Glass Block Jewel

- Loading Port:

- China Main Port

- Payment Terms:

- T/T

- Min Order Qty:

- 5000pcs pc

- Supply Capability:

- 18,000,000Pcs Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Glass Block Jewel:

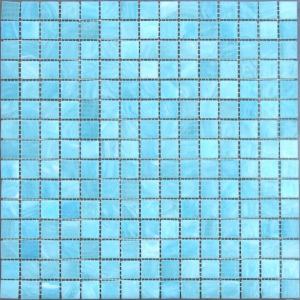

The most common shape of glass tile is square,and the most common length, width and thickness of glass tile are 190mm, 190mm and 80mm or 95mm respectively, and glass tiles with the length, width and thickness of 145mm, 145mm and 80mm or 95mm respectively also sell well. There are many decorative patterns such as cloud-shaped pattern, parallel pattern, slanted strip, lattice, bubble, raindrop, ice crystal, water shadow, mesh-shaped pattern, popular pattern, gemstone grain, diamond grain, etc., and many colors such as pink, green, blue, grey, brown, gemstone blue, gemstone green, etc.

Performance of Glass Block Jewel:

1. Environmental Friendliness

Belonging to sodalime silicate glass system, glass tile, a transparent material, is made by melting silicate inorganic mineral substance materials such as quartz sand, soda ash (Na2CO3) and limestone at high temperature, being a veritable eco-friendly product.

2. Heat-shielding Performance

Due to the diffuse scattering of hollow glass tile and internal negative pressure cavity, a room can get enough light rays and the interior temperature does not rise under strong solar radiation in summer. In winter, the difference between indoor temperature and outdoor temperature can reach 40 DEG C and the air humidity is not influenced because of low thermal coefficient and great loss of blocked heat in the negative pressure cavity. If the glass tile is applied to a building, the room gets cool in summer and is away from torridness, and warms the room, does not cause dryness and saves energy in winter.

3. Sound Insulation Performance

Thanks to sealing negative gas in the hollow glass tile, the tile has high sound insulation property.

4. Light-transmitting and Non-perspective Performance

The light-transmission coefficient of white hollow glass tile is 75%-85%, which is similar to that of the general double-layered hollow glass. There are various decorative patterns on the surface of the glass tile, so the tile is non-perspective, indoor imperceptibility is realized, light rays are scattered around the room, discomfort caused by direct solar radiation is solved and the indoor luminous environment is improved.

5. Fireproof Performance

The fireproof level of hollow glass tile is GB class A. According to Japanese law, it is recognized that single-layer wall has the same performance as the second kind fire door and double-layer wall has one-hour fireproof performance.

6. High Compression Resistance and Shock Resistance

The hollow glass tile has high compression resistance and shock resistance, so that the dead weight of the hollow glass tile can be ignored even in design and construction of very high glass tile wall.

7. Atomization Resistance

The hollow glass tile has outstanding performance in resisting pulverization. For example, the surface of the glass tile does not atomize or form dew when the indoor temperature is 20°C, the humidity is 60% and the outdoor temperature is 2°C below zero, so that the erosion of atomized vapor to the frame is prevented.

Application Range of Glass Block Jewel:

The hollow glass tile has noble, elegant and magnificent decorative effects. It is widely in banks, offices, hospitals, schools, hotels, airports, stations, landscapes, video walls, civil buildings, indoor partitions, stages, sanatoria, gymnasia, playgrounds, apartments, private cruise ships and so on which require beatifying, being a popular novel decorative material in modern international market.

Packing details of Glass Block Jewel:

| SIZE | PACKAGE DETAILS | |

| DIMENSIONS OF BOXES | CAPACITY / 20FCL | |

| 190×190×80 mm | 385×252×200mm / 6 pcs | 9000PCS/1500BOXES |

| 190×190×80 mm | 385×252×200mm / 6 pcs | 9000PCS/1500BOXES |

| 190×190×95 mm | 385×297×200mm / 6 pcs | 7392PCS/1232BOXES |

| 190×190×95 mm | 385×297×200mm / 6 pcs | 7392PCS/1232BOXES |

| 145×145×95 mm | 392×295×155mm / 8 pcs | 12760PCS/1595BOXES |

| 145×145×80 mm | 420×295×155mm / 10 pcs | 14560PCS/1456BOXES |

| 240×240×80 mm | 416×242×246mm / 5 pcs | 5000PCS/1000BOXES |

| 240×115×80 mm | 416×242×246mm / 10 pcs | 10000PCS/1000BOXES |

| 190×90×80 mm | 400×185×200mm /10 pcs | 15000 PCS/1500BOXES |

| 190×190×50 mm | 385×240×200mm /10 pcs | 10000PCS/1000BOXES |

| 145×145×50 mm | 330×295×155mm / 12 pcs | 12504PCS/1042BOXES |

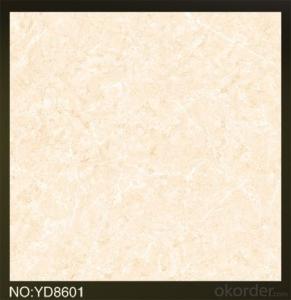

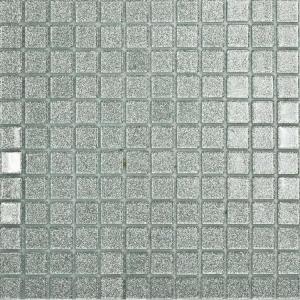

Pictures of Glass Block Jewel:

- Q: I am doing a research project at school on erosion, and one of the members on my research team said something about underground tiles that run water into the nearest body of water. We have been trying to locate a source, or ANY piece of information on this subject, but have failed. Is there anyone who can help us?

- These aren't erosion tiles, they are drainage tiles. Do a web search on tile drainage and you'll find out all you need to know about the subject. BTW, tiles and tile lines are just underground pipes with holes in them, used to lower shallow water tables. It wasn't clear to me that you understood this, so sorry if I'm pointing out the obvious.

- Q: I need help with my white tile grout. Nothing I do keeps/gets it clean. Any tips for an easy fix to dirty grout, or does anyone know if it‘s possible to add color to grout after it‘s been set?

- My Daughter colored my grout lines with crayon I used a acid type grout cleaner got it from the local home center in the tile and grout section. also get a tile grout sealer right after its clean.

- Q: To remoe the old wall tiles between kitchen cabinet takes a lot of time or may damage the sheetrock behind it, can I install granite or new tiles on top of it. Appreciate for any input

- Hi, Well, in order to support wall tiles a special board should be nailed to your wall. It provides much better support than regular dry wall, plus it also has many grooves on it which will help greatly in holding the mortar in place, this type of board goes by many names, I know it by the name hard back, or cement board. If you install tile over tile, you're losing the ability for the mortar to adhere, plus you're adding twice the weight that the hard back was meant to support. What ought to be done, in order to insure your expensive tile job lasts, is to remove the tile, and probably the hard back board behind it. If you're able to just remove the hard back without chipping away at the existing tile, then you get two steps out of the way fairly easily......but the thing is, that hard back is usually nailed very well into place, using many nails, this is to prevent it from flexing, because if it flexes much then the tile would come off the wall. Then once you've gotten the old hard back off of the wall, you'd install a new hard back to put your new tile on. Both Home Depot and Lowes offer tile installation classes for free, plus the people they have in those departments would be able to help you at any time. They'll be able to tell you what all you'll need once you've gotten the old stuff off the wall. Best of luck!

- Q: A family member purchased 12x12 non gloss tiles for our shower stall and I don‘t think I ever saw a shower stall with non gloss tiles. Our old tiles had gloss. Can you use non gloss tiles for the shower stall?

- My husband finished a project with the help of pro tile : For DIY home owners and professional tile installers, Pro Tile Helper shows you everything you need to know to make your next tiling project a success! The creator, a master tile installer with over 20 years experience installing tiles, put all the tips and secrets learned over the years together in one AWESOME APP for your benefit. You will save tons of time installing and save hundreds even thousands of dollars on tools and materials. All this for only $4.99. hope this can help u too =)

- Q: Is there any one who have knowledge about Ceremic tiles? plz suggest me.

- What okorder / We have professional tile fixers, tile distributors, technical advisors and more, to answer whatever questions you might have.

- Q: What are the different types of tile and how much of them does it take to cover 1 square foot nad what‘s the cost of them

- i h8 bodhists.

- Q: I am torn between using roof tile or slate roof? But my husband wanted roof tile more. You think it‘s good to use that?

- Why 2 lengths?. you ought to have the means to get one length for 3m.the less joints the extra constructive.I take it the water is coming from a gutter larger up, in that case in good shape an appropriate bend the place it sheds onto the extension roof and in good shape a downpipe bracket to the wall, this could carry it inflexible at that end, then run your new downpipe for the period of to the place the extension downpipe is,disconnect this from the extension gutter, in good shape a hopper to the precise of the extension downpipe, it feels like a extensive funnel, you will ought to decrease the precise of the downpipe so the prevailing gutter runs into it besides as your new downpipe. fix the recent pipe to the fascia board with yet another bracket, that way you do no longer ought to repair it to the tiles .......good success

- Q: Please don't say wood/tile please say wood/tile is cheaper so I know exactly what you mean, lol. Does it depend on what kind of wood? I assume it does..For just the first floor, 1,040 sq. ft. THANKS!

- Hi, I'm Nick the Tile Man As time goes on tile will be your best bet. I would invest in a good tile so it will last and look good all at once. My web site has info for both tile and wood floor. Just click on the ads for information. Good Luck

- Q: Including the ground and the wall, need to pay attention to what aspects of the problem? Decoration has no experience, hope to say the details, thank you

- 1. Whether the tile is complete, whether the corner burst. 2. Faucet, switch box, floor drain, sewer and other places where there is no crack brick 3. There is no black spot or stain on the surface of the tile 4. Tiles and tiles seams, hand touch can not have a particularly high and low feeling 5. Tapping the tiles to see if there is no empty valley (especially the bathroom wall, the best every one to knock) 6. Level on the tile, see is not vertical, horizontal. 7. There are tiles in the tiles are used to see whether the missing parts 8. Whether the same tile is straight, tile size.

- Q: The bathroom tile in my recently purchased house isn‘t finished. The previous owner used floor tile to surround the tub; he/she left many pieces of tile unfinished, but luckily left us a stack of the tiles so we could finish it off. However, we don‘t have an unlimited supply of these tiles, so we‘d like to get it right with as few tries as possible!I‘m wondering: -I need to fit the tub faucet and knobs within two 12 square tiles. What‘s the best way to measure the placement of the fixtures? Is it possible to make some sort of template that I could transfer to the tiles? -Can I make the cuts for the fixtures using a hacksaw-type tile saw blade, or should I buy a tile drill bit? (I realize it rather depends on where the fixtures fall within the tile-- but if I don‘t need to buy both, I won‘t waste my money. )Thanks!

- If you are trying to use floor tile on the walls, I would go to a tile store and have them make the cuts you need (use a grease pencil to mark the tiles) the two methods described in the first two answers can help you. but if you have ever tried to cut floor tile with one of those hacksaw tile blades you would know that it is VERY DIFFICULT, wall tile cuts no problem but floor tile is much tougher. also if you know where they were purchased they may cut them for you for free.

1. Manufacturer Overview

| Location | Shandong, China (Mainland) |

| Year Established | 2000 |

| Annual Output Value | 235.438 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2009 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao PORT, China |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 112 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Glass Block Jewel

- Loading Port:

- China Main Port

- Payment Terms:

- T/T

- Min Order Qty:

- 5000pcs pc

- Supply Capability:

- 18,000,000Pcs Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords