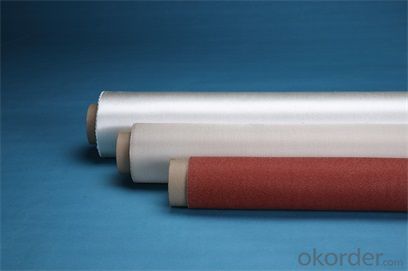

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Silica fiberglass is inorganic fiber that contents more than 96% of SiO2, it's resistant to high temperature, soft point 1700°C, long term service temperature 900 °C, it can work 10 minites at 1450 °C and keeps good state at 1600 °C for 15 seconds. For it's properties of chemical stability, high temperature resistance and ablation resistance, it widely used in aviationand aerospace, metallurgy, chemical, building material and fire fighting industry, etc.

Our factory is the only one that specialized manufacture silica fiberglass in China and has the production line of the whole process from marble making, fiber forming, weaving, and finish. The strength of silica fiberglass made from Na2O-B2O3-SiO2 system glass is 3-5 times higher than that from E glass. The products sold to more than 20 provinces, cities, autonomous regions and exported to foreign countries.

Silica fiberglass products are available in forms of needled mat, fabric, scrim, staple yarn, chopped strand and cord, etc.

Product Properties

1> SiO2>=96%

2> soft point nearly 1700°C, long-time working at 900°C

3> low thermal conductivity

4> good chemical stability

5> good electrical insulation

6> low thermal shrinkage

7> Non-asbestos product without pollution

8> good process performance

Product Uses

High temperature resistant, insulation and sealing material

High temperature ablation resistant material

Fireproof material (for fireproof protective clothe, fireproof curtain, fire blanket)

Dust collecting in media of high temperature gas and filtration in media of high temperature liquid

Filter for molten metal

Distinguisher, insulation material, filtration of automobile and motorcycle

Protective material for welding

Electricity insulation material

- Q: Can glass fiber textiles be used in footwear?

- Yes, glass fiber textiles can be used in footwear. They are commonly used in shoe manufacturing to add strength, durability, and support to the footwear. Glass fiber textiles provide excellent resistance to abrasion and can enhance the overall performance and longevity of the shoes.

- Q: Can glass fiber textiles be used in upholstery and home decor?

- Yes, glass fiber textiles can be used in upholstery and home decor. They are known for their durability, resistance to stains and fading, and fire-retardant properties, making them suitable for various applications such as furniture upholstery, curtains, rugs, and wall coverings. Additionally, glass fiber textiles can provide a modern and sleek aesthetic to home decor while offering practical benefits.

- Q: How does glass fiber textile perform in terms of UV resistance?

- Glass fiber textile typically has excellent UV resistance. Due to its inherent properties, it is highly resistant to the damaging effects of ultraviolet radiation, making it a durable and long-lasting material for outdoor applications.

- Q: What are the different finishes available for glass fiber textiles?

- There are several different finishes available for glass fiber textiles, each with its own unique properties and applications. Some of the most common finishes include: 1. Sizing: Sizing is a finish that is applied to glass fiber textiles to improve their handling and processing characteristics. It helps to reduce the fiber-to-fiber friction, making it easier to handle and weave the textile. Sizing also provides temporary protection against abrasion and mechanical damage during processing. 2. Silane Finish: Silane is a chemical compound that is commonly used as a finish for glass fiber textiles. It helps to improve the adhesion between the glass fibers and the matrix material in composite applications. Silane finishes also enhance the wetting properties of the fibers, allowing for better impregnation of the resin during composite processing. 3. Anti-static Finish: An anti-static finish is applied to glass fiber textiles to reduce or eliminate the buildup of static electricity. This is important in applications where static electricity can cause problems, such as in the manufacturing of electronic components or in cleanrooms. 4. Fire-resistant Finish: Glass fiber textiles can be treated with fire-resistant finishes to improve their resistance to flame and heat. These finishes can provide added safety in applications where fire hazards are present, such as in the construction industry or in protective clothing. 5. Water-repellent Finish: A water-repellent finish can be applied to glass fiber textiles to make them resistant to water absorption. This helps to prevent the textile from becoming heavy and wet, which can affect its performance and durability. 6. UV-resistant Finish: Glass fiber textiles can be treated with UV-resistant finishes to protect them from the damaging effects of sunlight. These finishes help to prevent the degradation of the fibers and extend the lifespan of the textile, making it suitable for outdoor applications. It is important to note that different finishes can be combined to achieve specific performance requirements. For example, a glass fiber textile may have a silane finish for improved adhesion in composite applications, as well as a fire-resistant finish for added safety. The choice of finish will depend on the intended application and the desired properties of the textile.

- Q: Can glass fiber textile be used in automotive exteriors?

- Glass fiber textile, also known as fiberglass, has the capability to be utilized in automotive exteriors. This versatile material is commonly employed in various industries, including the automotive sector. It possesses several advantageous qualities, such as high strength, lightweight nature, resistance to corrosion, and thermal insulation properties. Consequently, it is highly suitable for incorporation into automotive exteriors. The integration of glass fiber textile into composite materials utilized in automotive exteriors, such as body panels, hoods, roofs, and bumpers, allows for reinforcement and enhancement of their structural integrity and durability. Furthermore, fiberglass's exceptional strength-to-weight ratio aids in reducing the overall weight of the vehicle, thereby leading to improved fuel efficiency and performance. Moreover, glass fiber textiles can be molded into intricate shapes, enabling greater design flexibility. This feature empowers automotive designers to create sleek and aerodynamic exteriors while simultaneously adhering to the necessary strength and safety standards. Additionally, fiberglass possesses resistance to corrosion, which is particularly advantageous for automotive exteriors that are exposed to diverse weather conditions, road debris, and chemicals. Furthermore, it provides thermal insulation, decreasing heat transfer and enhancing the overall comfort of the vehicle. To conclude, due to its strength, lightweight nature, resistance to corrosion, thermal insulation properties, and design flexibility, glass fiber textile can indeed be employed in automotive exteriors. Its utilization in composite materials for body panels, hoods, roofs, and bumpers offers numerous benefits, including improved structural integrity, reduced weight, enhanced fuel efficiency, and resistance to corrosion.

- Q: Can glass fiber textiles be used in wind turbine blades?

- Yes, glass fiber textiles can be used in wind turbine blades. Glass fiber is a commonly used material in the manufacturing of wind turbine blades due to its excellent strength-to-weight ratio and durability. It is made by weaving glass fibers together to create a textile-like material that is then impregnated with a resin matrix to provide structural integrity. These textiles offer several advantages for wind turbine blades, including high tensile strength, stiffness, and resistance to fatigue and corrosion. Additionally, glass fiber textiles can be easily molded into complex shapes, allowing for the production of aerodynamically efficient blade designs. Overall, glass fiber textiles are a suitable and widely used material in the construction of wind turbine blades.

- Q: Can glass fiber textiles be used in reinforcement of resins?

- Yes, glass fiber textiles can be used in the reinforcement of resins. Glass fiber textiles, also known as fiberglass, are commonly used as a reinforcing material in industries such as automotive, aerospace, construction, and marine. The fibers are strong, lightweight, and provide excellent mechanical properties to the composite material when combined with resins. The combination of glass fiber textiles and resins creates a composite material that is highly durable, corrosion-resistant, and has a high strength-to-weight ratio. This makes it suitable for various applications where strength, stiffness, and dimensional stability are required. Additionally, glass fiber textiles can be easily molded into complex shapes and provide good insulation properties. Overall, glass fiber textiles are widely used in the reinforcement of resins to enhance the performance and durability of composite materials.

- Q: Can glass fiber textile be used in protective clothing?

- Yes, glass fiber textile can be used in protective clothing. Glass fiber textiles have high strength and heat resistance properties, making them suitable for protective clothing applications where protection against heat, fire, and chemical hazards is required. Additionally, glass fiber textiles offer good insulation and can provide protection against electrical hazards.

- Q: Can glass fiber textile be used in bulletproof vests?

- Glass fiber textile, also known as fiberglass, has various applications in different industries, including aerospace and automotive. It boasts a high strength-to-weight ratio, making it a suitable material for bulletproof vests. When woven into a textile, it offers excellent protection against bullets and other projectiles. Bulletproof vests are designed to prevent bullets from penetrating the wearer's body by absorbing and distributing the bullet's energy. Incorporating glass fiber textile into these vests provides several advantages. Firstly, it is lightweight, allowing for increased mobility and comfort, which is crucial for law enforcement officers and military personnel who require agility in their line of duty. Secondly, glass fiber textile exhibits high tensile strength, enabling it to withstand substantial force without breaking or tearing. This property is essential in bulletproof vests as it minimizes the risk of injury to the wearer. The strong fibers in the glass fiber textile can absorb and disperse the impact energy of a bullet, reducing the likelihood of penetration. Furthermore, glass fiber textile is resistant to heat, moisture, and chemicals, enhancing its suitability for bulletproof vests. It can endure extreme conditions while maintaining its structural integrity, making it a reliable choice for personal protection. However, it is worth noting that glass fiber textile is not the only material used in bulletproof vests. Other materials like Kevlar and Dyneema, renowned for their exceptional ballistic properties, are commonly employed in manufacturing such vests. In conclusion, glass fiber textile is a viable option for bulletproof vests due to its lightweight nature, high tensile strength, and resistance to heat and chemicals. Nonetheless, consulting experts and considering other materials is advisable to ensure the most effective and reliable design for bulletproof vests.

- Q: Can glass fiber textile be used in filtration systems?

- Yes, glass fiber textile can be used in filtration systems. Glass fiber textiles are known for their high strength, durability, and resistance to chemicals, making them suitable for various filtration applications. They have a high filtration efficiency and can effectively capture and remove particles, contaminants, and impurities from liquids and gases. Glass fiber textiles are commonly used in air filters, water filters, oil filters, and other industrial filtration systems. They can be woven or non-woven, and their properties can be customized, such as pore size, thickness, and surface treatment, to meet specific filtration requirements. Overall, glass fiber textiles are a reliable and efficient choice for filtration systems.

Send your message to us

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords