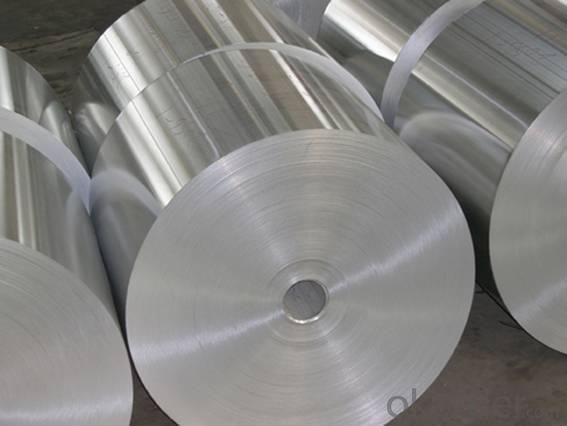

High Quality Aluminium foil Coil Aluminium Container

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Material: PET/AL/NY/PE, PET/NY/PE, PA/PE as clients' required and with custom thickness.

2)variety sizes: 20cmX15m, 28cmx6.5m for rolls, and 10x14 inch, 13.5x20inch, 8x12 inch for bags or customized sizes.

3) All colors are available: Up to 12 colors and can be custom-made, plate cost is based on their sizes and artworks (AI, or PDF, EPS formats are faster and clearer to do plates, JPG File over 300kb also is good for us).

4) MOQ: 10,000 pcs, production time is 10-12 days. Stock bags could be in a very lower quantity.

5) Type: 3 side seal bags, ziplock bags, stand up bags, rolls

6) Feature:

a Strong sealing, High tensile strength, good carrying capacity.

b All materials are eco-friendly.

c Glossy printing, sharp color, durable print

d Easy opening with reclosable zipper

e Cost effective

f nnovative design to enhance marketability and visibility

g With E holes or round holes to make cosmetic bags hanging easily

h Recyclable (Bio degradable)

7) Applications:

a Solid Contents for Foods: Candy, Biscuit, Potato Cracker, Spice, Soup Powder, Vegetable, Chocolate, Jerky, Pet Foods, Croutons, and more

b Solid Contents for Cosmetic and Washing Powder and Other Industry Use: Washing Powder, Lawn Weed Control Granule, Meadow Grass Mixture, Ant-killer Granule, and more

c Dried Foods: Potato Chip, Raisin, Snack, and more

d Liquid Contents: Juice, Drink, Mineral Water, Sauce, Ketchup, Milk, Skin Care, Soap Liquid, Detergent, Paste, Cream, Tea, Coffee, Shampoo, Edible Oil, and more

8) Producing process: Mould/Cylinders making, printing, laminating, separating and cutting, bag making, inspection, packing in cardboard box

9)Samples are available: finished similar samples or do samples in clients’ specification about 8-10 days

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT).

- Q: Plastic pad hot stamping how to deal with?

- (1) the foil binder does not match the material of the base material. Variety of foil should be replaced.(2) the surface of the product has mould release agent, grinding agent, dust, fingerprint and oil stain. Should use alcohol and other solvents to wipe the surface of the product.(3) the stamping temperature is too low. Should be appropriately improved.(4) the stamping pressure is too small. Should be appropriately improved.(5) the stamping time is too short. Should be appropriately extended.(6) the foil is out of date and the adhesive is invalid. New foil shall be replaced and overdue foil shall not be used.(7) the surface of the hot stamping face has reinforcing ribs or other highly different structures, resulting in uneven stamping pressure.

- Q: Hot stamping materials

- According to material types can be divided into: anodized aluminum stamping, foil stamping, film stamping, metal foil stamping and other hot stamping foil. The key to introduce the hot stamping anodized aluminum materials, aluminum foil is a film based on the vacuum evaporation a layer of metal foil made of hot stamping material.

- Q: What's the reason for the lack of stamping or stamping?

- Choice of anodized aluminum foil is not suitable for substrate, or affect the fastness of hot stamping.Stamping temperature is too low or too low pressure.

- Q: What is the working principle of the gilding press?

- At present, the gilding machine, which can be seen in the domestic and foreign markets, is used in the processing of paper products. It can be classified into three categories: flat, round, flat and round. The flat stamping machine, representative brand: Bost, Swiss cheese, Swiss domestic, Yutian, china. Hot stamping machine is the most popular flat stamping model, the most commonly used manual stamping machine also belongs to flat stamping machine. Circular hot stamping machine, representative brand: Germany Steuer foiljet, as well as for other brands and supporting the rotary printing machine. The above bronzing process has its own characteristics, can not simply say that some kind of process is better than other techniques, users should consider their actual production situation, adopt the appropriate process, choose the appropriate equipment.

- Q: What is the principle of anodized aluminum printing of different colors of aluminum layer to the surface of printed matter?

- Anodized hot stamping process are as follows: through hot stamping anodized aluminum version makes the heating, melting and stripping layer, adhesive layer is melted in nano imprint lithography adhesive layer and substrate bonding, the colored layer and the polyester film base from the aluminizing layer and the coloring layer in the substrate.

- Q: What is the structure of anodized aluminium foil?

- From the opposite to the front substrate, followed by the isolation layer (also called stripping layer), protective layer (also called the colored layer), aluminium layer and adhesive layer.

- Q: What's the use of hot stamping paper?

- With the rapid development of stamping foil and packaging industry, the application of anodized aluminum is more and more widely. Such as: book cover bronzing, gift boxes, wine, bronzing, smoke clothing trademarks and box bronzing, greeting card, invitation cards, pen bronzing etc., its color and pattern, also can be customized according to the specific requirements of zhuanban. Hot stamping of the substrate, including general paper, gold, silver, ink and other printing ink, printing paper, plastics (PE, PP, PVC, engineering plastics, such as ABS), leather, wood and other special materials.

- Q: How many anodized aluminum foils does a standard volume of anodized aluminum foil require?

- Also known as gilt paper, in the early 1930s, the Germans used the gold vacuum attached to the wax coated glass paper method, the first time produced gold foil

- Q: UV printing can also be hot stamping

- Although the UV light oil high light effect unique to allow the majority of printing professionals recognized, but the light oil can not meet the requirements of performance in finishing the light oil due to the printing adaptability is not mature enough, the printing quality is not stable. A more important reason is that the resin composition and additives in UV varnish are not suitable for hot stamping. These problems need to be solved by UV light oil manufacturers.

Send your message to us

High Quality Aluminium foil Coil Aluminium Container

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches