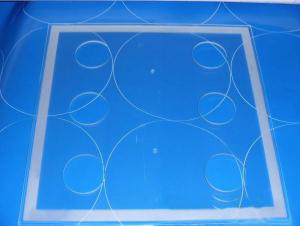

Glass hot stamping foil4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

With current technology, aluminum-plastic plate pattern is plated through polymer film, but this process frequently creates air bubbles, rendering the material unusable. Through new technology launched by our company, we use thin film coating, a special gravure printing technique, to print the customer’s required patterns and visual effects on a thin film of PET. The pattern is then transferred directly to the aluminum plastic plate with the use of high temperature (150℃). Our company’s products feature an increased UV protective coating on the transfer film, making the aluminum plate more resistant to physical scratching and chemical corrosion.

- Q: Plastic pad hot stamping how to deal with?

- Causes and treatment methods of plastic products stamping failuresCauses and Countermeasures of hot stamping failures, fault names, causes and CountermeasuresHot stamping layer and substrate combination is not firm, easy to peel

- Q: Hot stamping materials

- The first layer is the base film layer, also known as the film base, which supports the role of other layers, the thickness of 12, 16, 18, 20, 25 polyester film or polyester.The second layer is the isolation layer (separation layer), which is convenient for the separation of the basement membrane and the anodized aluminum foil during hot stamping.The third layer is the dyeing layer (protective layer): provide a variety of color effects, while protecting the aluminum layer.The fourth layer is aluminized layer: reflecting light, showing metallic luster, adopting vacuum aluminium plating method. The specific principle is coated with color film, in a vacuum vacuum continuous aluminium in indoor machine, in a certain vacuum, by resistance heating, aluminum wire melting and continuous evaporation into the film layer, formed the aluminized layer.

- Q: What's the reason for the lack of stamping or stamping?

- Printing printing ink layer too thick: color ink layer thick substrate, the substrate surface will prevent the adsorption of aluminum foil stamping of the adhesive, the foil adhesion decreased, resulting in hot stamping or not.

- Q: What is the working principle of the gilding press?

- Introduction to the working principle and classification of gilding pressThe principle is to have the color of gilding bronzing paper bronzing paper to cover your substrate through the above pressure, time adjustment, glue layer its subsequent stamping paper through temperature and pressure to combine with the substrate, and then through the foil layer and the base layer and some from each other from the rest the glue layer, plating layer, color layer used in your substrate to the above.

- Q: What is the principle of anodized aluminum printing of different colors of aluminum layer to the surface of printed matter?

- Physical action, pressure and temperature, anodized aluminum on paper or film

- Q: What is the structure of anodized aluminium foil?

- Anodized aluminum foil usually consists of five layers of different materials

- Q: What's the use of hot stamping paper?

- With the rapid development of stamping foil and packaging industry, the application of anodized aluminum is more and more widely. Such as: book cover bronzing, gift boxes, wine, bronzing, smoke clothing trademarks and box bronzing, greeting card, invitation cards, pen bronzing etc., its color and pattern, also can be customized according to the specific requirements of zhuanban. Hot stamping of the substrate, including general paper, gold, silver, ink and other printing ink, printing paper, plastics (PE, PP, PVC, engineering plastics, such as ABS), leather, wood and other special materials.

- Q: How many anodized aluminum foils does a standard volume of anodized aluminum foil require?

- Also known as gilt paper, in the early 1930s, the Germans used the gold vacuum attached to the wax coated glass paper method, the first time produced gold foil

- Q: UV printing can also be hot stamping

- Although the UV light oil high light effect unique to allow the majority of printing professionals recognized, but the light oil can not meet the requirements of performance in finishing the light oil due to the printing adaptability is not mature enough, the printing quality is not stable. A more important reason is that the resin composition and additives in UV varnish are not suitable for hot stamping. These problems need to be solved by UV light oil manufacturers.

Send your message to us

Glass hot stamping foil4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords