Sticky Fiberglass Mesh for Construction Resistant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Wall Mesh for Construstion Material

Product Description

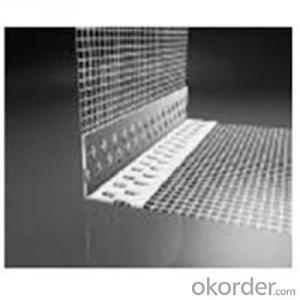

Fiberglass wall mesh Made of C or E glass fiber yarn through special weaving technique,

then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing.

It is ideal engineering material in construction and decoration industry!

fiberglass wall mesh High Quality

1. Coating glue: our coating glue is produced by Germany BASF which can keep more than 70% after 28 days NaoH test.

2. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it is more 20% strong strength and beauty surface than normal fiberglass yarn.

fiberglass wall mesh Application

1.Fiberglass wall mesh is Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board, bitumen)

2. Reinforced cement products.

3. Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

Certificates to guarantee quality.

Passed in ISO9001:2000 certificate , IQ net, China National test, ROSH,Europe ETAG certificate

Company information :

Advantage:

1.CNBM International is a subsidiary of the CNBM Group

2.The largest building materials and equipment group in China

3.Government owned compny

4.Owned our logistics parkand in Dubai

Our service :

1.Any time you can contact with us

2.Free sample

3.If you place order ,we will update the new production process to you

4.Every order,we will make professtional inspecting

5.If you have any feedback , we will first time to make it for you

6.We will all stand your side to consider everything

Fiberglass wall mesh Payment:

T/T 30% in advance, T/T 70% against B/L copy.

FAQ:

Q: What are we doing?

A: we offer the best fiberglass mesh with the right price, we make the best ones , and also offer sourcing service for many products

Q: What are we making in our own factory?

A: we are one of the best fiberglass mesh supplier in China. We own and co-own the best fiberglass mesh factory, and we also make many accessories in our own factory, So we have many exclusive products that is only available from us.

Q: How is our customer service?

A: All our sales representatives can speak fluent English. They will answer all of your questions within 24 hours.

Q: What others can we offer?

A: Based on the wide products range, we offer the best one-step sourcing services. We will definitely save you a lot of time and money, and based on our quantity of shipment, we can get the best shipping service from the best forwarders. This will help you to save a lot on shipment.

- Q: Can wall bricks be pasted on the indoor glass fiber gridding cloth?

- Yes. Glass fiber gridding cloth is used for roofing waterproofing and wall or board reinforcement such as gypsum and mosaics.

- Q: To prevent painting wall from cracking, is fiber glass cloth or mesh better?

- Glass fiber cloth is better in effect.

- Q: The difference between glass fiber and plastic fiber screen

- You say that the chemical fiber adsorption should refer to electrostatic adsorption, rather than activated carbon adsorption! The chemical fiber filter screen has no adsorption to the odor! The fiber diameter and pore size of the glass fiber filter screen are much smaller than that of the chemical fiber! The two can produce bacteria, but the bacteria in the fiberglass can not pass through the screen (the bacteria on the wind side can fly out, but they will also be blocked on the screen later).

- Q: Glass fiber gridding cloth is easy to be broken after being glued.

- It depends on the glues.

- Q: What's the gridding cloth? What's the application of them?

- With glass fiber woven fabric as base material, gridding cloth is processed with high alkali emulsion. GRC products are featured by high strength, lasting alkali resistance. Cement and concrete products, GRC wallboard and GRC components.

- Q: What's the use of glass fiber cloth? What are the main trades?

- Building for external wall insulation layer, glass fiber industry is also useful glass fiber cloth. The main function is to increase the strength

- Q: When external wall thermal insulation Mesh use fiberglass mesh not less than 290 g /m 2 , is it avaliable to stick tile? Is there no specific technical specifications or procedures to support?

- As far as I know, heat retaining exterior wall tile must hang galvanized welded wire mesh to strengthen, you can refer to jgj144-2004, many provinces follow this operation, I did not see specification supports tiling with Mesh.

- Q: What's the application of glass fiber gridding cloth?

- Glass fiber gridding cloth used for pasting wall before scraping putty is a decoration material used for wall crack with good effect.

- Q: When the wall plastering, can use galvanized steel mesh instead of alkali glass fiber mesh cloth?

- It's too expensive. It's wasteful and bad to handle.

- Q: Should the wall be pasted with gridding cloth before painting?

- If there is obvious crack on the wall, gridding cloth should be pasted on the wall and the crack should be bonded.

Send your message to us

Sticky Fiberglass Mesh for Construction Resistant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords