GATE VALVE AWWA/ ANSI NON-RISING STEM RESILIENT SEATED DUCTILE IRON

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Low Pressure |

Power: | Manual | Material: | Casting | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | Standard | Place of Origin: | China (Mainland) |

Model Number: | Z1703111 | Brand Name: | CMAX | Application: | General |

Body: | DI | Disc: | DI+EPDM | Stem: | Stainless Steel |

Stem Nut: | Bronz | Bonnet Gasket: | EPDM | Nut: | WCB |

Bolt: | WCB | Bonnet: | DI | O Ring: | EPDM |

Gland: | DI |

Packaging & Delivery

Packaging Details: | plywood case or fumigation wooden case |

Delivery Detail: | 30 days |

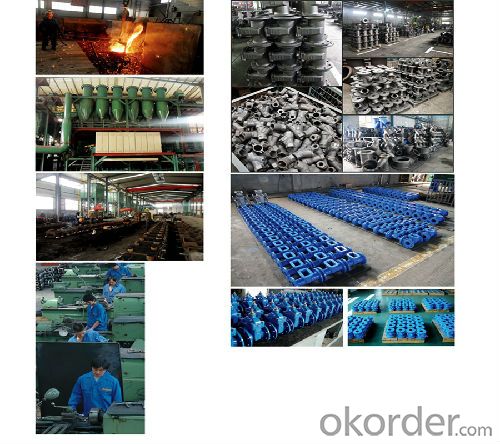

AWWA/ANSI 250Psi Non-Rising Stem Metel Seat Gate Valve

Features

Replaceable O-ring

Low torque operation

Rubber encapsulated wedge

Clockwise closing direction

Fusion bonded epoxy coated inside and outside

Product color:Bule RAL 5017

Temperature:33-125 °F/0.6-52 ℃(AWWA C509)

Technical Specification

Design:AWWA C515/C509 250Psi

Face to Face:ANSI B16.10

Flanges:ANSI B16.1 Class125

Work Pressure:3-12inch;200Psi

16-30inch:150Psi

Hydraulic test :AWWA C509

Seat :250Psi

Shell:500Psi

- Q: What is a protective gate valve? What is gate valve knowledge?

- Explosion-proof valve products, is a kind of safety valve can eliminate the shock wave which can stop the water hammer shock wave, it is a product composed of multiple sets of safety,

- Q: What's the difference between open rod gate and dark rod gate valve?

- 3, dark rod valve is located inside of the body, in the process of opening and closing, stem only rotation move, the gate in the valve body lifting; the valve stem rod driven gate valve with the valve stem of the lifting drive thread in the external body, according to the direction of movement of the stem and the position of judge the gate opening and closing and position;

- Q: Stainless steel gate valve DN150 200300 weight, who knows?

- The weight of DN150/200/300 is 134/192/379kg. Of course, different manufacturers may vary in weight, but not much.It's not that heavy at all

- Q: Is the gate valve clockwise or closed?

- Usually it's off. There are some special occasions. It is said that the plane uses a lot of counter

- Q: What's the difference between the knife gate valve and the stop valve?

- Standard light valve professionals to answer for you, gate valve refers to the closure of parts (gate) along the central line of the vertical direction of moving valve. The gate valve is mainly used for cutting in the pipeline. The valve is a valve with a very wide, cutting device general caliber DN = 50mm use it, sometimes a small diameter cutting device also use valve, gate valve has the following advantages:Fluid resistance is small.

- Q: What's the meaning of flexible z45x-10q door valve?

- Crown valve pressModel Z45X-10QZ refers to gate valve4 finger flange connection5 refers to the dark bar driveX refers to rubber seals10 refers to 10 kg pressureQ refers to the body material, ductile ironFull bore flange soft sealed gate valve

- Q: About fire valve is gate valve or butterfly valve problems?

- Disease is generally in accordance with the design requirements, regardless of the butterfly or tie hair to meet the requirements, are two-way valve.

- Q: What is plug welding gate valve?

- Socket welding valve valve cover design in three forms. The first is forging steel bolt type valve cover, according to this design form design of the valve, the valve body and the valve cover bolt nut connection, spiral wound gasket 316 clamp flexible graphite manufacturing: seal. Customers have special requirements can be used when the metal ring connection. Second design form is the welded bonnet, according to this design form of the valve, the valve body and the valve cover with a threaded connection, welded seal. Customers have special requirements can be used when the third is connected through welding. Self sealing valve cover, according to this design form design of the valve, the valve body and valve cover with a threaded connection, pressure from the dense ring seal.The editing characteristics of 1 valve design and manufacture in accordance with API602 and ASME B16.34. tested according to API 598, marked by MSS-SP-25.2. full diameter or diameter shrinkage 3 rod bracket type 4 self centering sleeve type 5 pressure plate bolt connection, spiral wound gasket seal type valve cover nut connection, welded seal type valve cover and screw connect the internal pressure self tightening type valve cover 6 integral sealing seat 7 socket end with ASME B16.118. threaded end (NPT) with ANSI/ASME B1.20.19. valve can be transformed into the throttle type, needle type, ball type and type check

- Q: What is wire feed gate valve? What do you say in French?

- Should refer to the threaded valve. Refers to the valve body with internal thread or external thread, and pipe thread connection. Also called thread valves, threaded valves, valves within the toothFlange gate valve is connected to the flange gate valve, this connection is the most common way.We also introduced a lot of threaded valve, can go to the front pages.The main difference is the threaded valve connectionI only know their English, I'm sorry I can't help youBox thread valveFlange valveThreaded valve, screw connected with the valve, should be said that the former is the most professional.

- Q: What is the difference between gate valve 41h-16c and 41w-16p?

- The difference between 41h-16c and 41w-16p is that the material of the valve body and the material of the sealing surface are different.According to the provisions of the JB/T 308-2004 valve type programming method:H== sealing surface material: Cr13 stainless steelC== body material: carbon steelW== sealing surface material: body, that is, with the same material bodyP== body material: chrome nickel stainless steel

Send your message to us

GATE VALVE AWWA/ ANSI NON-RISING STEM RESILIENT SEATED DUCTILE IRON

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords