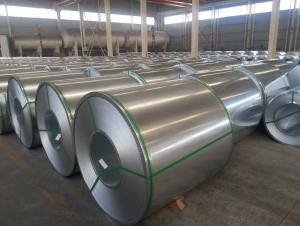

Gavalume steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

a.) Construction: roof, walls, garage, soundproof walls, pipes and combined house, etc.

b.) Car: muffler, exhaust pipe, wiper accessories, fuel tanks, truck boxes, etc.

c.) Appliance: refrigerator backplane, gas stove, air conditioner, microwave, LCD border CRT explosion-proof belt, LED backlight, electrical cabinets, etc.

d.) Farm: pigsty, henhouse, granary, greenhouse with pipes etc.

e.) Other: broken thermal insulation cover, heat exchanger, dryer, warm water device, etc.

Coating ingredients respectively according to the weight ratio from 55% of the aluminum and 43.4% of zinc, 1.6% of silicon composition.

Standard | GB/T14978, ASTM A792M, JIS G3321, EN10215, etc |

Grade | DX51D-AZ, DX53D-AZ, SGLCC, SS255-550, etc |

Thickness | 0.35-2.3mm |

Width | 600-1270mm |

Inner Diameter | 508mm |

AZ Coated | AZ 50-200 |

Coil Weight | 12Tons max |

Technology | hot dip aluminum and zinc |

Post-processing | Chromated, Anti-finger printed, Oiled, etc |

- Q: Consider a steel rod of diameter 4.5 mm and length 3.3 m. If a compressive force of 4900 N is applied to each end, what is the change in the length of the rod?

- You need to calculate the stress on the rod and compare this with the mechanical properties of the steel. It would help if you were given more info. You will need to know something about the steel such as the yeild stress and E, the modulus of elasticity. The value of E is about the same for a wide range of steels. So long as the applied stress is below the yield stress, the strain is all elastic and is calculated from E. The real answer is that you can not answer this question since you do not know what the temperature is. Given the applied load, the change in length will be much different at room temperature than at 1500C.

- Q: What are the different surface finishes for steel coils?

- Some common surface finishes for steel coils include hot rolled, cold rolled, galvanized, and coated finishes. Hot rolled coils have a rougher surface and are typically used for structural applications. Cold rolled coils have a smoother surface and are often used in applications requiring a high-quality finish. Galvanized coils are coated with a layer of zinc to protect against corrosion. Coated finishes include options like painted, epoxy, or vinyl coatings, which provide additional protection and aesthetic appeal.

- Q: How are steel coils inspected for oil or rust residues?

- Steel coils are typically inspected for oil or rust residues through visual examination, as well as using various testing methods such as wiping the surface with a white cloth to check for any visible stains or residues. Additionally, some inspectors may also use specialized equipment such as ultraviolet lights or moisture detectors to identify any hidden oil or rust contaminants.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials.

- Q: What are the different surface treatments applied to steel coils?

- Some of the different surface treatments applied to steel coils include galvanizing, which involves coating the steel with a layer of zinc to protect it from corrosion, painting or powder coating to enhance the aesthetics and provide additional protection, and passivation to remove any impurities on the surface and improve its corrosion resistance.

- Q: Can steel coils be coated with zinc-aluminum alloy?

- Yes, steel coils can be coated with zinc-aluminum alloy, which is often referred to as galvalume or zincalume coating. This type of coating provides excellent corrosion resistance and durability to the steel coils, making them suitable for various applications in industries like construction, automotive, and appliances.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are widely regarded as superior to other types of metal coils due to their exceptional strength and durability. Steel is known for its high tensile strength, which means it can withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require a high level of structural integrity, such as in the construction and automotive industries. In addition to their strength, steel coils also offer excellent corrosion resistance. Steel can be coated with various protective layers, such as zinc or paint, to prevent rusting and ensure longevity. This makes steel coils suitable for outdoor and marine environments where exposure to moisture and harsh weather conditions is common. Furthermore, steel coils have a wide range of mechanical properties, which can be tailored through different manufacturing processes. This allows for the production of steel coils with specific characteristics, such as high ductility, heat resistance, or electrical conductivity, to meet the requirements of various industries. Compared to other metal coils, such as aluminum or copper, steel coils often have a lower cost. Steel is one of the most economical metals available, and its abundance in nature contributes to its affordability. This makes steel coils a cost-effective choice for many applications, especially when large quantities are required. Overall, steel coils stand out due to their exceptional strength, durability, corrosion resistance, versatility, and affordability. These characteristics make steel coils a preferred choice for a wide range of industries, from construction and manufacturing to transportation and energy.

- Q: I want to buy a machete made of 1055 carbon steel, and want to know if this steel is durable for repeated use, or even combat use.

- This Site Might Help You. RE: What is the level of dependability of 1055 carbon steel? I want to buy a machete made of 1055 carbon steel, and want to know if this steel is durable for repeated use, or even combat use.

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped. Steel coils are flexible and can be easily manipulated into various forms or shapes through processes like bending, rolling, or stamping.

- Q: i have a pocket knife that is stainless steel that my mom found in the parking lot and i am wondering if oxygen peroxide will rust it? and if it dose is there something else i can use to get rid of the rust?

- Stainless does rust over time (EVERYTHING rusts it's called oxidation) Whenever something comes in contact with oxygen, the molecules will bond with the oxygen to form an oxide. Iron form iron oxide or rust which is reddish brown, apples turn brown after several minutes after it's been bitten. It all depends on the type of material used to manufacture the stainless. Stainless is made up of .2%-2% carbon, 11%%-28.5% chromium and iron. Some stainless is further advanced by adding other metals like nickel, molybdenum or niobium. Most stainless pocket knives are either normal steel coated with stainless or a cheaper form of stainless (it will have a high 300 number or very low 400 stamped on it). Other time, stainless will rust when a form of iron scratches the surface and contaminates the stainless, this is easily treatable if you get it quickly. Oxygen peroxide should not rust it, since the oxygen has already bonded with each other to form peroxide (2 oxygen molecules). It's the simplest form, but not the most stable (which means it could make your knife rust further). But I recommend steel wool or a scratch pad used to clean cook where (usually green or brown) to remove the rust.

Send your message to us

Gavalume steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords