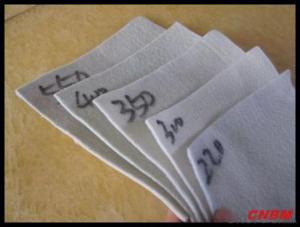

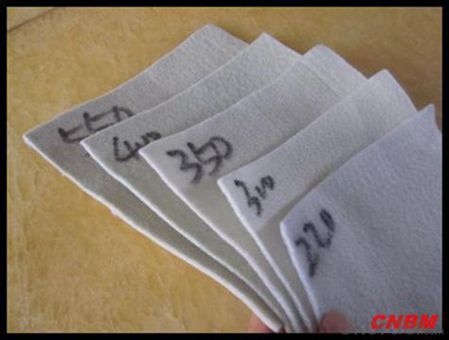

Geotextile Filter Layer Needle Punch Geotextile for Railway from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

1.Unit weight 100g/sqm,150g/sqm,200g/sqm,250g/sqm,300g/sqm,350g/sqm,400g/sqm,450g/sqm,500g/sqm,600g/sqm,800g/sqm

2.Width

1m-8m

3.Length:

Per clients' request

Application of geotextile

Filtration

It can be the filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Protection

It prevents the bank from being washed out, protects the bank and the

bottom, prevents the water and soil from being washed away.

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Design of interlocking turf slope protection brick directly on the geotextile, river earth side by 1: 2.5 slope excavation, began laying geotextile, grass sand and gravel, can lay it? Geotextile laying on the grassroots what are the requirements? More

- No special requirements, mainly from the role of filtering, over the water, but I, specializing in the production of geotextile, geomembrane, wish smooth

- Q: Can geotextiles be used in green space development projects?

- Yes, geotextiles can be used in green space development projects. Geotextiles are versatile materials that can be used as a barrier or separator to prevent soil erosion, support vegetation growth, and improve drainage in green space areas. They can be utilized in various applications such as stabilizing slopes, reinforcing embankments, and promoting the establishment of healthy vegetation.

- Q: 300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q: How do geotextiles prevent soil erosion?

- Geotextiles prevent soil erosion by acting as a barrier that stabilizes the soil, allowing water to pass through while preventing the movement of soil particles. They provide reinforcement to the soil, reducing the erosive forces of wind and water, and promoting vegetation growth by retaining moisture and nutrients in the soil.

- Q: What are the different geotextile installation equipment and tools?

- Some different geotextile installation equipment and tools include: 1. Excavators: Used to prepare the ground by digging trenches or removing existing soil. 2. Trenchers: Specifically designed to create narrow trenches for laying geotextile materials. 3. Rollers: Used to compact the soil and ensure proper adhesion of the geotextile fabric. 4. Spreaders: Designed to evenly distribute the geotextile material over the prepared surface. 5. Staple guns: Used to secure the geotextile fabric to the ground or other surfaces. 6. Tensioners: Used to stretch and tighten the geotextile fabric during installation. 7. Cutting tools: Such as utility knives or scissors, employed to trim the geotextile material to the required size. 8. Anchor pins: Used to secure the geotextile fabric in place and prevent shifting. These tools and equipment aid in efficient and effective installation of geotextile materials, ensuring their proper functionality and longevity.

- Q: How do geotextiles help in preventing differential settlement?

- Geotextiles help in preventing differential settlement by providing a stable base for the soil beneath structures. They distribute the load more evenly, reducing any differential movement that can cause settlement.

- Q: How do geotextiles affect soil consolidation?

- Geotextiles can positively affect soil consolidation by improving the overall stability and load-bearing capacity of the soil. They can act as a separator, preventing the intermixing of different soil layers, which aids in achieving proper consolidation. Additionally, geotextiles can enhance drainage and prevent water buildup, reducing the risk of soil erosion and improving consolidation.

- Q: What are the factors to consider when selecting geotextiles for mining applications?

- When selecting geotextiles for mining applications, several factors need to be taken into consideration. These factors include the type and characteristics of the soil or rock, the load and stress exerted on the geotextile, the required strength and durability of the geotextile, the desired filtration and drainage properties, the potential for chemical exposure or environmental degradation, and the cost-effectiveness of the geotextile solution. Additionally, the availability and accessibility of the geotextile, as well as any regulatory requirements or industry standards, should also be considered in the selection process.

- Q: What are the considerations for geotextile selection in landfill projects?

- The considerations for geotextile selection in landfill projects include factors such as the required strength and durability of the geotextile, its ability to resist punctures and tearing, its compatibility with the waste material, and its resistance to chemical degradation. Other factors to consider include the geotextile's permeability, its ability to retain soil particles while allowing for proper drainage, and its cost-effectiveness. Additionally, the geotextile should be selected based on its compliance with regulatory requirements and standards for landfill construction.

- Q: Can geotextiles be used in geotextile wrapped columns?

- Yes, geotextiles can be used in geotextile wrapped columns. Geotextiles are commonly used in geotechnical engineering to enhance soil properties, provide drainage, and prevent erosion. When used in geotextile wrapped columns, they can provide additional reinforcement, improve stability, and control soil movement.

Send your message to us

Geotextile Filter Layer Needle Punch Geotextile for Railway from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords