Gate Valve Non-rising Stem with Top Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

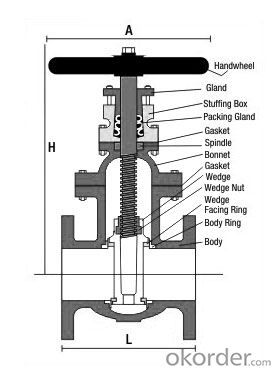

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

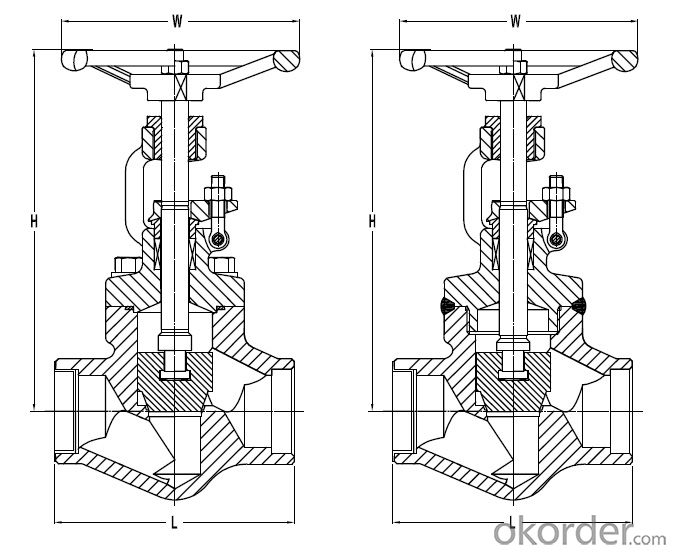

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What gate DH10016, AM

- The first Z represents the gate valve (the initial consonant of the Chinese phonetic alphabet for the gate); the second 2 represents the drive mode of the valve, that is, electro hydraulic drive.

- Q: What valve is z45w gate valve?

- Z = gate valve4 = connection: flange5 = structure form: dark rod typeW = sealing surface material: same as valve bodyDetails: JB/T308-2004 valve model preparation methods

- Q: Does the relief valve have a gate valve?

- The pressure reducing valve group is composed of an adjustable pressure reducing valve, a pressure gauge, a copper valve, a Y filter, a rubber soft joint, a spring pressure gauge, a pressure gauge, an air valve, a pressure gauge and a bent pipe.

- Q: What does gate z41t-10 150 mean?

- According to JB/T308-2004 "valve type programming method"Z gate valve4 flange connection1 Ming wedge single gateT sealing cover material is copper alloy10 nominal pressure PN10PN16 below no marked valve body code, body material is gray cast iron150 nominal size DN150

- Q: Why? God, can you explain to me in detail why?

- Pump outlet, check valve, gate valve.Gate valve plays a regulatory role, is the main pipe. Such a sequence can ensure that the water flow during power failure does not cause damage to the gate valve.

- Q: What is the meaning of socket welding gate valve A105, D&S:STLT, STEM:13Cr, CL800, SW, AP1602, BB-BG-OS&Y?

- Body material: A105Sealing surface material: STLStem material: 13CrPressure rating: CL800Connection: SWImplementation criteria: AP1602BB-BG-OS&Y: plain rod support, bolt connection, flange valve cap.

- Q: What does gate valve do?

- Valve in the pipeline can only be fully open and fully closed off, can not be adjusted and the throttle. Gate valve is a valve used in a wide range, generally more than 50mm caliber DN block device is selected it, sometimes cut off very small aperture devices are used to gate valve, gate valve is used as cut-off media, when in full flow through the whole, when the media is running a minimal pressure loss. Gate valves are normally used in situations where they do not need to be frequently opened and closed, and the gate is fully open or fully closed. Not used as an adjustment or throttling. For high speed moving medium, the gate can cause the vibration of the gate under the condition of partial opening, and the vibration may damage the sealing surface of the gate and the valve seat, while throttling will cause the gate to suffer the erosion of medium.

- Q: Is the gate valve flanged?

- The most commonly used gate valves are threaded connections, flanged connections, and welded connections.Like the outer thread connection, the clamp connection, the card sleeve is seldom used.

- Q: What is the difference between gate valve Z41T and Z45T?

- The difference between Z41T and Z45T is that 41 is the dark rod, that is, the screw is not out of the turbine, and the 45 is the Ming bar, the screw out of the turbine outside, the price is also different?.

- Q: What's the difference between a soft seal gate valve and a hard sealed gate valve?

- The difference is that the form of the gate seal surface is different.General gate valves are generally leaking, easy to rust and other phenomena. Soft sealing gate valve (elastic seat sealing gate valve), gate material for cast iron lining rubber, overcome the shortcomings of the general gate valve, such as poor sealing, elastic fatigue, easy to rust, etc.. Soft sealing gate valve is a new product of the traditional gate valve.

Send your message to us

Gate Valve Non-rising Stem with Top Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords