Glass Wool Reinforced Concrete Sheet/Well Fiber Glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

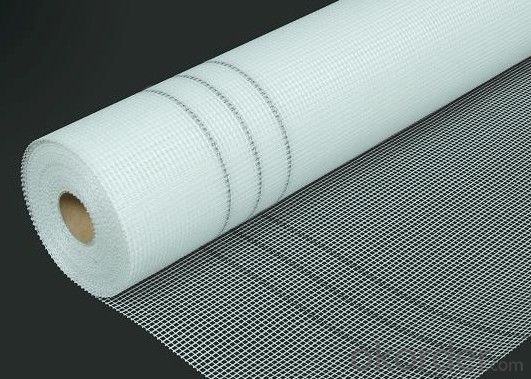

| Place of Origin: | Henan, China (Mainland) | Brand Name: | cnbm | Model Number: | EW7532 |

| Application: | Wall/Roof covering Cloth | Weight: | 250 g/m2 | Width: | 900-1600mm |

| Weave Type: | Plain Woven | Yarn Type: | E-Glass | Alkali Content: | Alkali Free |

| Standing Temperature: | 300°C | Color: | White | Certificate: | ISO9001 |

| Advantage: | waterproof | Length per roll: | 500m | Thickness: | 0.18mm |

| Port: | Any Chinese port | Raw material: | fiberglass yarn |

Packaging & Delivery

| Packaging Details: | Cartons loaded on pallets |

| Delivery Detail: | 30 days after receiving the deposit |

Application

1. All types of thermal insulation and heat protection.

2. Welding blankets and fire curtains.

3. Expansion joints.

4. Basic cloth for coatings and laminations.

Specifications

glass fiber reinforced concrete

Firm mesh and good glue

fiberglass mesh manufacturer

| Fiberglass mesh grid component | 1.glass fiber woven fabric as substrate |

| 2.macromolecular anti emulsion coating | |

| The adventage of fiberglass mesh | |

| 1. good alkali resistance | |

| 2. flexibility and latitude to the high tensile strength | |

| 3. good chemical stability, high strength, light weight | |

| 4. good dimensional stability | |

| 5. strong impact resistance | |

| 6. pest control, fire protection, thermal insulation | |

| 7. other features | |

| Fiberglass mesh usage | |

| 1. wall reinforcing material | |

| 2. reinforced cement products | |

| 3. internal and external wall insulation | |

| 4. granite, marble, mosaic special mesh back paste network | |

| 5. waterproof cloth, asphalt roofing | |

| 6. reinforcing materials of plastics, rubber products | |

| 7. fire board | |

| 8. the grinding wheel base | |

| 9. highway pavement with geogrid | |

| 10. building sealing tape |

Our Services

1. Your inquiry will be replied within 24hours

2. Well-trained and experienced staffs to answer all your inquiries.

3. All our products have 1-year warranties.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.

- Q: What is glass wool board.

- Glass wool is fibrillation by the fusion of the glass, adding binder to solidify the material to make the glass wool roll mat, while the glass wool fibre?diameter is contracted by the centrifugation. The difference is in the centrifugation techniques. the centrifugation techniques currently used most frequent is Saint-Gobain's Isover TEL centrifugation technique, which is the originator of glass wool products. At present the domestic glass wool market is gradually expanding, and enterprise Dacheng Quanhe Chemical Co., Ltd. makes a significant contribution to promote the use of glass wool.

- Q: What are the hazards of glass wool to body?

- Non-energy: glass wool outer cover aluminum foil easily damaged, and glass wool is the opening structure, once broken, water vapor into the wet resistance factor of 0, means that the insulation effect is reduced, a waste of energy, it is equivalent to increase the operation cost.

- Q: What kind of glass wool pipe is this? Where is it sold?

- The glass wool pipe is made of extra-fine glass wool. I do not know this brand. Maybe it is a korean brand.

- Q: What are the applications of centrifugal glass wool board?

- Centrifugal glass wool board is board product with a certain intensity which is made by curing centrifugal glass wool. Whether in high or low temperature environment, it can maintain good heat insulation and sound absorption properties, mainly used for interior wall compartment in advanced architecture, ceiling, heat conservation for iron sheet air duct or aie bellow, sound absorption and noise reduction for studio, machine room and other places.

- Q: Which is the more commonly used thermal insulation material between thermal insulation glass?silk wool and rock wool?

- Glass wool: Glass wool has no shots, having less dust and little irritation to skin and respiratory system as well as light weight, able to be processed to products with long length based on design requirements. It entails less waste, easy to construction. It uses amorphous cellulose which is soft and lathy with no shots, able to serve for more than 20 years. So, in terms of price per ton, rock wool is cheaper than glass wool. But in terms of price per square meter, the prices of glass wool and rock wool are basically flat. If various factors like effect, construciton, service life, safety and bearing structure are took into account comprehensively, glass wool then is more economical. Rock wool: It contains a high content of shots and much dust. It is high irritable to skin and respiratory system, keeping heavy weight, so it cannot be processed for a long time. It entails much waste, difficult to construction. It uses crystalline fiber, which has a high content of shots, is shoyt and unstable. If used for a certain time, its shots and short?fiber will sink, making it unable to maintain a uniform shape, which will seriously affect the insulation effect and needs to be replaced consequently. And the replacement cycle is shorter than 10 years.

- Q: What advantages do thermal insulation glass fiber wool have?

- Thermal insulation glass fiber wool, whose raw materials are glass ball or waste glass, is made by many processes like high temperature melting, wire drawing, winding, weaving, etc. It is an inorganic non-metallic material with excellent performances. There is a wide range of the material. The following are the advantages of it: 1, It has superior heat insulation capability. According to physical principles, excellent heat insulation materials with small heat conduction rate of gas have many air-cavities inside. 2, It is noncombustible without inflammability, deformation and embrittlement, able to resist high temperature up to 700 degrees. It is tested that its combustion performance can reach at A1-level. 3, it does not contain any adhesive, being an non-toxic environmental friendly material without any smell. Compared with traditional glass wool and rock wool products, it does not contain any adhesive, and it will not produce any toxic and acrid smoke at high temperatures. 4, It has high insulativity. Glass fiber is the best insulation material. 5, Glass fiber is insusceptible to strong acid with superior corrosion resistance. It will not lose its functions and characteristics for a long time. 6, It is good in recovery performance. Glass fiber contains numerous fixed air-cativities, which gives it superb restorability. It is insupsceptible to any shock and vibration with a tensile strength of over 1.0kg. 3, It has good insulation, strong heat resistance, great corrosion resistance and high mechanical strength, but it has the disadvantages — brittleness and poor abrasive resistance. Wish it will help you.

- Q: What is the difference among rock wool board, rock wool and glass wool?

- the first one is made by the high temperature injection of mineral, another one is made by the high temperature dissolving injection of glass. They have different color and fiber. their tmeperature resistance is also different.

- Q: What is the difference between Kun Nai glass?wool?board and rock wool?

- Insulation board made of glass wool board is mainly used for tanks, pipes and equipment insulation; basalt or diabase rock wool board for external wall,roofing insulation. It also used for tanks, equipment and building decorative acoustic absorption or acoustic insulation.

- Q: What is the highest temperature that the fireproof glass?cotton can resist?

- It is certain that A level is the highest. A level indicates that it is non-combustible. Level B indicates that it is fire?retardant. Rock wool can resist 800 ℃ and glass wool can resist 450 ℃. The hest perservation effect of matetials of B level is relatively better.

- Q: Why use reflective paper for pipeline package? Such as the caliduct in home is wrapped with a layer of reflective paper outside a layer of glass wool.

- Yes, light reflection can prevent the pipe from absorbing too much heat. Its ok if you don't use reflective material but use material which doesn't absorb heat and has light colors, like sack

Send your message to us

Glass Wool Reinforced Concrete Sheet/Well Fiber Glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords