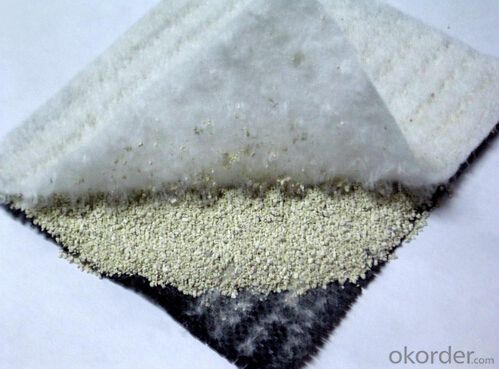

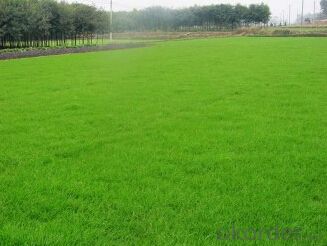

Geogrids and Geomembranes Nutrition Geotextile for Planting Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Features:

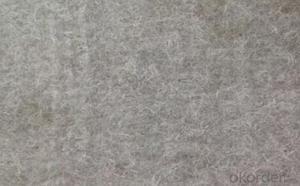

Polyester filament geotextile is made by polyester textile needle consolidation , product specifications from 80-800g/m2 , it is geosynthetic application in geotechnical and civil engineering , they are arranged in three-dimensional structure of the fiber . In addition to having good mechanical properties, but also has a good aspect to the drainage performance and good elongation properties and high resistance to biological , acid , anti-aging chemical stability . Meanwhile , it also has a wide range of pore size , pore distribution tortuous , excellent permeability and filtration performance .

2. Action:

1, Water conservancy project dams and slope of filtration , channel isolation, impervious ;

2, Highways , railways, airport runways based isolation, filtration , drainage, slopes, retaining walls and pavement reinforcement, drainage ;

3, Port engineering soft ground , beach causeway , harbor piers and breakwaters reinforcement, drainage ;

4, Polyester filament geotextile has been widely used in the field of infrastructure construction , and gradually be applied to a wider range of fields.

3. Technical data:

Index | Remark | |||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

Deviation of mass per unit area % | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | |

Thickness mm ≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 | |

Width deviation % | -0.5 | |||||||||||

Break strength kN/m | 4.5 | 7.5 | 10.5 | 12.5 | 15 | 17.5 | 20.5 | 22.5 | 25 | 30 | 40 | Vertical and horizontal |

Break elongation % | 40~80 | |||||||||||

CBR bursting strength kN ≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 | |

Equivalent aperture mm | 0.07~0.2 | |||||||||||

Vertical permeability cm/s | K*(10-4~10-3) | K=1.0~9.9 | ||||||||||

Tear strength kN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 | Vertical and horizontal |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does we support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: How much is the geogrid return

- Generally speaking, the 10-15cm should be judged according to the specification

- Q: Fiberglass geogrid is mainly used for old road reconstruction, the main purpose is to reduce reflection

- (1) due to the existence of joints and cracks, the old cement concrete pavement as the base of the overall strength is reduced, and under the action of external forces, the asphalt overlay in the three-dimensional stress state. The vehicle passing adiscontinuous board, because the joints and cracks on both sides of the adjacent plate reflecting cracks of vertical displacement difference, asphalt overlay in the corresponding position of the larger shear stress, the shear stress is the main reason of asphalt pavement reflection cracks produced. Usually referred to as the load type reflective crack.(2) due to the exposure of the pavement in the atmosphere, the asphalt overlay and the old cement concrete face have the shrinkage and the temperature stress. Because of the Old Cement Concrete Pavement Stress in the joints is not continuous, so the asphalt overlay and bear it and the old pavement caused by temperature stress, especially under low temperature in winter, the asphalt overlay at the seams, cracks, because of excessive tensile stress and cracking formation temperature reflection crack.

- Q: What are the factors that affect the performance of geogrids under cyclic loading?

- There are several factors that can affect the performance of geogrids under cyclic loading. These include the type and quality of the geogrid material, the design and installation of the geogrid, the magnitude and frequency of the cyclic loading, the properties of the surrounding soil, and the environmental conditions. Additionally, factors such as aging, degradation, and maintenance of the geogrid can also impact its performance under cyclic loading.

- Q: What are the general laying methods of Geogrid

- Mechanism of glass fiber grid to prevent reflection crackThe above four methods are used to calculate the thickness of asphalt overlay on old cement concrete pavement. In order to prevent the occurrence of reflective cracks, the use of thick asphalt overlay. But relying solely on the increase of the overlay thickness has its drawbacks: on the one hand to increase the overlay thickness by the pavement elevation limit (Ningtong highway overpass bridge clearance in the overlay should meet the requirements of 4.8m); another is a substantial increase in the thickness of overlay will increase the cost of pavement, and under the condition of high temperature in summer the asphalt mixture high-temperature creep prone to rutting, will lose the advantage of strong foundation and thin surface due to the old cement concrete plate base generated, thus thickening asphalt overlay, this approach is not desirable.

- Q: Are geogrids resistant to alkali degradation?

- Yes, geogrids are typically resistant to alkali degradation.

- Q: Are geogrids resistant to acid degradation?

- Yes, geogrids are typically resistant to acid degradation.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are commonly used in conjunction with geosynthetic clay liners to enhance their tensile strength and prevent their displacement. This reinforcement helps to improve the overall stability and performance of waste containment facilities.

- Q: What is the typical geogrid roll weight for specific applications?

- The typical geogrid roll weight for specific applications can vary depending on factors such as the type of geogrid, the intended use, and the desired strength requirements. However, geogrid rolls commonly range from 50 to 150 pounds for standard applications.

- Q: What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one direction, making them suitable for applications requiring reinforcement in a single direction. Biaxial geogrids, on the other hand, have strength and stiffness in two perpendicular directions, allowing for reinforcement in multiple directions. This makes biaxial geogrids more versatile and applicable to a wider range of projects.

- Q: What are the advantages of using geogrids in ground improvement for load transfer platforms?

- Geogrids offer several advantages in ground improvement for load transfer platforms. Firstly, they provide enhanced stability by distributing load forces across a wider area, reducing the risk of settlement or failure. Secondly, geogrids increase the bearing capacity of the soil, allowing for the construction of heavier structures or equipment. Additionally, these grids improve soil confinement, preventing the lateral movement of soil particles and reducing the potential for erosion. Moreover, geogrids are easy to install and can be cost-effective compared to alternative methods, making them a preferred choice for ground improvement projects.

Send your message to us

Geogrids and Geomembranes Nutrition Geotextile for Planting Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords