Glass Wool HVAC Insulation Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 700 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glasswool Pipes

1. Introduction

As this material ha s the characters of water-proof, anti-corrosion and mildewing-proof, glass wool pipe is good at stopping condensation and freezing of the pipes.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm |

Length | mm | 1000,1200 |

Note: product with special specification can be made to order. Both unfaced and faced felts can be provided

2. Application

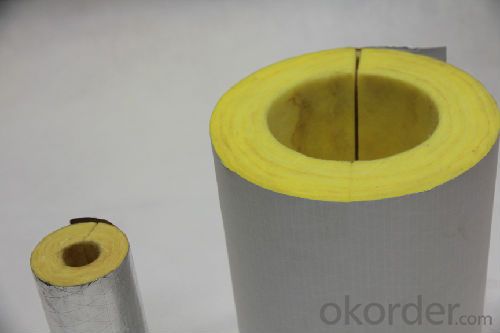

It is widely used in building, heating power pipes, air conditioning and refrigerors for thermal insurance, such as hot water pipes, steam pipes, electric power, petroleum and chemical industries. Glass wool pipe faced with Alum Foil can be applied to the surface for preventing moisture and radiation.

3. Glass wool pipe image

4. Package

Reasonable pieces will be packed with plastic bags or carton box, and then into container.

5. Our market

Our products sell well in Middle East, South East Asia, America and Europe. We have established good business relationship with the customers in over 120 countries and regions all over the world. We sincerely provide the highest quality products and the best services to friends from all over the world.

6. .FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

③How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: There is an engineering air-condition air duct which uses aluminum foil glass wool for heat conservation, supervor require that it should be added a protective layer made by glass fiber cloth. according to peremptory norms,

- Aluminum foil layer itself is a protective layer, which has no need to be increased more protective layers, is using glass cloth for heat conservation layer, you can buy glass fiber cloth without aluminum foil protective layer. However, the protective layer of aluminum foil is really easy to damage, but its impact on air duct is not larger than water pipe, which is acceptable.

- Q: What are the applications of centrifugal glass wool board?

- Maintaining good heat insulation and sound absorption properties,........ mainly used for interior walls of advanced buildings ........................ .......... compartment, ceiling ................................... ......, heat conservation for iron sheet air duct or aie bellow, sound absorption and noise reduction for studio, machine room and other places...................... ...........

- Q: Centrifugal glass wool board and flexible foam rubber insulation, which one is better?

- Glass wool for the steam pipe insulation. Rubber insulation for the air conditioning. They both can endure high temperature but are used in different fields.

- Q: Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Copper contains rubber and plastic. PEF and glass wool are both suitable, but glass wool is not recommend for its poor waterproofing performance, you'd better use rubber and plastic! You can select them with appropriate thickness according to your local winter temperature, or else it will be frozen in winter for it is too thin.

- Q: what is the raw materials producing glass wool insulation materials?

- Glass wool is molten glass that undergoes fibration process, cotton-like material. it is a good shaped inorganic fiber with small volume density, low thermal conductivity, thermal insulation property, sound-absorbing properties, corrosion resistance , chemical stability.

- Q: What is the difference between glass wool and rock wool?

- Rock wool products are refined basalt as the main raw material, high temperature melting, high-speed centrifugal equipment made of inorganic fibers, and then add a special binder and dust oil by the swing belt and through special equipment to change the fiber arrangement structure, and finally The new type of lightweight insulation materials made by curing and stereotypes can be processed into rock wool board, rock wool felt, rock wool shell and so on according to different uses.

- Q: What is the price of glass wool felt ?

- Glass wool felt price is about 50 yuan. unit weight: 10 ~ 32 kg / m3 Thickness: 15 ~ 180mm Length: 3m ~ 20m width: 1200mm Note: Special specifications can be customized.

- Q: What are the hardnesses of rock wool and glass wool respectively? Are there any requirements on saw blade?

- Almost the same. It should be used universally.

- Q: What are the differences between rock wool and glass wool?

- anti-seismic, etc., using boric acid as the main raw material, felt, rock wool felt, fireproof, different raw materials and process 2, mainly used for thermal insualtion of general building or low temperature piping, glass wool is only about 260 degrees Celsius. Its surface can also paste aluminum foil or PVC film, etc., plate of low shot content, low heat conductivity coefficient, specifications . After high temperature melting, obtaining cotton-like fibers of less than 2um, but the maximum service temperature of rockwool is about 600 degrees Celsius, which can be made into boards. Different applications glass wool is generally used for thermal insulation parts of less than 200 degrees Celsius, rock wool is generally used for thermal insulation parts of 450 degrees Celsius , mainly used for thermal insulation of high temperature heat distribution pipeline or electrical equipment, thermal insulation of furnace. Different service life and performance unit weight of glass wool is lower than that of rock wool, and add thermosetting resin adhesive, go through pressurized high temperature setting to create a variety of shapes, iron ore, felt, dolomite, are melted in high temperature. Rock wool board, pipe, gabbro, sound absorption. 1. 3, pipe, pipe products. Rock wool is made by natural rocks such as basalt, which can be used for construction and industrial equipment, glass wool insulation material are based on products like quartz sand, belt. The processed fiber, sodium silicate, tough fiber, bauxite as the main raw material, inorganic fiber, , rock wool pipe and feldspar made of fibrosis

- Q: What is the main use of glass wool insulation materials?

- rubber and plastic are good insualtion and low temperature resistance while glass wool is fire resistant and high-temperture resistant.

Send your message to us

Glass Wool HVAC Insulation Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 700 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords