- Glass wool felts, sound-absorbing cotton felts are an ideal sound absorption and thermal insulation materials which are widely used in walls, ship engine room insulation; computer rooms, cold storages with constant temperature; various generator rooms, pump rooms noise reduction; stereo cabinets, audio adjustments, etc. Function: sound absorption and insulation, as well as thermal insulation of walls.

- Q: Which is more suitable for industrial pipe insulation: glass wool or rock wool ?

- Glass wool, now rock wool seems to be out of date.

- Q: Does glass wool equals to rock wool?

- It mainly used in the thermal insulation of air-conditioning ducts, has coarse fibers. Isover has pink glass wool roll mats. Black soft cotton is rubber and plastic. Rock wool is generally dark and the glass wool is golden.

- Q: What's the heat conductivity coefficient of Kunnai glass wool blanket?

- The particular glass wool in this plant belong to insulation material, which can be calculated. In addition, the heat conductivity coefficient of thermal insulation material has empirical formula, which can be known after detection, so you can refer to the standard DL & # 47

- Q: Glass core material of ultra-fine glass wool

- Glass core material is an important component of VIP, playing an significant role on the heat conductivity coefficient of vacuum insulated panel. Vacuumized core material has certain intensity, which can play a framework supporting role. And the fiber distribution of core material determines the VIP adiabatic degree. Thus, the more uniform the fiber distribution of core material, The lower its heat conductivity coefficient and the better the insulating property.

- Q: What are the industry standards of glass wool and its products?

- Conventions of Quality Management of Enterprises producing Glass Wool and its Products by National Building Materials Bureau Chapter I General Provisions 1. In order to strengthen the quality management of enterprises producing glass wool and its products, and constantly improve quality of products, the cnventions are formulate in accordance to "Product Quality Law of People's Republic of China" and the relevant regulations of the State Council. Associated regulations: 2. Enterprise leaders and workers should continually enhance the awareness of quality and adhere to the development of quality and efficiency, firmly establish the concept of "quality first" and "customer service" and continue to strengthen quality control in the production process to ensure that raw materials, fuel, semi-finished products, finished products and packaging and storage are up to technical standards. Article 2 Enterprises should set advanced, rational and scientific quality principles and objectives. Legal representatives should be in full charge of products quality, and the department of quality management should take full responsibility in management. Distribution of income within the enterprise should be made to link with the quality of work and products, and implement veto of quality. Article 4 Enterprises must strictly enforce product standards, establish and improve the quality system, and implement quality functions combined with the reality of the enterprises in accordance with GB / T19000 a ISO9000 "quality management and quality assurance" series of standards and the provisions of this Regulation. Capable enterprises should draw up "quality Manual", and seriously implement it.

- Q: What's the difference between rock wool board, glass wool board, glass wool felt?

- First question: These three products are used for thermal insulation in roof and wall surface, ship, equipment respectively. Second question: specifications: Rock wool board: 1000 * 630 1000 * 600 1200 * 6001200 * 630 Density is 60-100KG / M3. Imported and exported density is 60-100KG / M3. Glass wool board: 1200 * 600 density: 20-40KG / M3 Glass wool felt : width:1200 density:10-30 [For exoprt] Third question: They can all reach Class A non-combustible. Fourth question: Rock wool board is waterproof and fireproof while glass wool is only fireproof. Fifth question: They can all use tinfoil. Glass wool felt needs to be vacuumized because it has low density. [These are what customers need. ] Sixth question: Add me, and I will inform you the latest changes. Seventh question: It can be used in other ways. Contact me for pecific price.

Send your message to us

Glass Wool Valuum Insulation Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords