GATE VALVE NON-RISING STEM METAL SEATED DUCTILE IRON JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China | Model Number: | JIS 10K | Brand Name: | CMAX |

| Shape: | Round | Special Use: | Water | Standard: | JIS, AISI, ASTM, GB, DIN, EN, Other |

| Application: | all sectors | Dimensions: | 40mm to 600 mm | Certification: | ISO/ CE |

| Structure: | Gate | Pressure: | Medium Pressure | Temperature of Media: | Normal Temperature |

Packaging & Delivery

| Packaging Details: | STANDARD/EXPORT PACKING/AS PER CLENTS REQUIRMENT |

| Delivery Detail: | 3-4 WEEKS /AS PER CLIENTS REQUIRMENT |

Specifications

Cast Iron JIS Non-Rising Stem Gate Valve

Certificate:ISO9001,ISO14001,CE,API,KS,GOST

Size from DN40-DN600

Cast Iron JIS-10K Rising Stem Gate Valve

Certificate:ISO9001,ISO14001,CE,API,KS,GOST

Size from DN40-DN600

Face to Face:JIS-10K

Flange:JIS-B2212

Valve Body,Bonnet:Cast Iron

Disc:Cast Iron

Seats:Brass

Stem:SS410

Hand Wheel:Cast Iron

Nominal Pressure:10K

Strength Testing:2.1Mpa

Seats Testing:1.6Mpa

1.Inspection:Foundry in-house; 100% Water Pressure Test ;Third Party inspection available upon request ..

2.Packing: As per the customer requirement .

3.Delivery Date:30 days ; According to the quantity .

4.Payment: 30% by T/T in advance, the balance before Shipping .L/C.D/P.

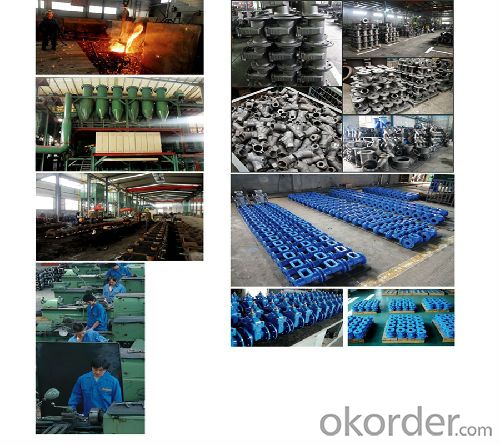

1. 10 years Industry and export experience

2. Extensive product range with good quality

3. Professional laboratory ,research and development team

4. Strictly test and quality control

5. Timely delivery and good after-sale service

6. Produce as per customer requirement

Welcome to contact us !

- Q: The difference between flanged gate valve and common gate valve

- Flange valve: English name; Flange Gate Valve is the gate opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. Gate has two sealing surface, the most commonly used mode gate valve of the two sealing surface to form a wedge, wedge angle with valve parameters vary, usually 50, medium temperature is not high when 2 degrees 52'. Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce micro deformation of ram, in order to improve its process of deviation, make up the sealing surface angle in the process, the gate is called the flexible gate.Ordinary gate valve: mainly used to connect or cut off the medium in the pipeline, not applicable to regulating medium flow. Gate valve applies to pressure, temperature and caliber range is great, especially for medium, large diameter pipesThe most important difference: flange gate valve and ordinary gate valve is different, flange gate valve quality, durable, easy to install, but higher prices, generally used for large pipelines. Ordinary gate valves are used for small caliber, easy to change places.

- Q: What is the standard for ductile iron gate valve set?

- The valve material name, specifications and price according to the facts that the valve rod input line.

- Q: What do you mean by gate valve type RVHX-0150-10 and Z45X-16Q?

- Z45x-16q, Z means gate valve, 4 means flange connection, 5 refers to dark rod gate valve, X means rubber seal, 16 refers to nominal pressure 1.6MpaRVHX means manual gate valve, 150 refers to the caliber of DN150, and 10 indicates nominal pressure of 1.0MPa

- Q: What's the difference between open rod gate and dark rod gate valve?

- There are several differences between the open bar gate valve and the dark rod gate valve:1, the bright bar gate valve can see the screw rod, but the dark rod can not see the lead screw;2, clear shot valve is threaded through the drive rod and the steering wheel to raise or lower the valve; dark rod valve in the switch when the steering wheel is connected with the valve stem is relatively fixed, it is through the stem of a fixed point in the rotation to drive the valve to move up and down to complete the opening and closing of the;Drive screw

- Q: What is the difference between an elastic gate valve and a rigid gate?

- Brief introduction: the valve gate valve is a gate opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. Gate has two sealing surface, the most commonly used mode gate valve of the two sealing surface to form a wedge, wedge angle with valve parameters vary, usually 50, medium temperature is not high when 2 degrees 52'.Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce micro deformation of ram, in order to improve its process of deviation, make up the sealing surface angle in the process, the gate is called the flexible gate.

- Q: Does the tap belong to a stop valve or a gate valve?

- Most taps are stop valves:1, gate valve (gate valve) is a headstock ram, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed doors, discomfort pumpsparameters vary, usually 5 degrees is not high, medium temperature is 2 degrees 52'. To improve its manufacturability, make up for the deviation of the angle of the sealing surface during processing. This gate is called an elastic ram.2, valve (stop, Globe, Valve) of the opening and closing parts are plug shaped valve, sealing surface is flat or sea cone, the valve along the center line of the valve seat in a straight line movement. Stem form of exercise (generic name: dark bar), but also lift rotating rod can be used to control air, water, steam, all kinds of corrosive media, mud, oil, metals and radioactive liquid media and other types of fluid flow. Therefore, this type of shut-off valve is very suitable for cutting or regulating and throttling. Because of the valve stem to open or close the trip is relatively short, but very reliable cut off function, and because changes in the valve seat and the valve stroke is proportional, is very suitable for flow regulation.The stop valve is an ascending stem type, and the handwheel rotates and rises along with the stem. Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open, the cut-off valve is not the same. The gate valve has no inlet and outlet direction requirements, and the cut-off valve has the required inlet and outlet!

- Q: Internal screw current limiting gate valve (Tan Gang) PN5.0 DN15/ Phi 1 Rc1/2 what does that mean?

- We did thatInternal thread current limiting gate valve (Tan Gang)Body material: carbon steelPressure rating: PN5.0 = 300LB American StandardNominal = DN15 = 1/2"Phi 1 = in the middle of the gate drilling a Phi 1 hole, so that in closing there will be a certain flow, that is, the minimum flow, that is, the current limit.Rc1/2 is thread, which is the connection

- Q: What is the Z15T-16C letter of the gate valve?

- The Z class code indicates the type of gate valve, gate valve is the first letter of the alphabet. The gate is manual driving mode, 1 said the connection form of gate valve for connecting thread, 5 represents the structure form of gate valve for rigid single gate, T gate said lining material of copper alloy, 16 PN1.6MPa nominal pressure valve. C said the valve body material is carbon steel.

- Q: Gate valve is gate valve, gate valve specifications, model code is generally what?

- Valve lock valve and gate valve. According to the code, the domestic valve type standard, valve type valve is composed of valve type, drive mode, valve connection, valve structure, sealing material, body material code to said gate type code Z.Gate valve: gate valve is one of the most commonly used shut-off valve, mainly used to connect or cut off the pipeline medium, not used to regulate the flow of media. A wide range of pressure, temperature and diameter is used, especially for medium and large diameter pipes.1, the main characteristics of gate valve(1) fluid resistance is small. The through hole of the gate body is straight through, and the flow direction of the medium does not change when flowing through the medium, so the flow resistance is smaller.(2) opening and closing is more labor-saving. When opening and closing, the direction of valve plate movement is perpendicular to the direction of flow of medium. Compared with the opening and closing more effort.(3) medium flow direction is generally unrestricted. The medium can flow in any direction from both sides and can achieve the purpose of switching on or cutting off. Easy to install, used in the flow direction of the medium may change in the pipeline.

- Q: What does "Z45W-10T" mean?What does each letter stand for?

- W is the seal material or lining material code, the valve sealing material is the valve body material, the valve sealing surface material code with "W" said, here stands for brass;The 10 is the pressure code, which stands for PN10, which is often called 1.0MPa;

Send your message to us

GATE VALVE NON-RISING STEM METAL SEATED DUCTILE IRON JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords