General Purpose Pumping LYB vertical arc gear pump oil pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Vertical Installed Pump for Ship

Characteristic: It has characteristics low noise, long life and high efficiency.

Shaft seal: This series of pump adopt mechanical sealing. It also adopts the packing seal according to the requirement of customer.

Temperature: The max environment temperature is 50 °C and the max use temperature is 80 °C.

( If you are looking for arc gear pump used in ships, just need it -- LYB Vertical Arc Gear Pump. )

| Name | Value |

| Brand | China |

| Type | LYB arc gear pump |

| Model | LYB VERTICAL ARC GEAR PUMP |

| Temperature | Environmental temperature: <50°c Use temperature: <80°c |

| Viscosity | 5~1500cSt |

| Rated pressure | 0.6Mpa |

| Frequency | 50Hz 60Hz |

| Certification | GL, ABS, BV, CE, CNV etc. |

| Deliever time | About 25~40 days according to quantity. |

More Details:

| MOQ | 1 SET |

| Certification | GL, ABS,BV, CE, 3C, ISO9001-2000, GJB9001A-2001 |

| Package | Standard export carton or plywood case. (By sea or by air) |

| Deliver date | Within 25 working days after confirm orther |

| Warranty | 1 year |

| Customized | Available |

LYB arc gear pump

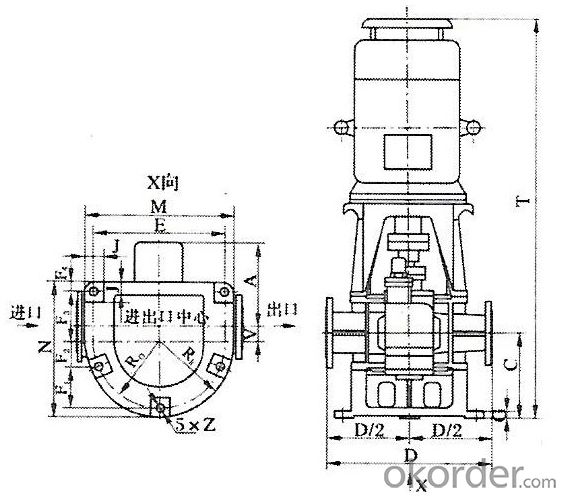

Outline and Installation diagram

Performance parameter

Rated pressure: 0.6Mpa

| Model | Diameter | Rated Capacity(m3/h) | |||

| Inlet*Outlet | 60Hz | 50Hz | |||

| 1180rpm | 900rpm | 970rpm | 720rpm | ||

| LYB20 | Φ100*Φ80 | 24 | - | 20 | - |

| LYB25 | 30 | - | 25 | - | |

| LYB30 | Φ125*Φ100 | 36 | - | 30 | - |

| LYB40 | Φ150*Φ125 | 48 | - | 40 | - |

| LYB50 | Φ150*Φ125 | 61 | - | 50 | - |

| LYB65 | - | 65 | - | 55 | |

| LYB80 | - | 80 | - | 65 | |

| LYB90 | - | 90 | - | 75 | |

| LYB100 | Φ200*Φ150 | - | 100 | - | 85 |

| LYB150 | - | 150 | - | 125 | |

| LYB175 | Φ250*Φ200 | - | 175 | - | 145 |

| LYB200 | - | 200 | - | 165 | |

All Products can be matched with different motors as customer's requirment

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

- Q: What is a water pump coupling device?

- The automatic coupling device of the water pump coupling device has compact structure and small occupation area. The sump pump works because it is submergedThe utility model can be directly installed in a sewage pool, and no special pump house is needed to install a pump and a machine, thereby saving large amounts of land and infrastructure expenses

- Q: What are the internal losses in centrifugal pumps? How did they come about?

- Volume loss: loss due to leakage;3. mechanical loss

- Q: What is the dry running protector of screw pump? What's the principle and function? Thank you

- Principles are generally temperature sensing, such as: when the screw pump by air, the stator and rotor will be heated due to friction,

- Q: Pump unloading in hydraulic transmission,

- Can be used for short-term shutdown, pump non-stopNo unloading, usually through the overflow valve back to the tank, high pressure, power, at this time insurable pressure, and so on

- Q: Why can't the inlet of centrifugal pump be negative pressure?

- However, the centrifugal pump will have its import pressure requirements, which is to prevent cavitation, that is, the fear of the delivery of liquid at low pressure will occur gasification. Centrifugal pump has an important parameter called NPSH, for example relating to the inlet pressure, the pump NPSH, 4 meters, it means that the absolute pressure of imports should be higher than the saturated steam conveying fluid pressure of liquid column is 4 meters high, so, when it is at a temperature of saturated vapor pressure for water transport 2 meters, 4+2=6 meters minimum inlet absolute pressure. Because the absolute pressure is 10 meters water column atmospheric pressure, at this time the entrance negative pressure is 10-6 meters =4 meters water column.

- Q: The main factors affecting the performance of centrifugal pumps

- The low specific speed pump, on the other hand, is suitable for smaller flow and higher lift. When the pump outlet pipe diameter at the same time, if the two pumps flow similar, smaller than the speed of small head, shaft power consumption is also large. Generally speaking, the centrifugal pump with smaller revolutions than the impeller has a narrow outlet width and a large outer diameter, and the channel formed by the blade is narrow and long. If the ratio of revolutions is large, the impeller outlet is wide and the outer diameter is small, then the flow passage is short and wide.I hope my answer will be helpful to you. I hope to adopt it!

- Q: How many kilograms of water pump are there in the automatic washing machine on the market?

- Longer service life. Automatic switch water pump, car wash automatically open and stop, easy to operate, not easy to bad, repair rate is low!!!

- Q: Is vane pump good or gear pump good?

- The main working parts of vane pump is provided with a plurality of sliding vane rotor, when the rotor rotates, the eccentric configuration of stator cavity contour or rotor, blade sliding slot in leaves due to volume changes, resulting in the suction effect. The similarities are: 1, rotary type positive displacement pump has self-priming ability, but are not allowed to do; 2, with continuous flow pulsation, but also have flow and pressure; 3, the theory of flow is determined by the working parts of the size and speed, has nothing to do with discharge pressure; 4, rated discharge size, pressure and working parts mainly depends on the pump speed is independent of the sealing parts and bearing capacity; differences: 1) gear pump structure is more simple, reliable, low price; vane pump has complicated structure and high manufacturing precision parts, the blade is easy to get stuck, more sensitive to the oil clean degree and viscosity.

- Q: Why can't the centrifugal pump pump the vacuum?

- Running process: depending on the centrifugal pressure of the liquid in the impeller, the liquid is sucked into the liquid, and the liquid in the pump shell has the conversion of the energy form, so that the fluid can obtain the mechanical energy mainly with the static pressure.The characteristics of the system: the suction diameter than out of large diameter, the general valve installed.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- When the filter is in normal operation, the impurity will be trapped in the upstream of the filter (filter medium). As the accumulation of impurities, the filter media will be blocked, and the direct performance is that the circulation will decrease. Usually, when the flow drops to a set point (the industry is usually judged by the pressure drop),

Send your message to us

General Purpose Pumping LYB vertical arc gear pump oil pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords