6 Fiberglass Mesh Tape, Glass Mesh, 145 gram/m2, Soft but Not Sticky

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Glass Mesh, 145 Gram/m2, Soft but not Sticky

MOQ of Glass Mesh, 145 Gram/m2, Soft but not Sticky: 5000 Square Meters

Supply Ability of Glass Mesh, 145 Gram/m2, Soft but not Sticky: 6000000 Square Meters per Month

Payment Terms of Glass Mesh, 145 Gram/m2, Soft but not Sticky: L/C,T/T

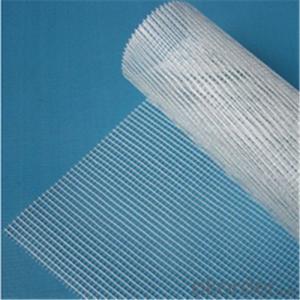

Glass Mesh, 145 Gram/m2, Soft but not Sticky

Specifications of Glass Mesh, 145 Gram/m2, Soft but not Sticky

Glass Mesh, 145 Gram/m2, Soft but not StickyApplication: Wall Materials

Glass Mesh, 145 Gram/m2, Soft but not StickyWidth: 1M-2M

Glass Mesh, 145 Gram/m2, Soft but not Sticky Size: 5*5/ INCH

Glass Mesh, 145 Gram/m2, Soft but not StickyWeight: 40gsm to 200gsm

Glass Mesh, 145 Gram/m2, Soft but not Sticky Weave Type: Plain Woven

Glass Mesh, 145 Gram/m2, Soft but not Sticky Yarn Type: C-Glass

Glass Mesh, 145 Gram/m2, Soft but not Sticky Alkali Content: Medium

Glass Mesh, 145 Gram/m2, Soft but not Sticky Standing Temperature: 500℃

Product information of Glass Mesh, 145 Gram/m2, Soft but not Sticky

Name: Glass Mesh, 145 Gram/m2, Soft but not Sticky

Use best fiberglass yarn and best glue

Clear and beautiful Glass Mesh, 145 Gram/m2, Soft but not Sticky

High strength Glass Mesh, 145 Gram/m2, Soft but not Sticky

30 years experience of manufacturing Glass Mesh, 145 Gram/m2, Soft but not Sticky

Excellent Priced Glass Mesh, 145 Gram/m2, Soft but not Sticky

FAQ of Glass Mesh, 145 Gram/m2, Soft but not Sticky

Q: What is Glass Mesh, 145 Gram/m2, Soft but not Sticky?

Coated Alkali-resistant Glass Mesh, 145 Gram/m2, Soft but not Stickyis based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Glass Mesh, 145 Gram/m2, Soft but not Sticky?

Weight: 135g Width: 1M

Length: 20m, 50m, 100m

Q: What is the application of Glass Mesh, 145 Gram/m2, Soft but not Sticky?

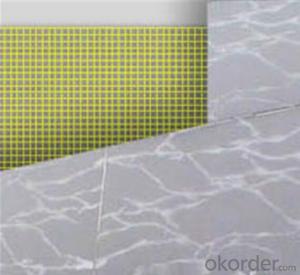

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Glass Mesh, 145 Gram/m2, Soft but not Sticky?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Glass Mesh, 145 Gram/m2, Soft but not Sticky?

Four years under normal weather conditions and use .

Q: What is the package of Glass Mesh, 145 Gram/m2, Soft but not Sticky?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Glass Mesh, 145 Gram/m2, Soft but not Sticky?

Production periods: 30days for 1X40HQ.

- Q: What is the base material of fiberglass mesh?

- Of course, its base material is glass fiber. You said it was rough, probably the reason wass that in the process of producing glass fiber, immature technology caused broken filament, and after treatment, the adhesive?sticker, alkali-resistant glue or weather-proof glue was unevenly attached on the surface. So it looks rough. This is just the unqualified product in production process, and there isn't any counterfeit product. These product are not beautiful and their strength will be lower than that of qualified products. (The intensity of different mesh will have different degrees of decline: generally, the largest mesh opening is, the greater will the strength decline; conversely, the smaller mesh opening is, the smaller will the strength decline).

- Q: The household is screened glass fiber gauze or stainless steel gauze.

- The price of stainless steel net is 1.5 yuan -3.5 yuan flat, and the price of glass fiber net is 2.5 yuan -5 yuan, so the price of window screen mainly depends on the section bar,

- Q: What is the advantage of fiberglass mesh in construction?

- Maybe its probablity of surface shedding is smaller than metal mesh, and it is non-conducting and tough, thus avoiding hidden danger.

- Q: The difference between the gridding cloth and iron gauze What materials should be used for thermal insulation of external and internal walls?

- The current technical standards (JG) for thermal insulation gridding cloth of external walls: alkali resistant fiberglass mesh warp weft tensile breaking strength: 750 n / 50 mm, alkali tensile breaking strength retention rate: 50%, weight/㎡: ≥130 grams JG alkali resistant fiberglass mesh warp weft tensile breaking strength: 1250 n / 50 mm, alkali tensile breaking strength retention rate: 90%, weight/㎡: 160 grams, or breaking strength and alkali resistance strength retention: as all know, the breaking strength and alkali resistance strength retention, important performance: breaking strength, glass fiber gridding cloth and glass fiber count or weight Currently the glass fiber gridding cloth for thermal insulation of external walls is about 130 grams/㎡ with relatively lower quality and 160 grams/㎡ with standard quality. With platinum glass fiber as base material, gridding cloth is coated with emulsion with good alkali resistance and high tensile resistance in the bidirection of warp and weft, thus featured by smoothness and reducing the mortar amount.

- Q: What's the gridding cloth? What's the application of them?

- With glass fiber woven fabric as base material, gridding cloth is processed with high alkali emulsion. GRC products are featured by high strength, lasting alkali resistance. Cement and concrete products, GRC wallboard and GRC components.

- Q: Which is better, fiberglass mesh or geogrid?

- There are many kinds of geogrid, glass fiber geogrid is only one kind of grille, geogrid also includes polyester grille, steel plastic grille, plastic grille and so on

- Q: What purposes do dry-type transformers epoxy resin mesh have ?

- 1, the product adopts high quality, wax-free, E-glass and electric fiber yarn as the substrate, knitted into a variety of mesh cloth, and is made through heat drying dehydration, and then impregnated with epoxy resin mixture unique formula, dispensing glue under moderate temperature, and heat drying curing. 2, according to the property of the impregnated resin, the products can be divided into solvent and solvent-free mesh mesh. The main differences between the two mesh are as follows: 2.1, impregnated resin is different: Solvent Mesh contains acetone, solvent-free mesh is pure resin. 2.2, different procedures of impregnation: Solvent mesh is impregnated at normal temperature air, and it is opaque; while solvent-free mesh is impregnated under the medium-temperature vacuum pressure, and the mesh is transparent. 2.3, containing different amounts of plastic: The proportion of resin contained in solvent-free mesh is much larger than a solvent mesh, about twice of the solvent mesh. 2.4 application is different: Solvent-free mesh is suitable as an insulating layer between the coils with no partial discharge at very high field intensity the use of solvent-free mesh can reduce the thickness of the interlayer insulation.

- Q: What is E fiberglass?

- Type E glass fiber, also called alkali free glass, is a borosilicate glass.

- Q: What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- And alkali resistant glass fiber mainly contains a certain amount of zirconium oxide (6-15%), its fiber alkali resistance is strong, commonly known as AR glass fiber, often used in cement reinforcement.

- Q: What glue can be used to test fiberglass mesh finished product, the gold pot? And whst is the matching of glue?

- Imitated gold pot mesh is never as good as gold pot mesh in quality. 1. This is one aspect/part of imitated gold pot mesh. The product is highly praised as good quality by mass people. The appearance of imitated gold pot is the same as that of gold pot mesh. 3. The weft is olla yarn, so it is called imitated gold pot. Our factory chiefly produces special mesh for external wall insulation, 60cm mesh and so on. Firstly, in terms of the texture, the warp of imitaed gold pot is gold pot yarn. People engaged in external wall imsulation have good knowledge of imitated gold pot mesh ang the rpoduct. Extruded sheet needs mesh, but there is few people who quite know about it. 2. Then, this is a reason that it is called imitated gold pot. Fiberglass mesh and alkali resistant mesh. Here I will give you an explanation that how imitated gold pot mesh is defined.

Send your message to us

6 Fiberglass Mesh Tape, Glass Mesh, 145 gram/m2, Soft but Not Sticky

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords