Fiberglass Mat Tissue - Glass Fiber Chop Strand Mat Rolls, Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1.5

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber Chopped Strand Mat Rolls, Fiberglass Mat

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

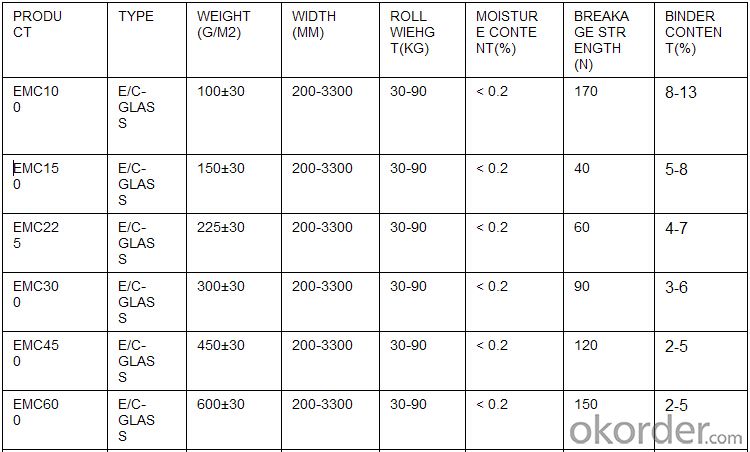

Technical Data:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

- Q: Is fiberglass mat tissue suitable for marine repairs?

- Yes, fiberglass mat tissue is suitable for marine repairs. It is a versatile material that provides excellent strength and durability, making it ideal for fixing and reinforcing various marine structures and components. Fiberglass mat tissue is known for its resistance to water, chemicals, and corrosion, which is essential in a marine environment. It can be used to repair hulls, decks, bulkheads, and other parts of boats and ships, ensuring structural integrity and preventing further damage. Additionally, fiberglass mat tissue is easy to work with and can be applied using various methods, such as wet lay-up or vacuum bagging, making it a popular choice for marine repairs.

- Q: Does fiberglass mat tissue absorb water?

- Yes, fiberglass mat tissue does absorb water. Fiberglass mat tissue is made up of fine glass fibers that are intertwined and bonded together. These fibers have the ability to absorb water, although they do not retain it for long periods of time. When fiberglass mat tissue is exposed to water, the fibers absorb the moisture, causing the tissue to become damp. However, fiberglass itself is not prone to water damage, as the fibers are non-porous and do not deteriorate when wet.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Yes, fiberglass mat tissue is suitable for aerospace interiors. It is a lightweight and durable material that offers excellent fire resistance and insulation properties, making it a suitable choice for various applications in aerospace interiors, such as insulation, soundproofing, and reinforcing materials. Additionally, fiberglass mat tissue can be easily molded and shaped to fit specific design requirements, making it a versatile option for aerospace interior components.

- Q: Does fiberglass mat tissue require any special precautions during handling?

- Yes, fiberglass mat tissue does require special precautions during handling. It is important to wear protective gloves, long sleeves, and a mask to prevent skin and respiratory irritation. Additionally, it is recommended to handle fiberglass mat tissue in a well-ventilated area to minimize the inhalation of dust particles.

- Q: Is fiberglass mat tissue resistant to solvents?

- Yes, fiberglass mat tissue is generally resistant to solvents.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Yes, fiberglass mat tissue can be used for making surfboards. It is a common material used in the construction of surfboards due to its strength, durability, and ability to provide the necessary stiffness and flexibility required for optimal performance in the water.

- Q: Can fiberglass mat tissue be used for roofing applications?

- Yes, fiberglass mat tissue can be used for roofing applications. It is commonly used as a reinforcement material for roofing systems, providing added strength and durability. It helps to prevent cracking and increase the overall lifespan of the roof.

- Q: Can fiberglass mat tissue be used for decorative applications?

- Yes, fiberglass mat tissue can be used for decorative applications. Its versatility and ability to be molded into various shapes make it suitable for creating decorative elements such as wall panels, sculptures, and other artistic installations. Additionally, its lightweight nature, durability, and resistance to corrosion make it an ideal choice for both indoor and outdoor decorative applications.

- Q: Is the Teflon gasket filled with fiberglass or graphite?

- PTFE generally used in static sealing, flange what, dynamic seal with FFKM, chemical resistance and PTFE, but with rubber elasticity

- Q: Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. Fiberglass mat tissue is a versatile material that offers numerous benefits when used in automotive applications. It provides excellent strength and durability, which is essential for automotive parts that need to withstand harsh conditions and heavy usage. Fiberglass mat tissue also has good thermal and electrical insulation properties, making it suitable for applications where temperature resistance and electrical insulation are required. Additionally, fiberglass mat tissue is lightweight, which can help improve fuel efficiency and overall vehicle performance. It is also easy to mold and shape, allowing manufacturers to create complex automotive parts with precision. Furthermore, fiberglass mat tissue is resistant to corrosion, chemicals, and UV radiation, ensuring the longevity and reliability of automotive components. Overall, the unique properties of fiberglass mat tissue make it an ideal choice for various automotive applications, including but not limited to body panels, interior components, structural reinforcements, and sound insulation. Its strength, durability, insulation properties, lightweight nature, and resistance to corrosion and chemicals make it a reliable and cost-effective material for the automotive industry.

Send your message to us

Fiberglass Mat Tissue - Glass Fiber Chop Strand Mat Rolls, Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1.5

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords