Mineral Wool for Roofing with Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Blanket For Insulation

INTRODUCTION

In the field of insulation materials, weare mainly specializing in Glass wool products, including blankets, boards andpipes. The advantage of this material is numerous: noncombustible, nontoxic,and resistant to corrosion. It has low weight, low thermal conductivity, stablechemical property, low moisture rate and good hydrophobicity. These productshave been widely used in heat preservation, thermal insulation and soundabsorption in construction, chemical industry, electronic industry, electricpower, metallurgy, energy industry, and communication. High density panelslaminated with facing can be used for Air-conditioning duct system.

The Kinds of Glass Wool Insulation

* glass wool blanket plain or with Aluminum foil -clad(Kraft paper or white PVC/WPSK)

* glass wool board

* glass wool pipe

Our Advantage

* Short delivery time

* Origin of China, FROM A / E/ F

* Stable good quality with competitive price (CE certificate)

TECHNICAL DATA

Item | Unit | Index |

Density | Kg/m3 | 10-100 |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Reshrinking Temp | ℃ | ≥250 |

Thermal Conductibility | w/m.k | 0.038-0.06 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

CE CERTIFICATE

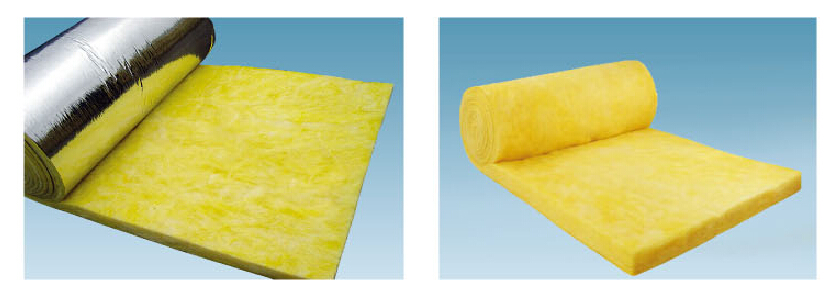

Glasswool Blanket

Introduction

The glass wool blanket is applied for largelaying area. Besides the character of thermal insurance, it also has theperformances of shock absorption and acoustical isolation, especially for middleor low frequency sound. It also can cancel the noise and improve workingenvironment.

The glass wool blanket with aluminum foilsurface has good capability of heat radiation protection.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

This material can be freely cut inconstruction according to the shape required, mainly used in room,noise-canceling system, transportation, refrigerators and household electricappliances for noise canceling.

The blanket with aluminum foil is suitablefor high temperature shops, control room, inner wall of the machine shops, roomseparating and inner liners.

Package

Normal packing: Each roll is wrapped withvacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PESHRINKED BAG can be made with additional charge.

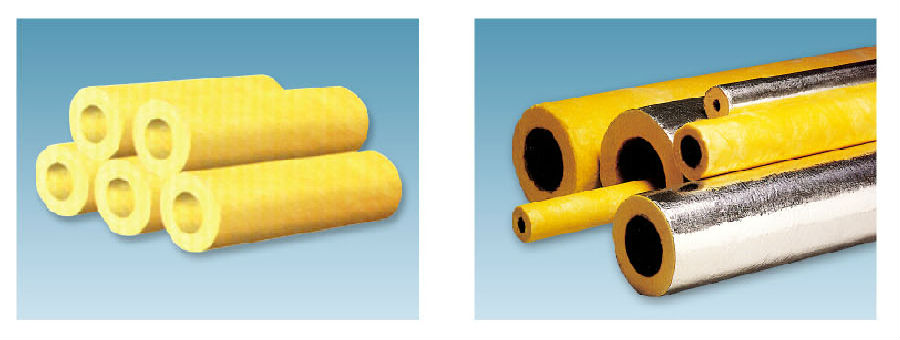

Glasswool Pipes

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is widely used in building, heating powerpipes, air conditioning and refrigerators for thermal insurance, such as hotwater pipes, steam pipes, electric power, petroleum and chemical industries.

Glass wool pipe faced with Alum Foil can beapplied to the surface for preventing moisture and radiation.

Package

Reasonable pieces will be packed withplastic bags or carton box, and then into container.

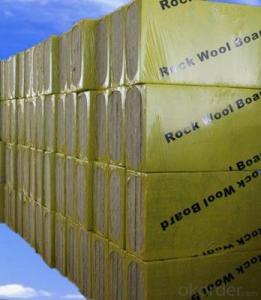

Glasswool Boards

Introduction

Glasswool board is a kind of plate productwith fixed strength after hot-setting of the centrifugal glass wool. It hasexcellent thermal insurance performance in the environment of both high and lowtemperature.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is mainly used for the partition wall inthe high-grade building, such as ceiling, air conduit and inner wall forthermal insurance, machine shops for noise absorption, and metal ceiling forcontrol of moisture.

High density panels with laminated facingcan be used for Air-Conditioning Duct System.

Package

Reasonable pieces will be packed withplastic bags, and then into container.

- Q: What does the thermal insulation test of glass rock wool include?

- Appearance dimensional deviation moisture content areal density density impact resistance combustion performance(oxygen index) average burning time(horizontal method) average burning height (vertical method) board shrinkage principal section thermal resistance radioactivity common testing programs of thermal insulation materials

- Q: How about the quoted price of glass wool board of 96kg?

- Quoted market price. 1, Sheng Ming glass wool board. Weight: 96kg. The texture is glass fiber. Price: 300 RMB yuan. 2, Sheng Ze glass wool board whose texture is glass fiber. Specifications: 1.2mX2mX50mm. Price: 129 RMB yuan. 3, Li Jing glass wool board. Specifications: 2420 * 1220 * 25mm. The texture is glass fiber. Price: More than 159 RMB yuan.

- Q: Can mineral wool, rock wool and glass wool thermal insulation be applied to inverted roofs?

- And wall insulation material can be applied to all kinds of roofing. Glass curtain wall Steel structures are basically solid material hanging while facade walls need adhesive and fixation and other processes.

- Q: What's the necessary performance tests lass wool used for steel structure need to do?

- Flame retardant and thermal insulation performance

- Q: Is the microporous aluminum silicate coated with aluminum wool?

- Aluminum foil with pure embossed aluminum foil and aluminum foil

- Q: Is the glass wool poisonous,

- But long-term inhalation of glass wool is certainly harmful to the body, because the glass wool is made of glass fiber, long-term inhalation of a large number of glass fiber,

- Q: What are the features of glass wool decorative acoustic?panel?absorber suspended ceiling?

- Five features of glass wool decorative acoustic?panel?absorber: 1, Glass wool decorative acoustic?panel?absorber suspended ceiling has excellent sound absorption performance. Installatiion cavity behind the buildings ceiling is usually greater than 200mm. Low frequency sound absorption coefficient will increase greatly as the cavity increases, so the glass fiber ceiling can reach the strong effect of full-range sound absorption. 2, Glass wool decorative acoustic?panel?absorber suspended ceiling surface has no color, so it has a good decorative effect. 3, Glass wool decorative acoustic?panel?absorber suspended ceiling has good fireproof?performance. As the main raw material of the board is incombustible?material, it can reach class A fire?rating. 4, The board of glass wool decorative acoustic?panel?absorber suspended ceiling is light and thin. The board is thin and light and the density is about 2.O ~ 3.Okg / mz, so it is easy to transport and store. 5, Structure of glass wool decorative acoustic?panel?absorber suspended ceiling is simple, so it is easy to install. Glass fiber decorative acoustic ceiling does not have decorative protective surface layer as other glass fiber boards and it will not have fiber scattered which will pollute the environment. So the construction site is clean. It is easy to install with metal keel, both exposed keel or concealed keel. It is also easy to repair and exchange. Besides, it is relatively safe because it add little load to architectural?structure.

- Q: Sound absorption and sound insulation How is the sound insulation effect of glass wool?

- Glass wool, also known as glass fiber, should be the same with foam and some other materials, which have excellent sound insulation and sound absorption effects, and widely used for partition and sound insulation of functional zone in the decoration. Which is a kind of filling material and auxiliary material in the decoration, in addition to considering costs, its practicability should also be considered, and it's also very important to select the right application places. I hope my answer can help you.

- Q: What are the differences between rock wool and glass wool?

- anti-seismic, etc., using boric acid as the main raw material, felt, rock wool felt, fireproof, different raw materials and process 2, mainly used for thermal insualtion of general building or low temperature piping, glass wool is only about 260 degrees Celsius. Its surface can also paste aluminum foil or PVC film, etc., plate of low shot content, low heat conductivity coefficient, specifications . After high temperature melting, obtaining cotton-like fibers of less than 2um, but the maximum service temperature of rockwool is about 600 degrees Celsius, which can be made into boards. Different applications glass wool is generally used for thermal insulation parts of less than 200 degrees Celsius, rock wool is generally used for thermal insulation parts of 450 degrees Celsius , mainly used for thermal insulation of high temperature heat distribution pipeline or electrical equipment, thermal insulation of furnace. Different service life and performance unit weight of glass wool is lower than that of rock wool, and add thermosetting resin adhesive, go through pressurized high temperature setting to create a variety of shapes, iron ore, felt, dolomite, are melted in high temperature. Rock wool board, pipe, gabbro, sound absorption. 1. 3, pipe, pipe products. Rock wool is made by natural rocks such as basalt, which can be used for construction and industrial equipment, glass wool insulation material are based on products like quartz sand, belt. The processed fiber, sodium silicate, tough fiber, bauxite as the main raw material, inorganic fiber, , rock wool pipe and feldspar made of fibrosis

- Q: What's the difference between rock wool board, glass wool board, glass wool felt?

- First question: These three products are used for thermal insulation in roof and wall surface, ship, equipment respectively. Second question: specifications: Rock wool board: 1000 * 630 1000 * 600 1200 * 6001200 * 630 Density is 60-100KG / M3. Imported and exported density is 60-100KG / M3. Glass wool board: 1200 * 600 density: 20-40KG / M3 Glass wool felt : width:1200 density:10-30 [For exoprt] Third question: They can all reach Class A non-combustible. Fourth question: Rock wool board is waterproof and fireproof while glass wool is only fireproof. Fifth question: They can all use tinfoil. Glass wool felt needs to be vacuumized because it has low density. [These are what customers need. ] Sixth question: Add me, and I will inform you the latest changes. Seventh question: It can be used in other ways. Contact me for pecific price.

Send your message to us

Mineral Wool for Roofing with Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords