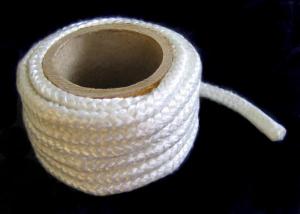

Glass Fiber Textiles Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General info of Textured Fiberglass Round Braided

1. Fire fiberglass rope is made of continuous filament texturized C or E glass yarns and is extremely strong, resilient, and flexible.

2. Fire fiberglass rope are asbestos free, cause no harm to health, making them ideal replacements to asbestos ones.

3. For higher loads, the round braided and square braided ropes can be reinforced by steel wires.

4. Fire fiberglass rope also can be coated with graphite or vermiculite to increase thermal insulation and abrasive resistance.

Fire Fiberglass Rope Application:

1. Fire fiberglass rope are widely used as gasket for industrial ovens and furnaces, boilers and wood burning stoves.

Specifications of Textured Fiberglass Round Braided

1. Fire Fiberglass Rope 2. Round braided or square braided 3. Temperature: 450C-550C 4. Thickness:3mm-100mm

- Q: What are the main ingredients of optical fiber?

- The main raw material of optical fiber fiber, according to the composition of raw materials, inorganic and organic types, inorganic materials have high-purity quartz, organic raw materials have polystyrene, PS, polymethyl methacrylate, PMMA and so on.

- Q: The antibacterial effect of bamboo fiber fabric is because it has been added with a kind of assistant, not the yarn of bamboo fiber itself

- Natural bamboo fiber fabric is not without, but it is difficult to extract natural bamboo fiber, the cost is very high, so either expensive or less content of poor

- Q: How do glass fiber textiles contribute to moisture resistance?

- Glass fiber textiles contribute to moisture resistance through their inherent properties. Glass fibers are made from a non-absorbent material, meaning they do not readily soak up or retain moisture. This helps to prevent water from seeping through the textile and reaching the underlying materials or surfaces. Additionally, glass fiber textiles are often woven or knitted into a tight and dense structure, which creates a barrier against moisture. The interlocking fibers form a physical barrier that prevents water molecules from passing through, thereby enhancing the moisture resistance of the textile. Moreover, glass fibers are highly resistant to mold and mildew growth, which can be triggered by moisture. This resistance is due to the inorganic nature of glass fibers, as mold and mildew typically thrive on organic materials. By inhibiting the growth of these microorganisms, glass fiber textiles help to maintain a dry and moisture-free environment. Furthermore, glass fiber textiles can be treated with water-repellent coatings or finishes to enhance their moisture resistance. These coatings create a hydrophobic surface, causing water to bead up and roll off the textile rather than being absorbed. This additional layer of protection further improves the moisture resistance of glass fiber textiles. In summary, glass fiber textiles contribute to moisture resistance through their non-absorbent nature, dense structure, resistance to mold and mildew, and the potential for water-repellent coatings. These properties make glass fiber textiles an excellent choice for applications where moisture resistance is crucial, such as in outdoor clothing, upholstery, or building materials.

- Q: Are glass fiber textiles resistant to warping?

- Yes, glass fiber textiles are resistant to warping. Glass fiber textiles are made from fine strands of glass that are woven together to form a strong and flexible fabric. The glass fibers have high tensile strength and low thermal expansion, which makes them highly resistant to warping. This means that even when exposed to high temperatures or pressure, glass fiber textiles maintain their shape and integrity. Additionally, glass fiber textiles are also resistant to moisture, chemicals, and UV radiation, further enhancing their ability to resist warping. Overall, glass fiber textiles are known for their dimensional stability and are widely used in applications where warping is a concern, such as in the aerospace, automotive, and construction industries.

- Q: What are the different coating options for glass fiber textile?

- There are several coating options for glass fiber textiles, including polyurethane, acrylic, silicone, and fluoropolymer coatings. Each coating offers different properties such as water resistance, UV resistance, heat resistance, and abrasion resistance, allowing the glass fiber textile to be used in various applications such as protective clothing, tents, awnings, and industrial materials.

- Q: Can glass fiber textiles be used in reinforcement of basalt fibers?

- Yes, glass fiber textiles can be used in reinforcement of basalt fibers. Glass fiber textiles are known for their high strength and stiffness, which makes them suitable for reinforcement applications. Basalt fibers, on the other hand, have excellent resistance to high temperatures and chemical corrosion. By combining the two materials, the resulting composite can have a unique combination of properties such as high strength, high temperature resistance, and improved durability. This makes glass fiber textiles a viable option for reinforcing basalt fibers in various applications, such as construction, automotive, and aerospace industries.

- Q: Can glass fiber textile be used in solar panel applications?

- Yes, glass fiber textile can be used in solar panel applications. Glass fiber textiles are lightweight, flexible, and have excellent thermal and electrical insulation properties. These characteristics make them suitable for use as a substrate material in solar panels. Glass fiber textiles can be used as a backing material for solar cells, providing structural support and protection. Additionally, they can be laminated with other materials to enhance the performance and durability of the solar panels. Overall, glass fiber textiles offer a cost-effective and environmentally friendly solution for incorporating solar panels into various applications.

- Q: How do glass fiber textiles compare to synthetic fiber textiles?

- Glass fiber textiles and synthetic fiber textiles differ in their characteristics. Glass fiber textiles are created by weaving or knitting fine strands of glass to form a fabric. They are renowned for their strength, durability, and resistance to heat and chemicals. Additionally, they exhibit exceptional dimensional stability, ensuring they do not easily stretch or shrink. These qualities make glass fiber textiles ideal for applications demanding high tensile strength, stability, and resistance, such as in the automotive and aerospace industries. In contrast, synthetic fiber textiles are composed of man-made fibers like polyester, nylon, or acrylic. These materials mimic the properties of natural fibers, such as silk or cotton, but offer additional advantages. Synthetic fiber textiles are typically lightweight, low-maintenance, and resistant to wrinkling and shrinking. They also possess moisture-wicking properties, making them suitable for sportswear and outdoor gear. Furthermore, synthetic fibers can be engineered to possess specific attributes, such as flame resistance or UV protection. When comparing glass fiber textiles to synthetic fiber textiles, one must consider the intended purpose and desired features. Glass fiber textiles excel in applications requiring strength, dimensional stability, and resistance to heat and chemicals. On the other hand, synthetic fiber textiles are more versatile and can be customized to meet specific requirements, such as moisture management or comfort. Ultimately, the choice between these two types of textiles depends on the specific needs of the application at hand.

- Q: Are glass fiber textiles suitable for electrical applications?

- Yes, glass fiber textiles are suitable for electrical applications. Glass fiber textiles, also known as fiberglass textiles, have excellent electrical insulation properties due to the high dielectric strength of glass fibers. This makes them ideal for use in electrical insulation applications where high voltage or electrical current is present. Glass fiber textiles are commonly used in electrical equipment such as transformers, motors, generators, and power cables to provide insulation and prevent electrical leakage or short circuits. Additionally, glass fiber textiles have good resistance to heat and fire, which further enhances their suitability for electrical applications. Overall, the unique properties of glass fiber textiles make them a reliable and effective choice for various electrical applications.

- Q: What are the different types of glass fiber textile?

- There are several different types of glass fiber textiles available in the market, each with its own unique characteristics and applications. Some of the most common types include: 1. Glass Fiber Fabrics: These are lightweight and flexible fabrics made from glass fiber yarns. They are commonly used in applications such as aerospace, automotive, and marine industries, where high strength and heat resistance are required. 2. Glass Fiber Roving: Roving is a continuous strand of glass fibers that is used for filament winding, pultrusion, and other composite manufacturing processes. It is typically used in the production of structural components such as pipes, tanks, and beams. 3. Glass Fiber Mats: Glass fiber mats are non-woven fabrics made from randomly oriented glass fibers. They are commonly used in applications where high strength, thermal insulation, and sound absorption are necessary, such as in the construction industry. 4. Glass Fiber Tapes: Glass fiber tapes are narrow strips of woven or non-woven glass fibers. They are often used for reinforcing joints, repairing cracks, and providing additional strength to various structures. 5. Glass Fiber Yarns: Glass fiber yarns are twisted strands of glass fibers. They are commonly used in applications such as weaving, knitting, and braiding to produce fabrics with specific properties, such as high tensile strength and dimensional stability. 6. Glass Fiber Ropes: Glass fiber ropes are made by twisting multiple glass fiber yarns together. They are widely used for applications requiring high strength, such as in the construction of suspension bridges and power transmission lines. Each type of glass fiber textile offers unique properties and advantages depending on the specific application. It is important to consider factors such as strength, flexibility, thermal resistance, and cost when selecting the appropriate type of glass fiber textile for a particular project.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Glass Fiber Textiles Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords