Gate Valve Non-rising Stem of Best Price and Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

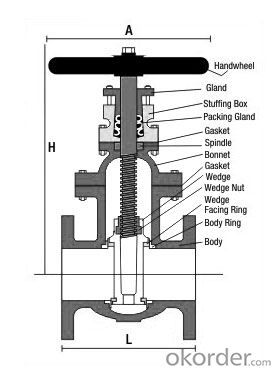

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

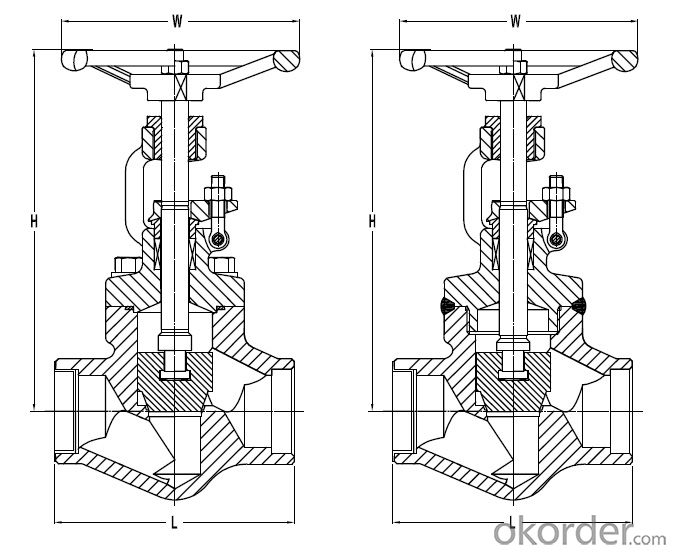

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What are the working principles of the electric gate valve?

- You see what type of electric valve, is integral or ordinary type, if the overall type Denso took power on the line, is generally 380V and 220V power supply, and then according to their own needs and then open the signal line, in place and closing in place and remote control line, valve position feedback signal 4~20ma over torque protection, fault signal. Ordinary type electric valve should be equipped with the control box, the motor is the true story and the inversion, and in general to a trip signal signal is normally open and normally closed, closed in place are normally open and normally closed two points according to their own needs wiring, three lines and then open and close control of the line of control there are also 4 lines to control some manufacturers, as well as the valve position, some three lines connected with the potentiometer, some installed valve position transmitter is connected with two lines, and over torque protection fault signal.

- Q: What is the difference between the cut-off valve and gate valve, the general will use the cut-off valve instead of gate valve

- Yes. Globe valves and gate valves are indeed common in certain piping and operating conditions.

- Q: Why is gate valve or butterfly valve used for water pump?

- General pressure is small, use the butterfly valve, when the pressure is big, use the gate valve. The two main function of the valve is to adjust the flow and easy to overhaul.Zibo Boshan new Duke water supply equipment

- Q: Gate valve DN65 what does that mean?

- DN65 indicates that the valve bore is 65CM.The gate (gate valve) is a headstock ram, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed doors, discomfort pumpsparameters vary, usually 5 degrees is not high, medium temperature is 2 degrees 52'. To improve its manufacturability, make up for the deviation of the angle of the sealing surface during processing. This gate is called an elastic ram.

- Q: What is the meaning of socket welding gate valve A105, D&S:STLT, STEM:13Cr, CL800, SW, AP1602, BB-BG-OS&Y?

- Body material: A105Sealing surface material: STLStem material: 13CrPressure rating: CL800Connection: SWImplementation criteria: AP1602BB-BG-OS&Y: plain rod support, bolt connection, flange valve cap.

- Q: Why does the fire hydrant box in the air defense area need to be added with gate valves?

- Code for design of basement for civil air defence GB50038The installation and installation of the protective valve on the water supply line of the 6.2.13 air defense basement shall comply with the following requirements:OneWhen the water supply pipe from the entrance into, should be set up in the inner protective sealing door;

- Q: What is the difference between Z41X gate valve and Z45X gate valve?

- 2 kinds of valve function, there is no difference.Nothing more than a one with a bright bar. One is a dark pole.Dark pole is cheaper.Everything else is the same. Contact me if you need another valve. Zhejiang Futai Valve Co., ltd.. The contact picture is in the head.

- Q: Function of gate valve

- Valve strengths: (1) fluid resistance is small, due to the valve inside the valve channel is straight, and the medium flow through the valve does not change its direction of movement, so the fluid resistance is small. (2) the opening and closing moment is small, opening and closing more effort, as the gate valve opening and closing, the direction of movement of the gate and the direction of the media movement vertical, compared with the cut-off valve, valve opening and closing more effort. (3) the direction of the movement of the media is not limited, no disturbance, no pressure reduction, the media can flow in any direction from both sides of the gate valve, and all can achieve the purpose of use, more suitable for the direction of the movement of the medium may change in the pipeline. (4) the length of the structure is relatively short, because the gate of the gate valve is vertical inside the valve body, and the stop valve clack is horizontally placed in the valve body, so the length of the valve is shorter than the cut-off valve. (5) the sealing function is good, when the full opening, the sealing surface is less eroded. (6) when fully open, the sealing surface is less eroded by the working medium than the cut-off valve. (7) the shape is relatively simple, the forging technology is good, and the scope of application is wide.

- Q: Notes on flat gate valves

- internal structureThe 1 seat O ring seal and preload floating seat structure, so that import and export of two-way valve seal plate; and the structure of the normal valve opening and closing torque only 1/2, can easily open and close valves2. when fully open, the channel is smooth and straight, the flow resistance coefficient is extremely small, and there is no pressure loss. The pipeline can be cleaned through the hair bulb3 the packing structure with the ability of self sealing, without frequent adjustment, opening and closing very lightweight, and reliable seal, the stuffing box is arranged at the auxiliary seal oil into the structure, absolutely reliable sealing performance, thereby achieving zero leakage; solve the shortcomings of the general valve packing leakage of the most vulnerable4., when the flat gate valve is closed, it can automatically unload the inner cavity high pressure, and ensure the safe use5., fully enclosed structure, good protection performance, can adapt to all-weather requirements6., the valve seat sealing structure should be elastic, preload, upper and lower sealing seat at the same time sealed structure. The valve seat and the seal are always face to face sealed.The 7. seat has self-cleaning function and is free of direct airflow during valve opening or closing. The seat shall be made of lubricated, non wearing material.8. valve actuator failure will not affect the other parts of the valve, maintenance and replacement work can be carried out without removing the valve.9. yoke sleeve aluminum bronze yoke sleeve with pin type thrust bearing to minimize operation torque.10. stem - thread length until bracket; dowel and spot welding; stability.11. pressure seal - simple construction, with sectional retaining rings and silver plated low carbon steel gaskets, helps to remove and achieve the best bonnet seal.12. seat ring - welded seat ring is perpendicular to the flow channel and is easy to maintain.

- Q: The legend of gate valve and stop valve

- Compared with the cut-off valve, the main advantage is that the flow resistance is small, the flow resistance coefficient of ordinary gate valve is about 0.08~0.12, while the ordinary cut-off valve resistance coefficient is about 3.5~4.5. Opening, closing force is small, the medium can flow in two directions. The disadvantage is that the structure is complex and the height is large. The sealing surface is easy to wear. The sealing surface of the valve must be forced to close the valve to achieve sealing, in the same caliber, work pressure and the same drive device, the drive valve torque is 2.5~3.5 times the gate valve. This point should be noticed when adjusting the torque control mechanism of the electric valve.The sealing surface of the stop valve contacts each other only when the valve is completely closed, and the relative sliding amount between the valve core and the sealing surface is very small, so that the wear of the sealing cover is very small. The sealing surface of the valve cover, mostly due to the spool and sealing surface before the debris, or because of the closed state is not tight, causing the medium of high-speed erosion caused by.

Send your message to us

Gate Valve Non-rising Stem of Best Price and Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords