Geotextil Tecido - Non-Woven Geotextile Fabric 100% PP Spunbond with High Stabilization and Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

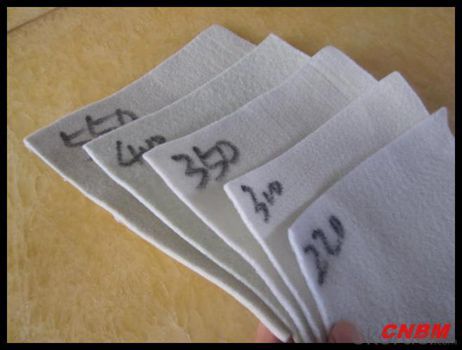

Specification

Description

CMAX's complete line of High Performance geotextiles are uniquely designed to produce a

superior geotextile fabric which yields exceptional strength combined with increased water

flow and filtration properties.

Geotextile-Railways

saimanIn Railway tracks the use of high strength woven geotextiles increases the periods

between track maintenance. They are placed between the existing formation and the ballast

layer to prevent the sub-grade from pumping in to the ballast layer, thereby maintaining

structural integrity.

Geotextile-Erosion Control

saimanGeotextiles prevent the erosion of soil on the slopes and hilly areas. Nonwoven

Geotextile will give effective drainage for water flow and on other side it will prevent

the soil particle from washing out.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in stormwater detention systems?

- Yes, geotextiles can be used in stormwater detention systems. Geotextiles are commonly used to separate different soil layers and provide filtration and drainage in stormwater management systems. They can help prevent soil erosion, improve water quality, and enhance the overall performance of stormwater detention systems.

- Q: Artificial lake geotextile practices

- Library and slope with a composite geomembrane all laying, I specialize in the production and construction of geotextile materials

- Q: Can geotextiles be used in mining operations?

- Yes, geotextiles can be used in mining operations. Geotextiles are commonly used in mining to reinforce soil and prevent erosion, control sedimentation, and provide stability to slopes and embankments. They are also used for filtration, drainage, and separation purposes in mining applications.

- Q: Can geotextiles be used in geocomposite drains?

- Yes, geotextiles can be used in geocomposite drains. Geocomposite drains typically consist of a geotextile fabric wrapped around a core material, such as a perforated pipe. The geotextile helps to filter and separate fine particles from the core material, preventing clogging and enhancing drainage efficiency.

- Q: What is the application of geotextile?

- Geotextile is mainly used for various geotechnical projects, such as water conservancy, transportation, construction, harbor, airport and military facilities, to enhance, drainage, filtration, protection and other effects, can improve the quality and service life.

- Q: Can the tunnel longitudinal drains be wrapped with geotextiles and wrapped with a waterproof board?

- With geotextile wrapped drainage pipe is generally played the role of seepage drainage, do not need waterproof board (you said the waterproof board should be geomembrane it) Chong Hong geotextile material manufacturers

- Q: What are the cost implications of using geotextiles?

- The cost implications of using geotextiles can vary depending on several factors. Initially, geotextiles may have a higher upfront cost compared to traditional materials. However, they can provide long-term cost savings by extending the lifespan of infrastructure and reducing maintenance requirements. Geotextiles can also minimize the need for expensive excavation and replacement of poor soil, resulting in overall cost reductions. Additionally, the use of geotextiles can enhance construction efficiency, reducing labor costs and project timelines. Therefore, while there may be initial investment, the long-term cost implications of using geotextiles can be beneficial.

- Q: What are the advantages of using geotextiles in green roof design?

- There are several advantages of using geotextiles in green roof design. Firstly, geotextiles help to retain water in the soil, preventing excessive runoff and reducing the strain on drainage systems. Secondly, they provide a protective layer that prevents roots from damaging the waterproofing membrane of the roof. Additionally, geotextiles can improve the stability and structural integrity of the green roof by preventing soil erosion and promoting even distribution of water and nutrients. Lastly, geotextiles can aid in weed control, reducing the need for herbicides and maintenance. Overall, incorporating geotextiles in green roof design enhances the functionality, longevity, and sustainability of the green roof system.

- Q: How do geotextiles help with siltation control in construction sites?

- Geotextiles help with siltation control in construction sites by acting as a barrier that prevents the movement of soil particles while still allowing water to pass through. They are typically placed on the ground surface or used as erosion control blankets, effectively reducing erosion and sediment runoff. This helps to minimize the amount of silt and sediment that enters nearby water bodies, maintaining water quality and protecting the surrounding environment.

- Q: How do geotextiles contribute to green building certifications?

- Geotextiles contribute to green building certifications by providing sustainable and eco-friendly solutions for various construction applications. They can help improve stormwater management, erosion control, and soil stabilization, reducing the environmental impact of construction projects. By incorporating geotextiles in building designs, projects can meet the requirements of green building certifications that prioritize sustainable practices and materials.

Send your message to us

Geotextil Tecido - Non-Woven Geotextile Fabric 100% PP Spunbond with High Stabilization and Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords